AU-OPR-AureFloFT-EN,

Rev H

15

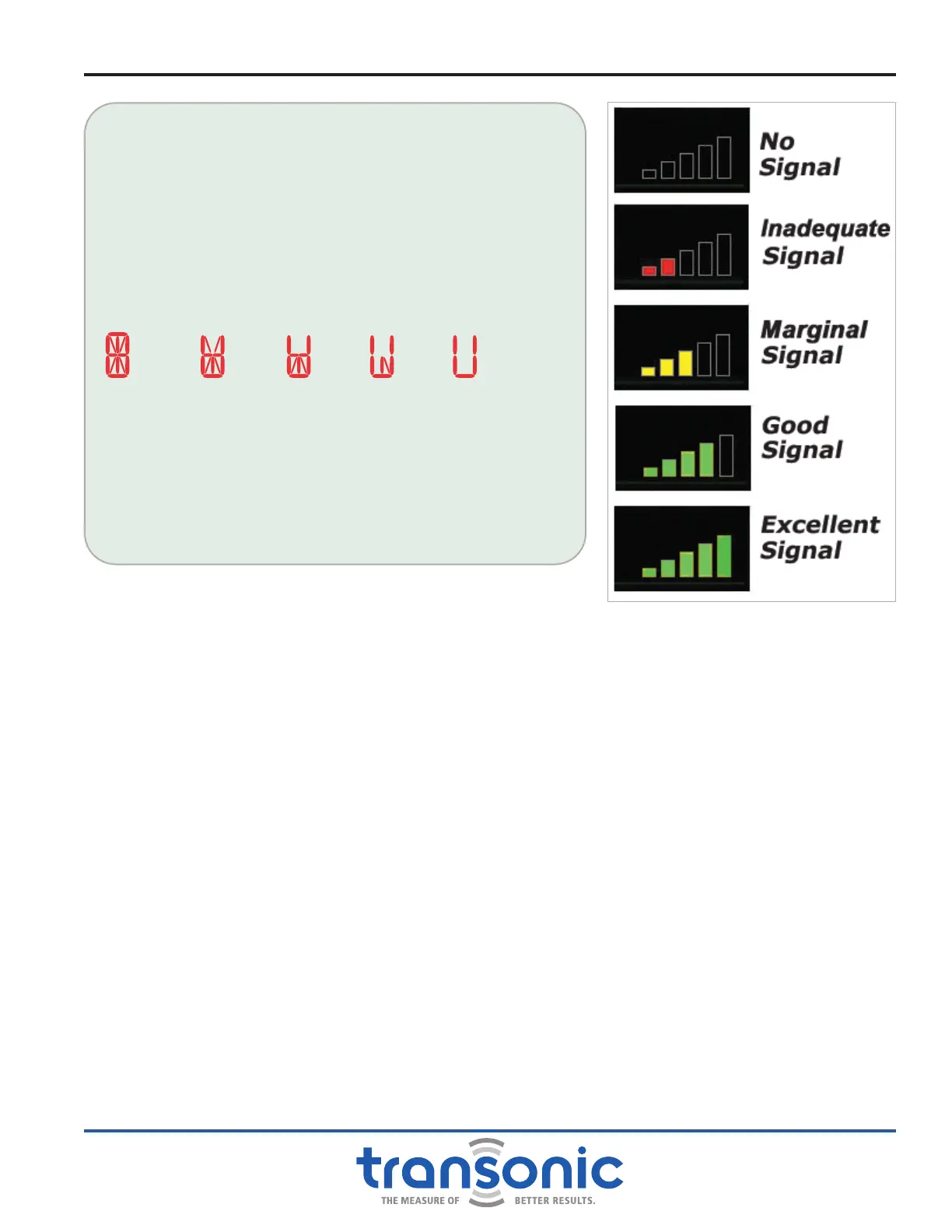

Fig. 4.5: Progression of signal indicator bars

as ultrasonic signal coupling is

achieved. Four green bars indicates a

signal strength ≥ 50% for a factory-

new condition of the Probe/sensor,

acceptable for continued surgical use.

E. Testing The Clamp-On Flowsensor

Perform this test on a uid-lled tubing circuit or a one foot tubing

segment, clamped at one end and lled with water.

IMPORTANT: DO NOT IMMERSE THE CLAMP-ON FLOWSENSOR IN LIQUID.

1) Lubricate the tubing with a thin layer of 70% isopropyl alcohol or surgical gel to promote ultrasonic

transmission.

2) Place the tubing inside the Flowsensor and close the door of the Sensor. The tubing slot will reshape the

tubing to a rectangular shape.

3) Observe the Signal Indicator in “Realtime” mode. The bars will change color from black to red to yellow

to green as the strength of the signal increases and acoustic transmission is attained (Fig. 4.5).

