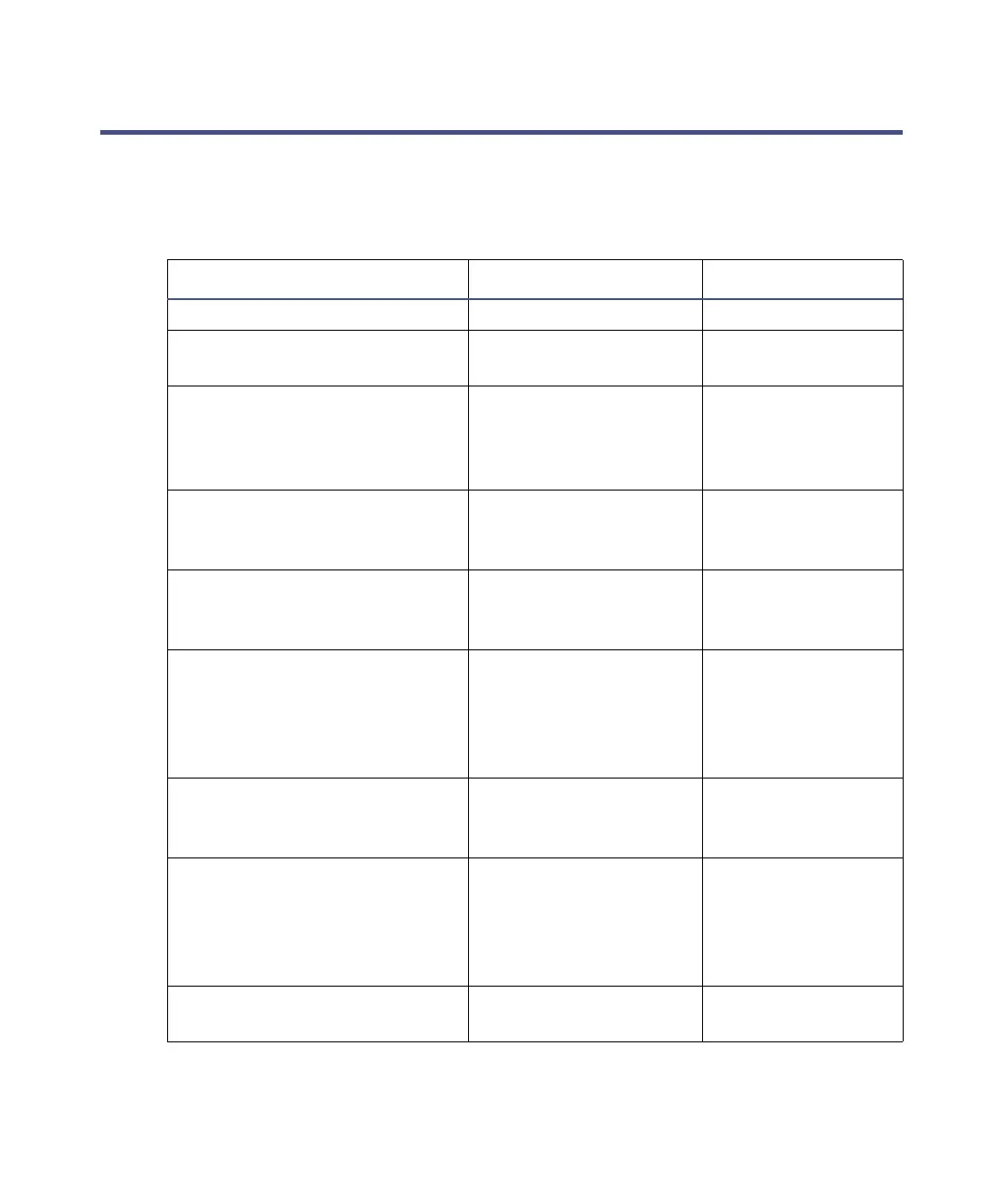

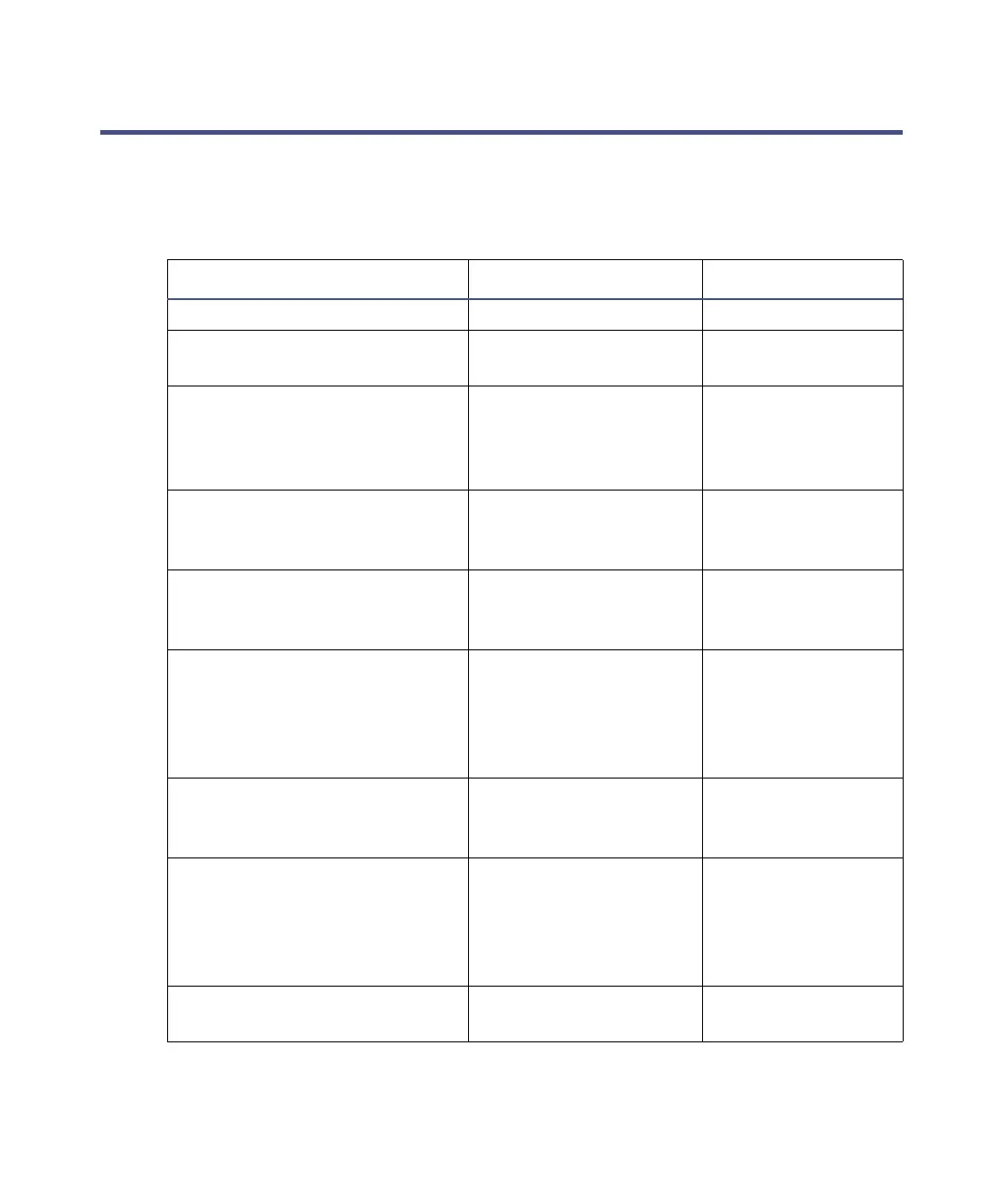

Maintenance schedule 5-3

Maintenance schedule

The following table lists periodic maintenance schedules that ensure optimum

instrument performance.

Maintenance schedule

Procedure Frequency For information...

Clean the instrument case. As required. See page 5-18.

Empty the nitrogen exhaust

trap bottle.

Check daily, empty as

required.

See page 5-19.

Replace the oil-free (scroll)

pump’s seals.

Annually. See Edwards

document XDS35i

Instruction Manual

A730-01-880.

Clean the source components. When sensitivity

decreases to

unacceptable levels.

See page 5-21.

Replace the ESI probe tip. When sensitivity

decreases to

unacceptable levels.

See page 5-55.

Replace the ESI probe

capillary.

When sensitivity

decreases to

unacceptable levels or

sample flow is

inconsistent.

See page 5-59.

Clean the APCI probe tip.

(Options using the APCI

probe only.)

When sensitivity

decreases to

unacceptable levels.

See page 5-67.

Replace the APCI probe

capillary.

When sensitivity

decreases to

unacceptable levels or

sample flow is

inconsistent.

See page 5-68.

Replace the LockSpray probe

capillary.

Annually. See page 5-74.

Loading...

Loading...