Installation - Mechanical

CLCH-SVX07K-EN 43

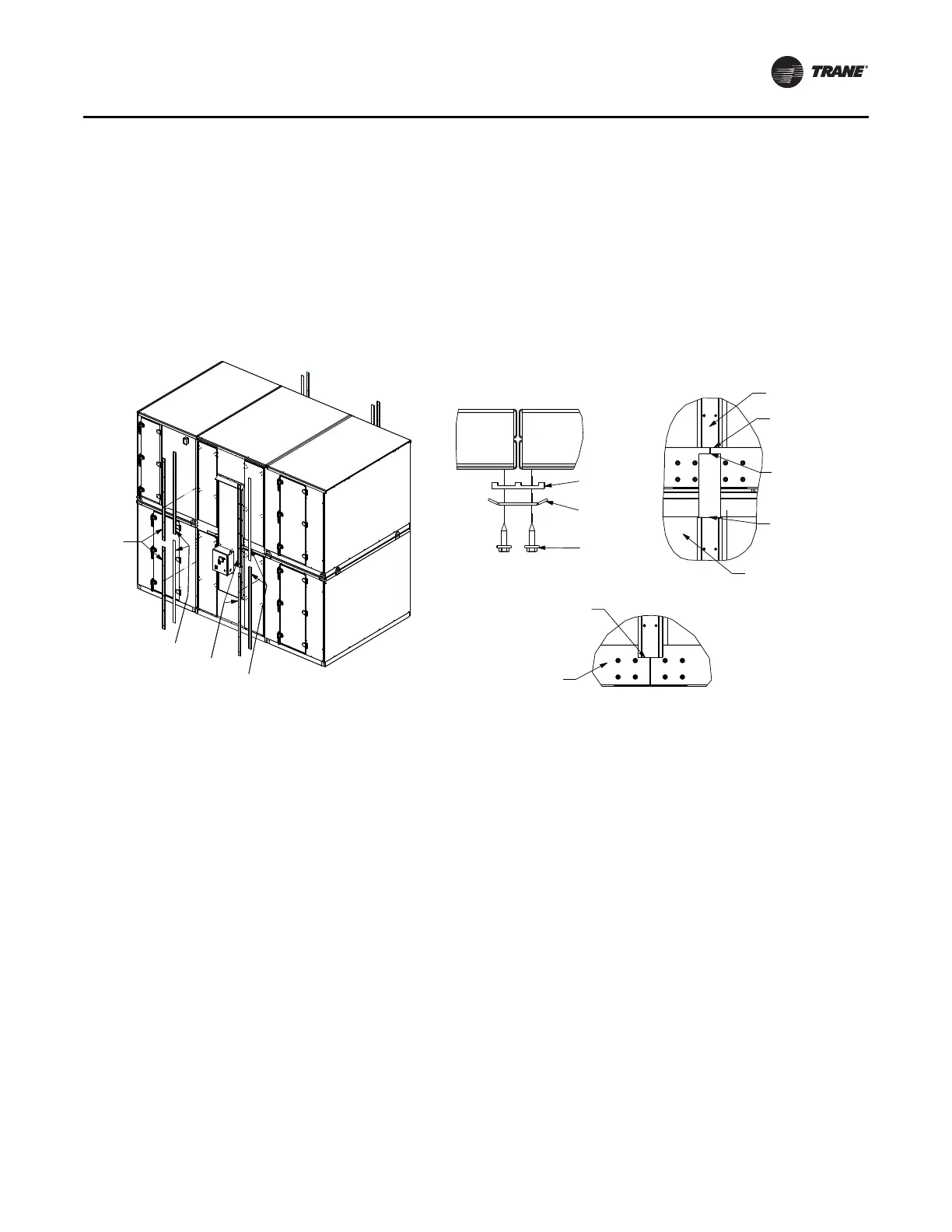

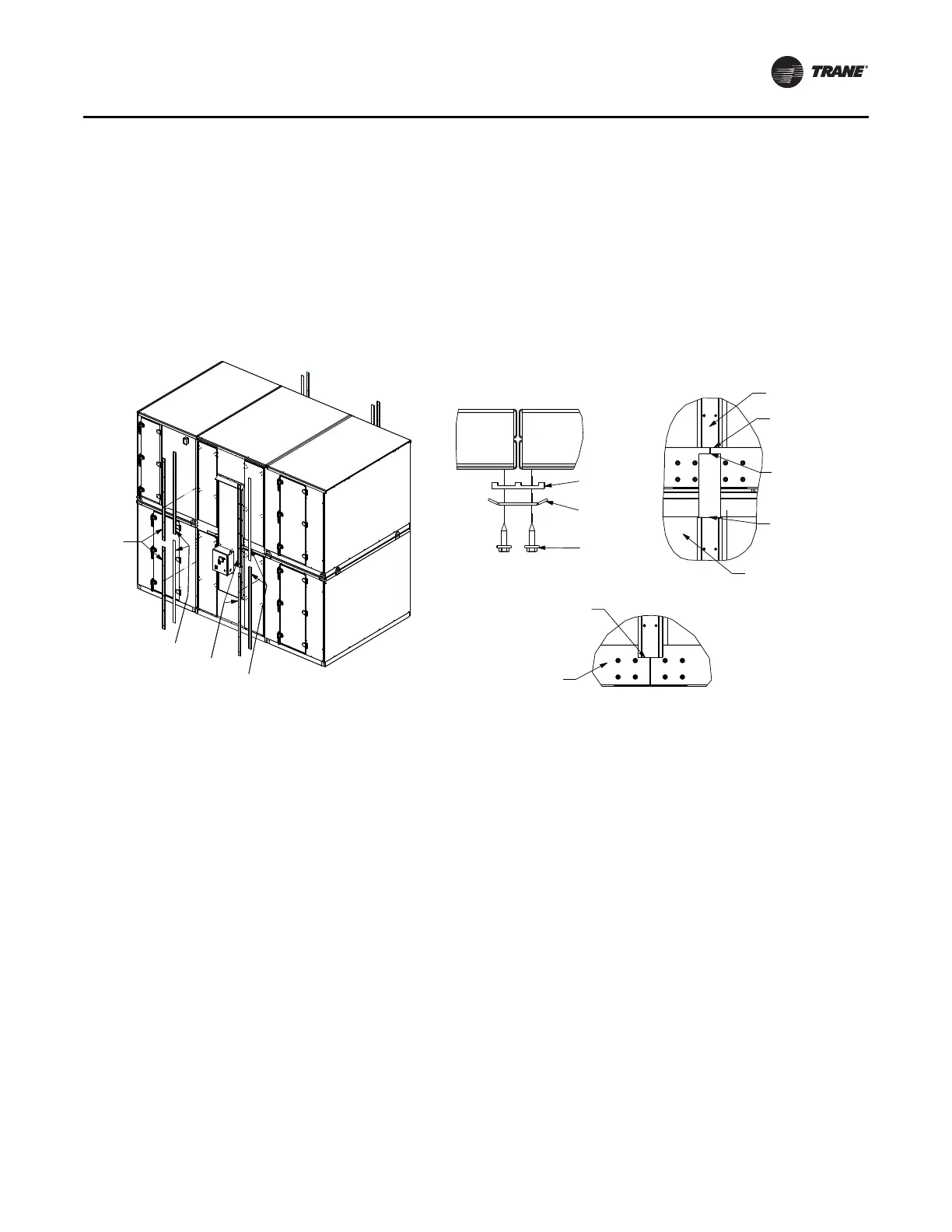

Vertical Seam Cap Installation

1. See Figure 50. Apply ribbed Butyl tape (Item 6) over all

vertical shipping split seams (see Detail A). First level

ribbed Butyl tape (Item 6) starts 1/2 inch below second

level wall panel (see Detail B), and extends down

beyond the bottom of the first level wall panel onto the

base rail at least one inch (see Detail C). Second level

ribbed Butyl tape (Item 6) starts at bottom of wall panel

on second level (see Detail B) and runs up to the top of

the second level wall panel.

2. Secure vertical seam cap (Item 7) over ribbed Butyl

tape (Item 6) with screws (Item 4) (see Detail A). First

level vertical seam cap (Item 7) starts at bottom of hem

on roof panels (see Detail B) and extends down onto

the base rail at least one inch (see Detail D in Figure 55).

Vertical seam cap (Item 7) on second level starts at

bottom of wall panel and extends up (see Detail B).

Second level vertical seam cap (Item 7) may extend

onto the roof panel.

Flashing Installation

For additional information, see “Flashing Installation

Notes,” p. 48.

For hood installations, see “Install Flashing and Hood,”

p. 49.

1. See Figure 51. Apply Butyl tape (Item 8) to

perpendicular-to-airflow flashing (Item 9) and secure

to base rail with screws (Item 4) on front and back of

