Routine Maintenance

154 CLCH-SVX07K-EN

CDQ Seal Adjustment

Neoprene brush seals are located on both sides of the

cassette around the wheel perimeter and the center

diameter posts. The seals are designed to come in contact

with the wheel and require no maintenance other than

adjustment. The seals consist of a metal and neoprene clip

that grips to the metal posts or panels. These clips can be

manually adjusted.

To minimize air that bypasses the wheel the perimeter

seals should be adjusted such that air gaps are not visible

around the wheel. Do not over compress the seal against

the perimeter as this may cause the wheel not to turn or

overload the motor. To minimize air the leaks from one

side to the next the diameter seals should be adjusted to

come in full contact with the wheel face.

CDQ Drive Motor and Pulley Replacement

1. Disconnect all electrical power.

2. Remove the belt from the pulley and temporarily

position it around the wheel rim.

3. Measure and record the distance from the inner edge

of the pulley to the mounting wall.

4. Loosen the set screw in the wheel drive pulley using an

Allen wrench and remove the pulley from the motor

drive shaft.

5. While supporting the weight of the drive motor in one

hand, loosen and remove the four mounting bolts.

6. Install a replacement motor with the hardware kit

supplied.

7. Install the pulley and adjust it to the distance recorded

in the previous step.

8. Tighten the set screw to the drive shaft.

9. Stretch the belt over the pulley and engage it in the

groove.

