108

DETAILED PARAMETER DESCRIPTION

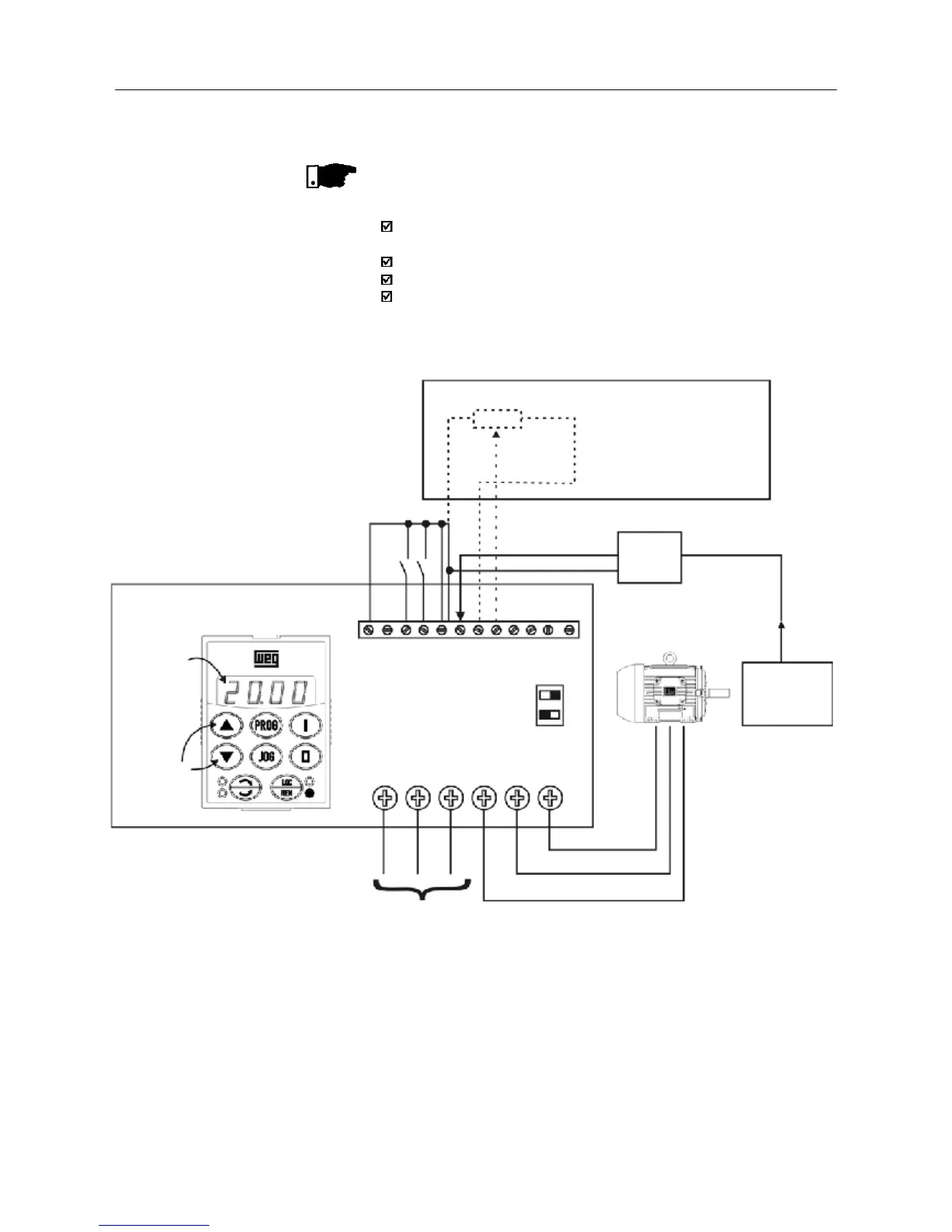

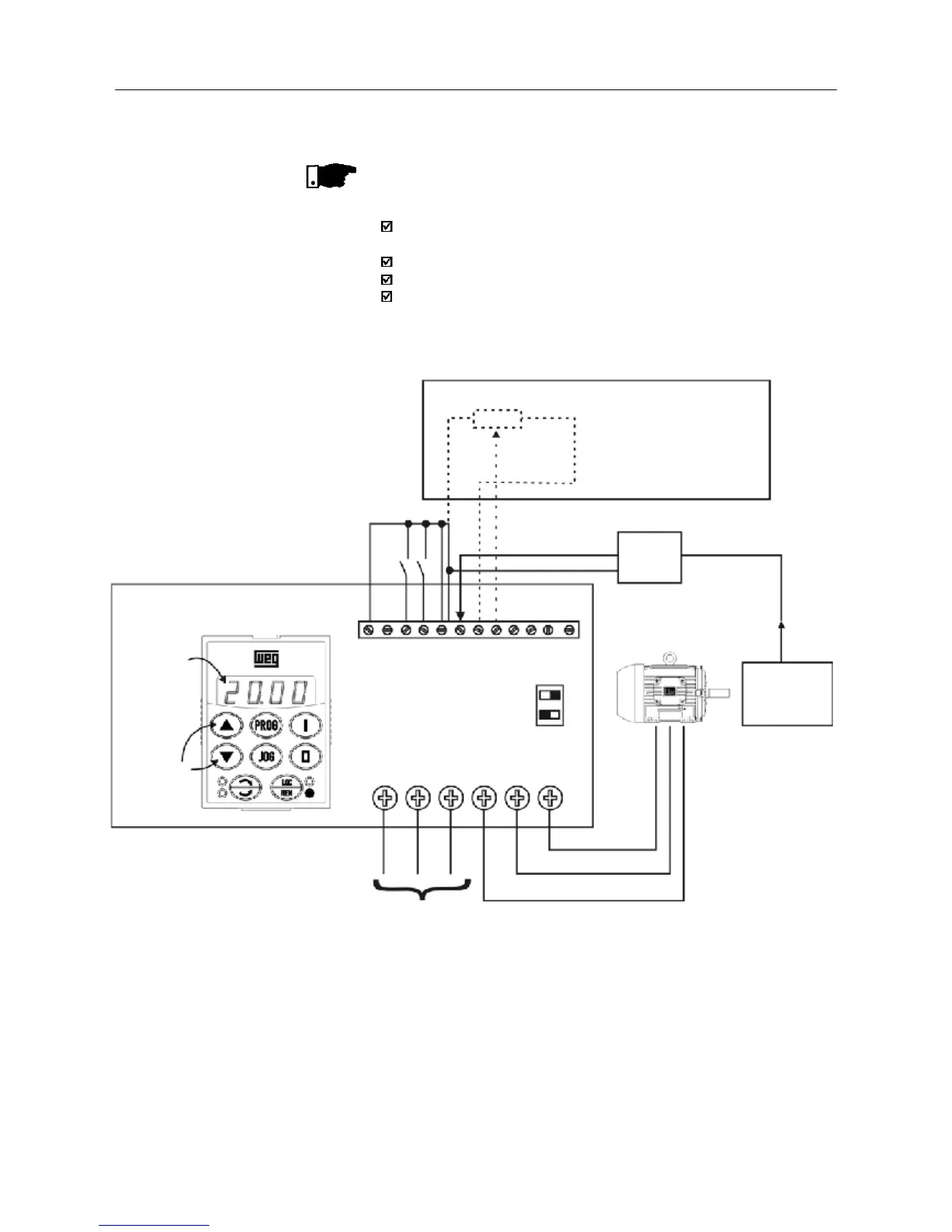

Figure 6.26 - Application example of an inverter with PID regulator

NOTE!

The inverter setting must be correct in order to obtain a good performance

of the PID regualtor. Ensure the following settings:

torque boosts (P136 and P137) and slip compensation (P138) in the

V/F control (P202=0 ou 1);

ensure that the self-tuning has been run, if in vector control (P202=2);

acceleration and deceleration ramps (P100...P103);

current limitation (P169).

CFW-08

P040

Content

Setpoint can

be changed

by the keys

X1

1 2 3 4 5 6

Line

1

2

S1

off on

123456789101112

DI1 - Gen.enable

DI3 - Manual/Auto

DI4 - Star/Stop

AI1 - Feedback

Pressure

Transducer

4-20mA

0-25 bar

0-100%

(0-25bar)

5k

≥

Setpoint via AI2 (available

with CFW-08 Plus only)

P222=2

P238=1.00

P239=0

P240=0.00

Remote mode operation (P220=1)

Setpoint via keypad.

Inverter Parametrization:

P220=1 P520=1.000

P222=0 P521=1.000

P234=1.00 P522=0.000

P235=1 P525=0

P238=0.00 P526=0.1s

P203=1 P527=0

P205=6 P528=25

Process

Loading...

Loading...