Installation - Electrical

118 CLCH-SVX07K-EN

If not factory-installed, the electrical contractor must

provide and install a starter or starting contactor,

disconnect, fuses, etc., as required by local codes, for the

CDQ wheel motor. Do not install a variable frequency

drive (VFD) to control the desiccant wheel speed. This

may result in failure of the wheel motor. The motor

requires air movement for continuous operation.

Operating the wheel for long periods with the fan off may

result in motor failure.

Optional Damper Actuators

Each actuator requires 24 Vac supply power and wiring for

the 2–10 Vdc control signal. This wiring should be sized

and installed as required per national and local electrical

codes.

Optional Air Temperature Sensors

If not factory-wired, connection to the air temperature

sensors is made by penetrating through the side of the

module wall and making electrical connections to the

temperature sensor. Nominal resistance of these sensors

is 1,000 ohms at 32 degrees F (0 degrees C). The sensor is

a thermistor with a platinum 375 resistance curve. This

wiring should be sized and installed as required per

national and local electrical codes.

Table 37. CDQ motor data

Wheel Size

(nominal cfm) HP Voltage/phase HZ Full Load Amps Rotation RPM Rotation Direction

500-5000 1/80 115 Volt Single Phase 60 0.3 2.30 CW/CCW*

6000-40,000 1/80 115 Volt Single Phase 60 0.3 4.50 CW/CCW*

Note: *Motors are wired for counter-clockwise rotation

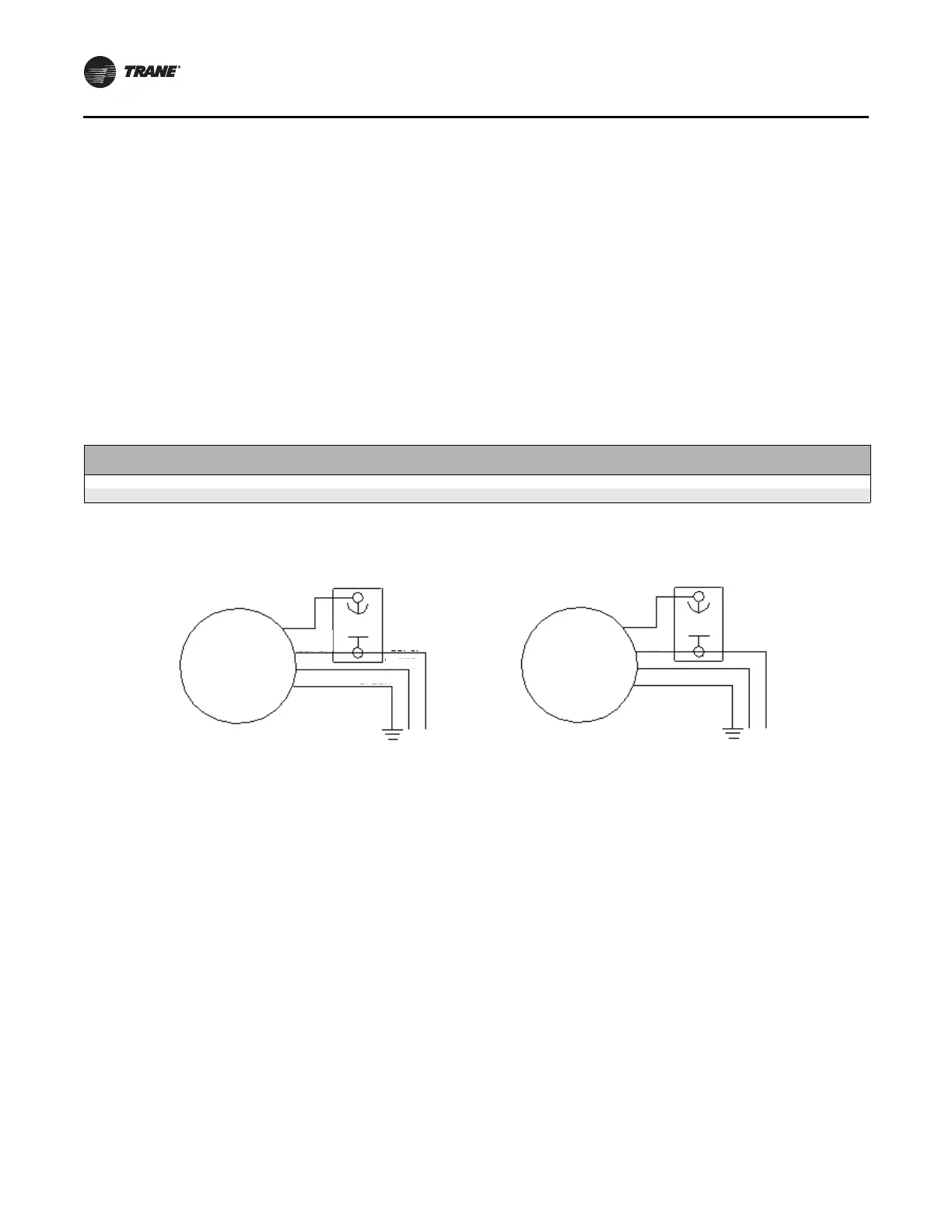

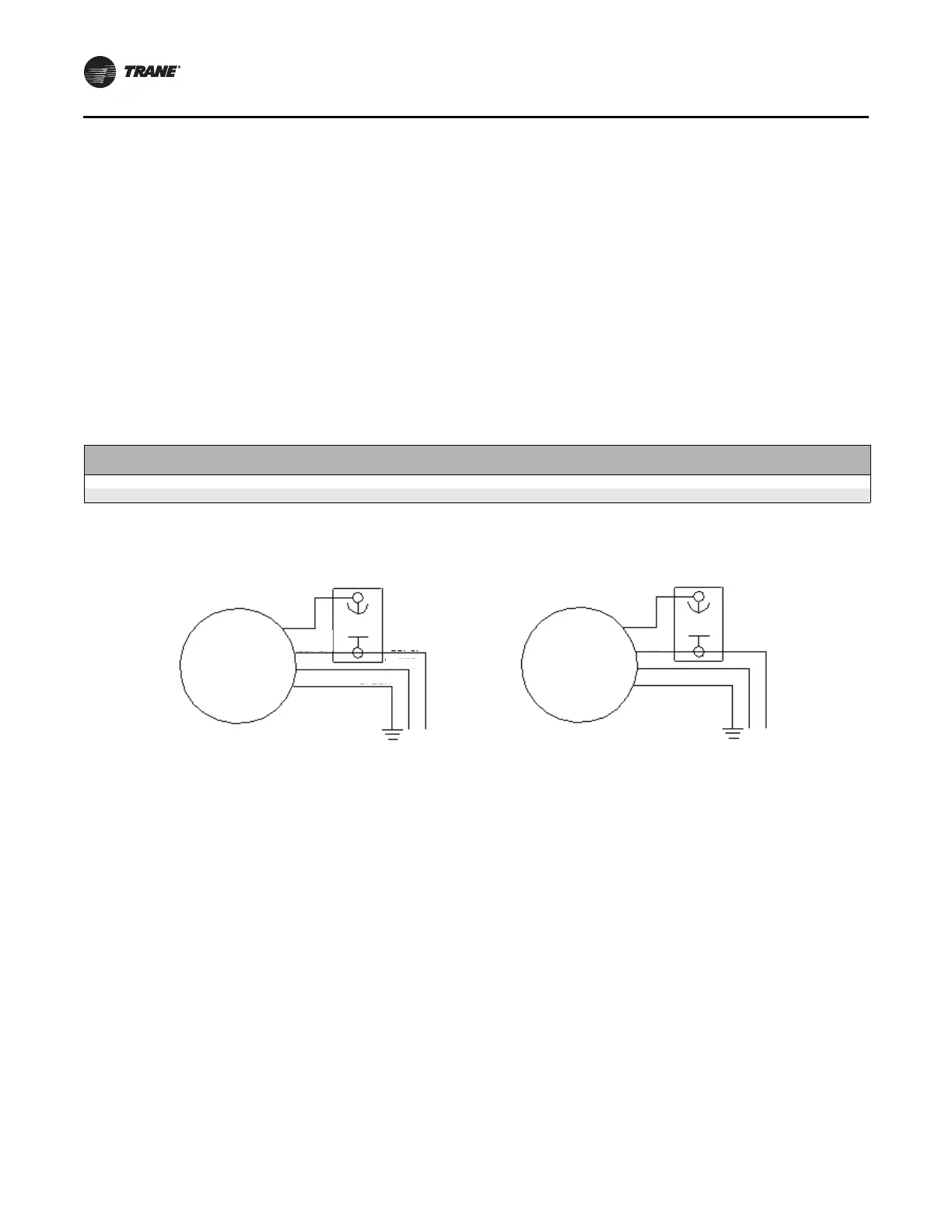

Figure 154. CDQ motor wiring

Red

BlackBlack

White

Green

Black

Red Black

White

Green

MM

5000C 1 wheels and below

≤48 in. diameter

6000C1 wheels and above

≥54 in. diameter

Loading...

Loading...