Piping and Connections

102 CLCH-SVX07K-EN

recommends installing a plug to facilitate cleaning of the

trap. The drain connection sizes are:

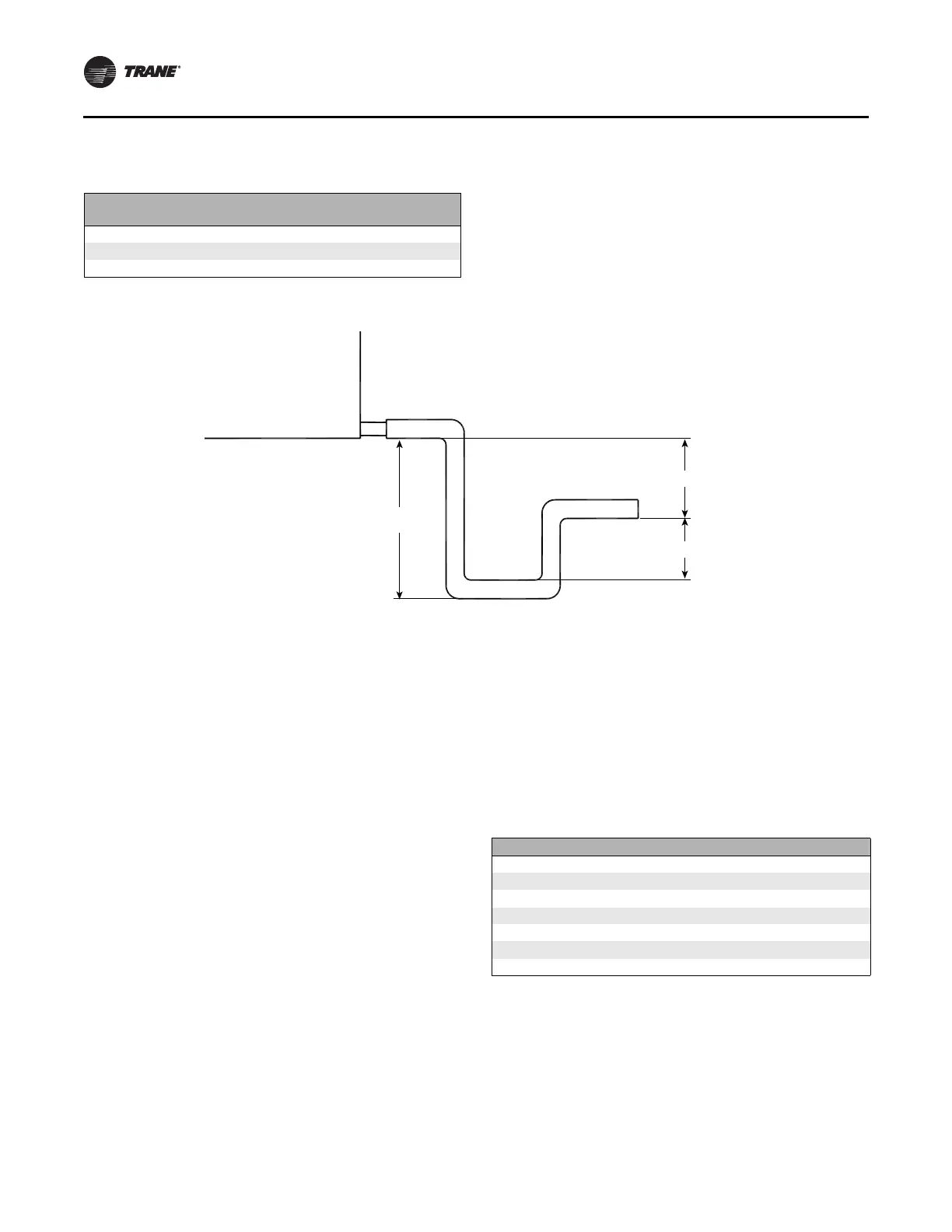

Figure 35 illustrates the proper trapping, piping, and

operation of the trap. Use the formula under the figure to

determine the correct minimum depth for the condensate

trap. If a section has a drain pan for cleaning purposes

only, it does not need a trap; however, a cap or shutoff

valve should be installed on the drain connection. Only

sections handling condensate, such as a cooling coil

section or moisture eliminator section, require a trap.

Steam Coil Piping

Air handlers fitted with steam coils have labeled holes for

piping penetrations. Figure 133 illustrates a typical steam

coil piping configuration. See Table 36 for the codes of

system components in these figures.

The coil condensate return line must be piped full size of

the condensate trap connection, except for a short nipple

screwed directly into the coil header’s condensate return

tapping. Do not bush or reduce the coil return trapping

size.

Unit size

NPT (national pipe thread) external

connection

3-30 1-inch

35-57 1 1/4 inch

66-120 1 1/2 inch

Table 35. Drain pan trapping for negative and positive pressure applications

H

J

L

Drain pan trapping for section

under negative pressure

L = H + J + pipe diameter where:

H = 1 inch for each inch of negative

pressure plus 1 inch

J = 1/2 H

Drain pan trapping for section

under positive pressure

L = H + J + pipe diameter where:

H = 1/2 inch (minimum)

J = 1/2 inch plus the unit positive static

pressure at coil discharge

(loaded filters)

Negative pressure Positive pressure

Table 36. Code of system components for piping figures

Code System component

FT Float and thermostatic steam trap

GV Gate valve

OV Automatic two-position (ON-OFF) control valve

VB Vacuum breaker

ST Strainer

AV Automatic or manual air vent

MV Modulating control valve

Loading...

Loading...