SCRAPER RING/TUNGSTEN SLIDING BLOCK MAINTENANCE

Maintenance of the scraper ring or tungsten sliding block may

be required if the following problems are encountered while

using the gauge:

F. MAINTENANCE

♦ Difficulty in lowering or raising the source rod (may indicate a need to

replace the scraper ring).

♦ No “click” is heard from the tungsten sliding block striking the back of

the shield cavity when the source rod is raised to the “safe” position.

♦ Erratic or incorrect density standard counts.

Model 3440-L F–5

WARNING

Routine maintenance to clean the cavity beneath the

source requires removal of the bottom sliding block.

ALWAYS wear safety glasses and a dosimeter.

Procedure – Scraper Ring/Tungsten Sliding Block Maintenance

1. With the source rod in the SAFE position, place gauge on its side.

2. Clean the heads of the four screws to make removal easier and to

prevent the screw heads from stripping.

3. Using a screwdriver, remove the bottom plate. Replace if excessive

wear is evident on the back of the bottom plate.

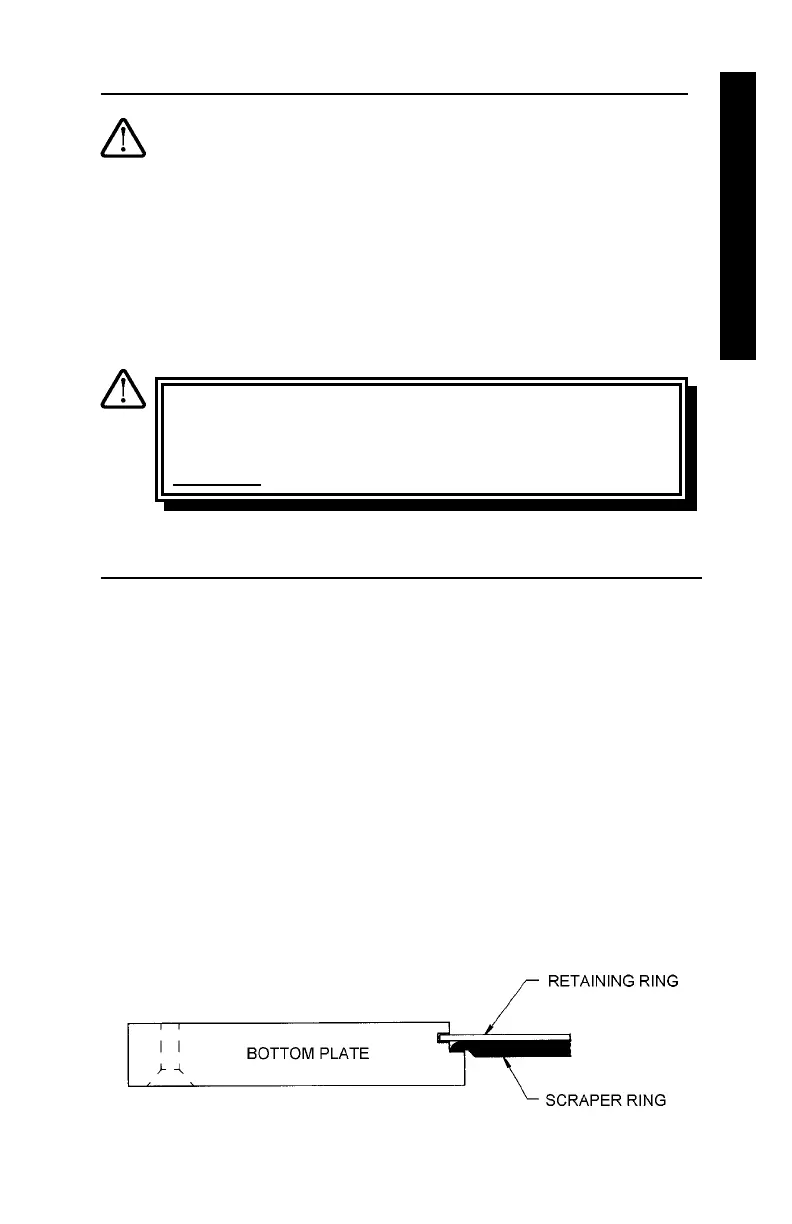

4. If a large amount of dirt has accumulated on the backside of the

bottom plate, the scraper ring has become excessively worn and

should be replaced. Replace the scraper ring by first removing the

retaining ring with a small screwdriver or scribe (Figure F–1).

Carefully remove the scraper ring. Clean the entire plate of any debris.

Install the new scraper ring and replace the retaining ring.

Figure F–1. Retaining and Scraper Rings

Loading...

Loading...