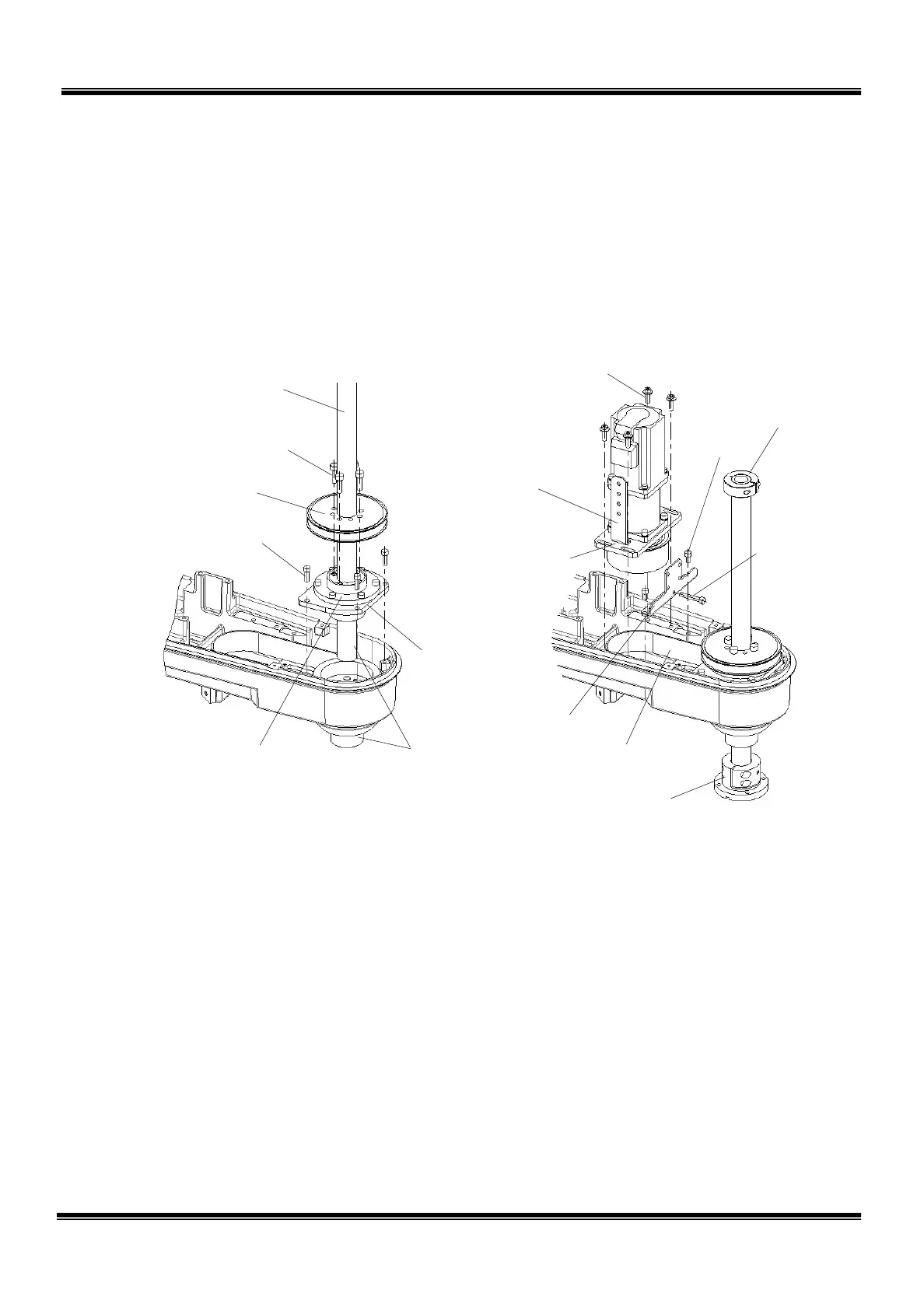

14) Attach the tool flange and stopper to the ball screw shaft.

15) Attach the guide to the arm 2 with the two (2) bolts (M5 × 10).