unit (see Detail A in Figure 55).

2. For energy wheel/CDQ wheel, preassemble end covers

(Item 10 and Item 11) to direction-of-airflow flashing

(Item 12) with screws (Item 4). Apply caulk (Item 14) to

create water tight seal (see Detail B in Figure 53).

3. Apply Butyl tape (Item 8) to direction-of-airflow

flashing (Item 12) and secure to base rails with screws

(Item 4). Start at corners to ensure tight corner seams.

Apply caulk (Item 14) to create water-tight seal (see

Detail A and Detail C in Figure 54).

4. Install seam covers (Item 13) to all flashing seams (see

Detail D in Figure 55).

If second level of unit is shorter than first level, see

“Flashing Installation for Stacked Unit With Second Level

Shorter Than First,” p. 46.

Figure 50. Vertical seam cap installation

(7) Plate:

Vertical

seam cap

(6) Tape:

Ribbed Butyl

(7) Plate:

Vertical

seam cap

(4) Screw:

10-16 x 0.750

self driller

(6) Tape:

Ribbed Butyl

(7) Plate: Vertical

seam cap

(6) Tape:

Ribbed Butyl

Shipping split seams

Detail B

Ribbed Butyl tape and

seam cap flush with

bottom of wall panel

First level ribbed

Butyl tape 1/2 inch

below second level

wall panel

First level seam cap

starts at bottom of

hem on roof panel

First level

Ribbed Butyl tape and seam

cap extend beyond the bottom

of wall panel onto base rail at

least one inch

First level

Second level

Detail C

Detail A

Loading...

Loading...