Installation - Mechanical

32 CLCH-SVX07K-EN

5. Assemble and seat connections per color code.

6. Wrap each connection individually with black electrical

tape.

7. Fully wrap the connection with tape.

8. Use a bar clamp to pull adjacent shipping section lifting

lugs together.

9. For indoor units sizes 66-120 and for outdoor units size

35-120, a wedge block is provided to aid in pulling and

aligning the units together. Attach the wedge blocks to

both sides of the units being pulled together, matching

the correct wedge block with the correct hole pattern.

See Figure 40, p. 34.

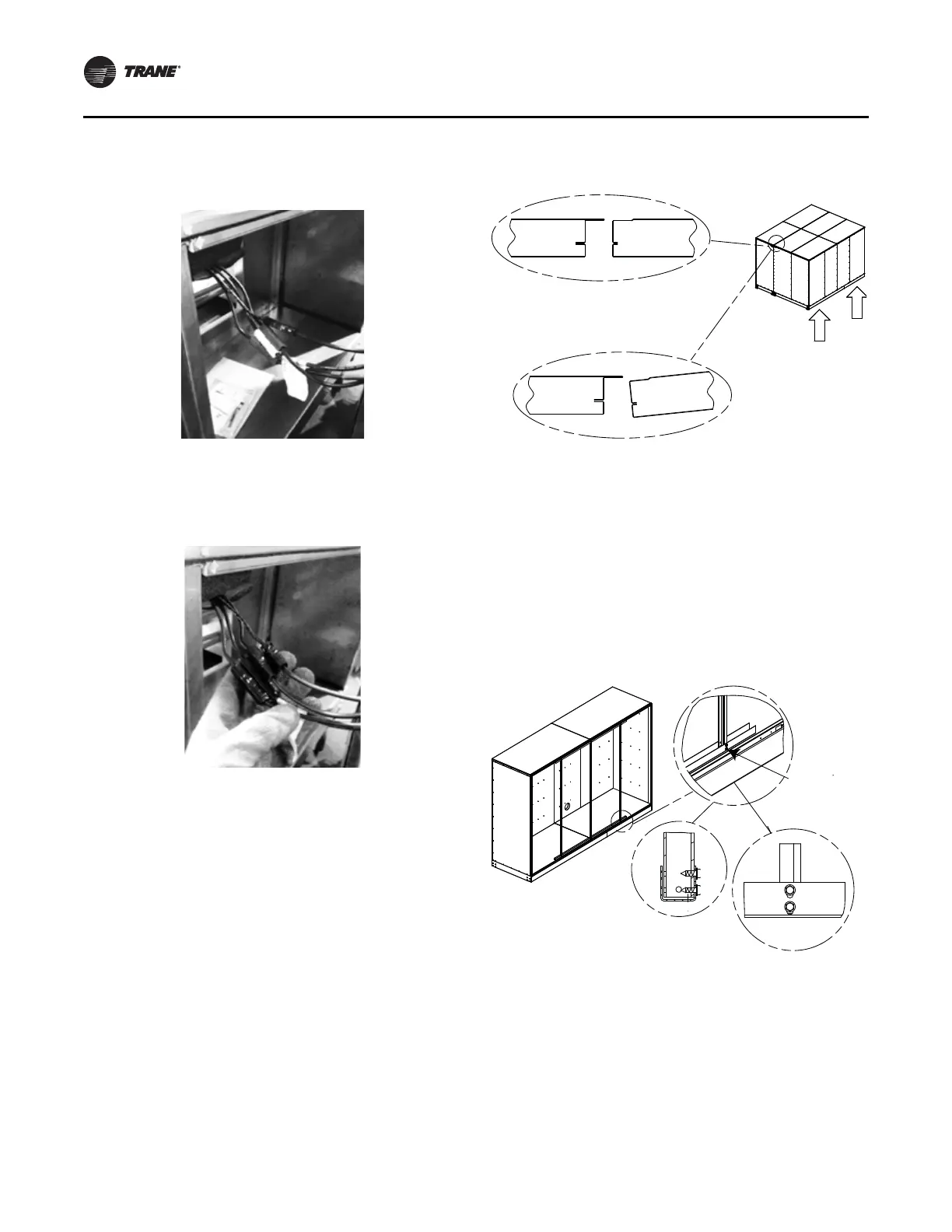

10. Verify that the subassembly with the overhang profile

on the roof is higher than the mating subassembly. If it

is not, raise one end of the subassembly and bring the

unit together. See Figure 37.

11. Due to unlevel floor and platforms, the roof may be

misaligned as shown in Figure 37. A common solution

is to raise one end of the shipping section to clear the

hemming before pulling the units together.

12. In addition, an adjustment can also be made to the

height of the roof of either subassembly. At the center

(width-wise) of the unit, measure the height of each

adjacent subassembly and verify that the subassembly

with the overlap sheet metal is higher than the mating

subassembly roof. If it is not, adjust the height of either

subassembly by loosening the screws in the vertical

channels or component structure and adjust the height

of the roof. See Figure 38 and Figure 39).

Figure 35. Horizontal section-to-section high voltage

quick connects

Figure 36. Horizontal section-to-section high voltage

quick connects

Figure 37. Roof alignment (indoor unit only)

Figure 38. Adjust height of roof by adjusting vertical

channels

Loosen screws

along width of

unit for roof

height

adjustment.

Loading...

Loading...