4) When a Flowsensor is connected and there is adequate ultrasonic transmission, ow can be measured.

This is indicated by a waveform on the scrolling bar of the touch-panel display.

Functional Tests

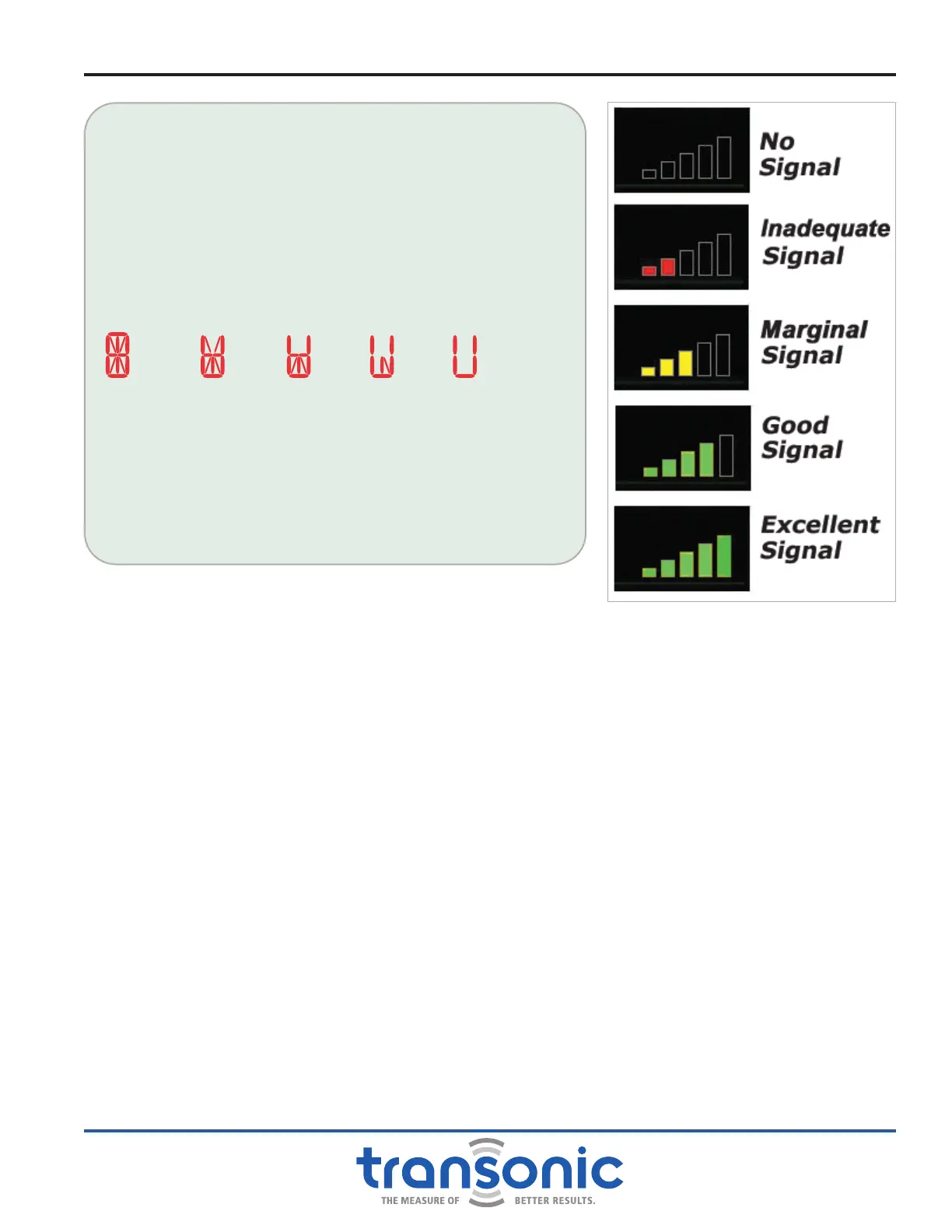

FLOWMETER SIGNAL QUALITY

Signal strength is used to indicate whether a probe is properly

applied; if the probe is properly applied, a low signal strength

does not have any impact on ow accuracy. If your meter displays

30% signal strength, check for the following:

● Air bubbles or other blockages obstructing the ultrasound

signal

● Sufcient couplant within the probe’s sensing window

Once these issues are resolved, measurement can be considered

in tolerance even at signal strength readings of 15%.

100% 75% 50% 30% 15%

Another factor for low signal strength may be:

● Probe condition (wear on handle, reector, connector, etc.)

Contact Transonic for replacement/repair if there is obvious

damage. A received signal reading approaching 15% (while

properly applied) indicates that it is time to consider replacing

this probe.

If Flowmeter's front panel reads NO SIGNAL, contact Transonic

for probe replacement/repair.

Loading...

Loading...