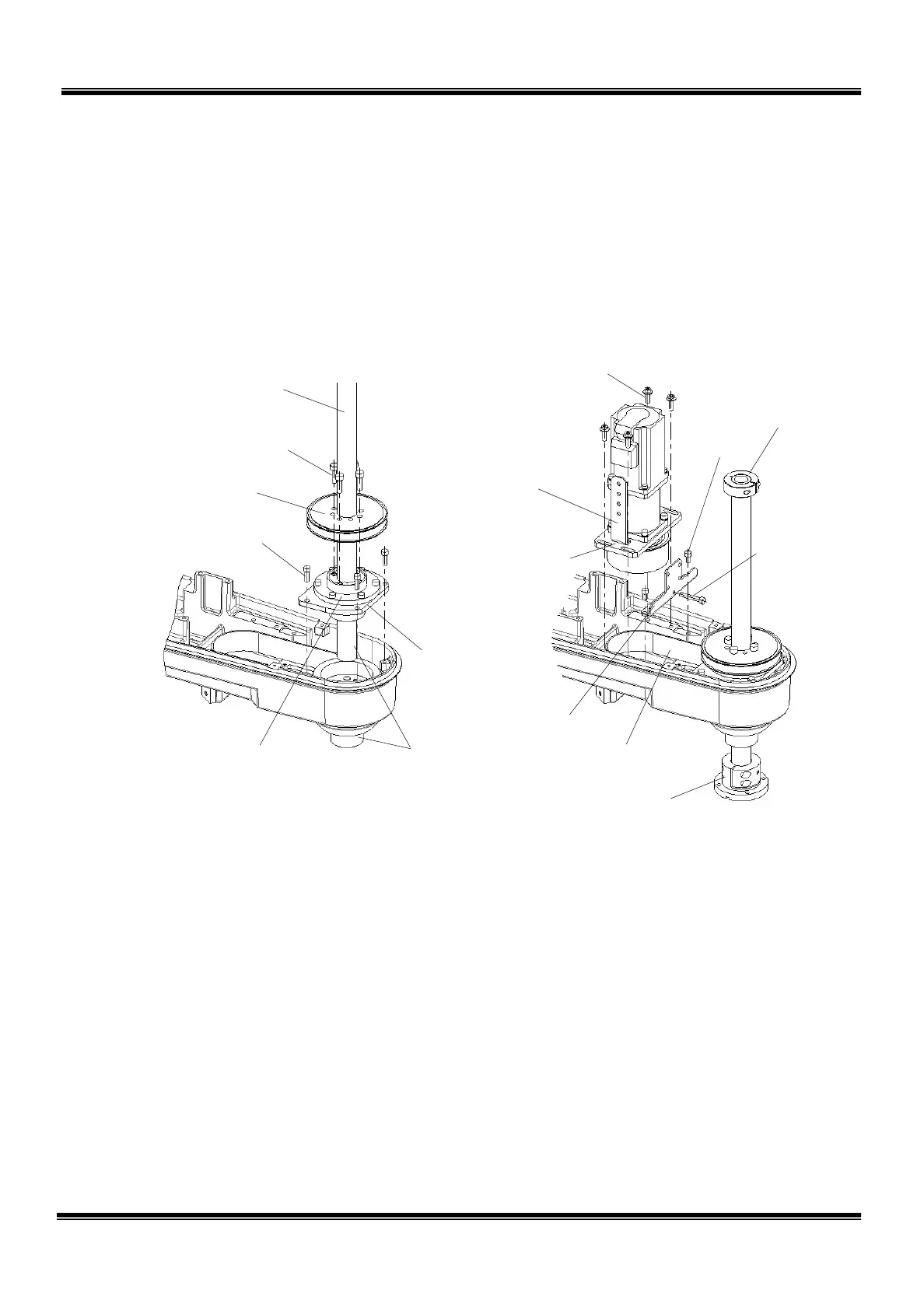

16) Temporarily set the motor base which was disconnected in Step 6) above to the

arm 2 with the four (4) flange head bolts (M5 × 16) after setting the axis 4 timing

belt to the axis 4 motor pulley. Also mount the axis 4 tension adjustment bolt

(M5 × 30).

17) While pushing the axis 4 motor base by means of the axis 4 tension adjustment

bolt, measure the tension on the tension meter. At a position where the

tension has reached 320 to 380 N, tighten the flange head bolts.

The values used for the tension meter are tabled below.

M6×20

Recommended clamping

torque: 17 N·m

M5×16

Recommended clamping

torque: 8.8 N·

M5×16

Recommended clamping

torque: 8.8 N·

Align the phases

and insert.

STE 85306

– 51 –

Loading...

Loading...