Energy Wheels

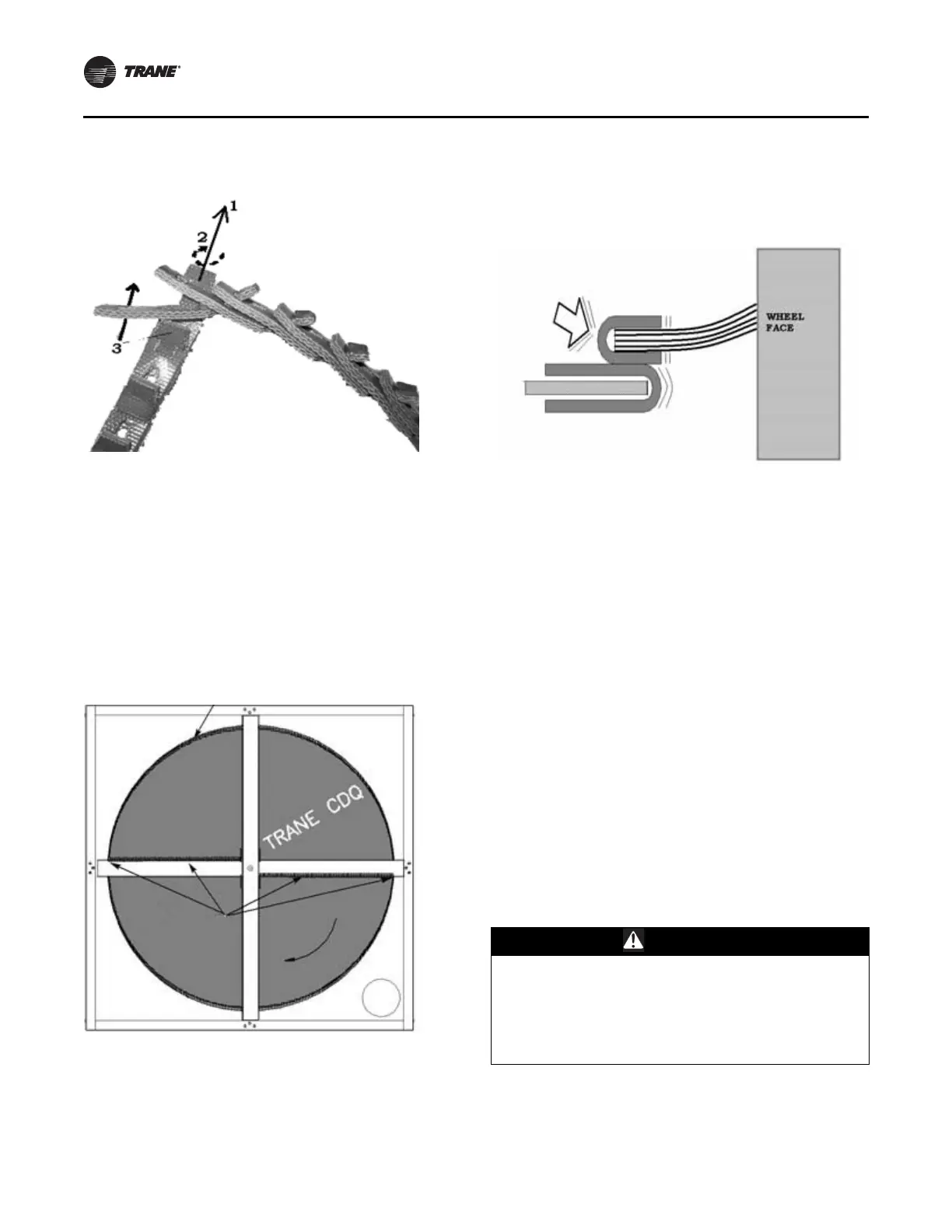

Figure 192. Reconnect the belt

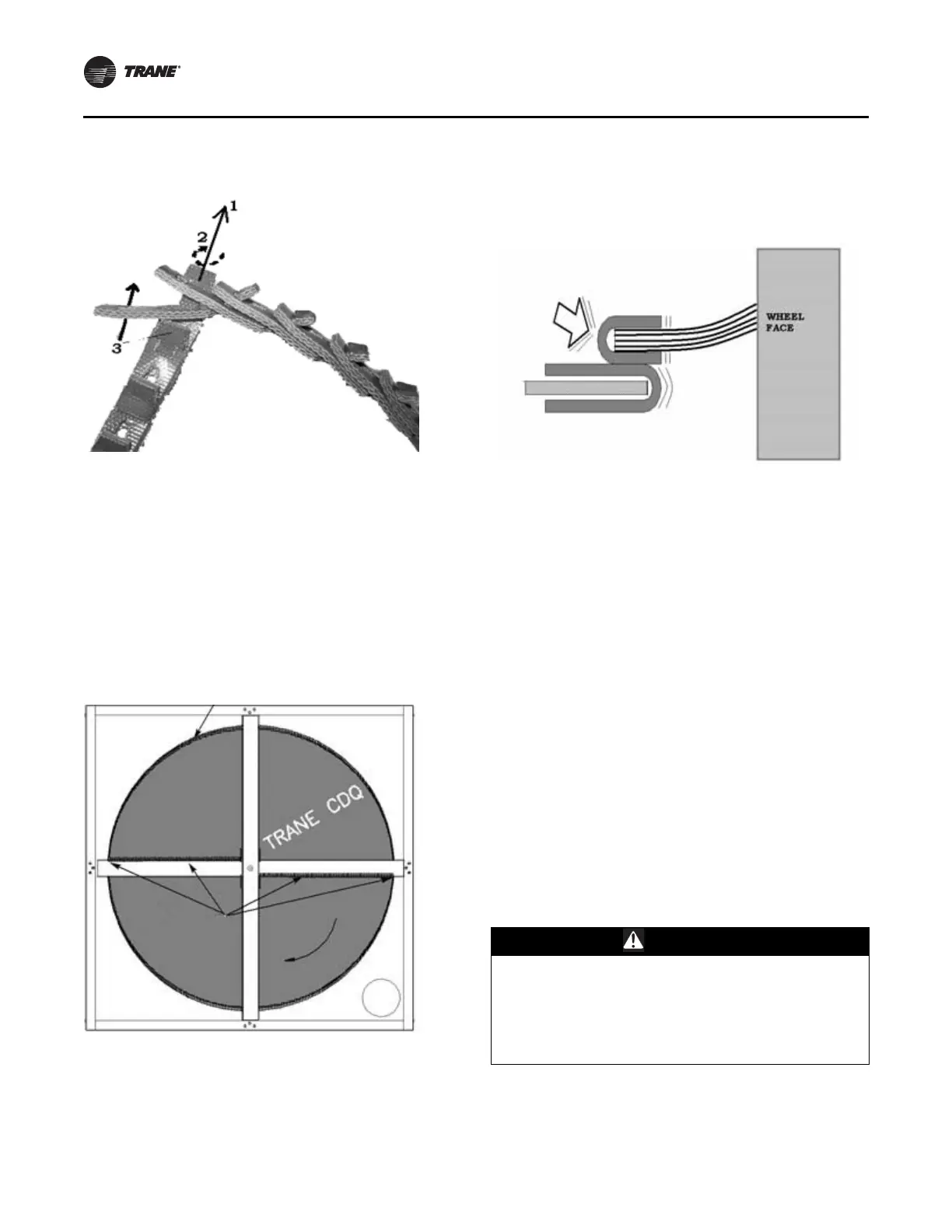

Figure 193. Seals are located around wheel perimeter

and center of diameter posts

Perimeter seals

Diameter

seals

Figure 194. Adjust seals to fully contact wheel face to

minimize leaks

WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury. Disconnect all electric

power, including remote disconnects before servicing.

Follow proper lockout/tagout procedures to ensure the

power can not be inadvertently energized.

Loading...

Loading...