CYLINDER

BLOCK

SERVICE

9. Install the oil seal into the crankshaft rear oil seal case.

Install the seal case to the cylinder block. Remember to

install the

gasket. Turn the crankshaft one complete revo-

lution

to

ensure there is

no

unwanted binding.

10. Install the back plate.

11. Install the flywheel. The bolts should be tightened to the

specified torque.

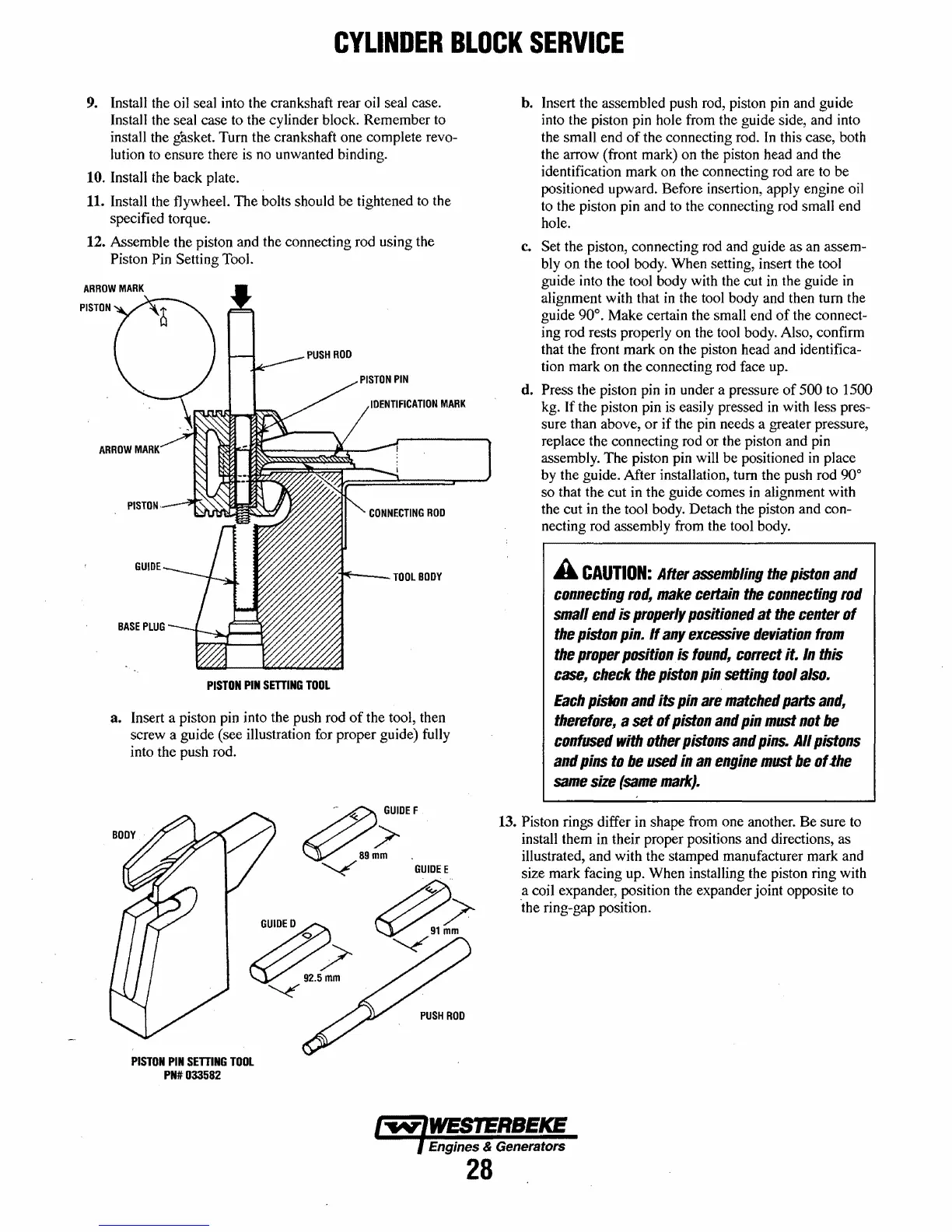

12. Assemble the piston and the connecting rod using the

Piston Pin Setting Tool.

CONNECTING

ROO

/////';I'E'-

__

TOOL

BOOY

PISTON

PIN

SETTING

TOOL

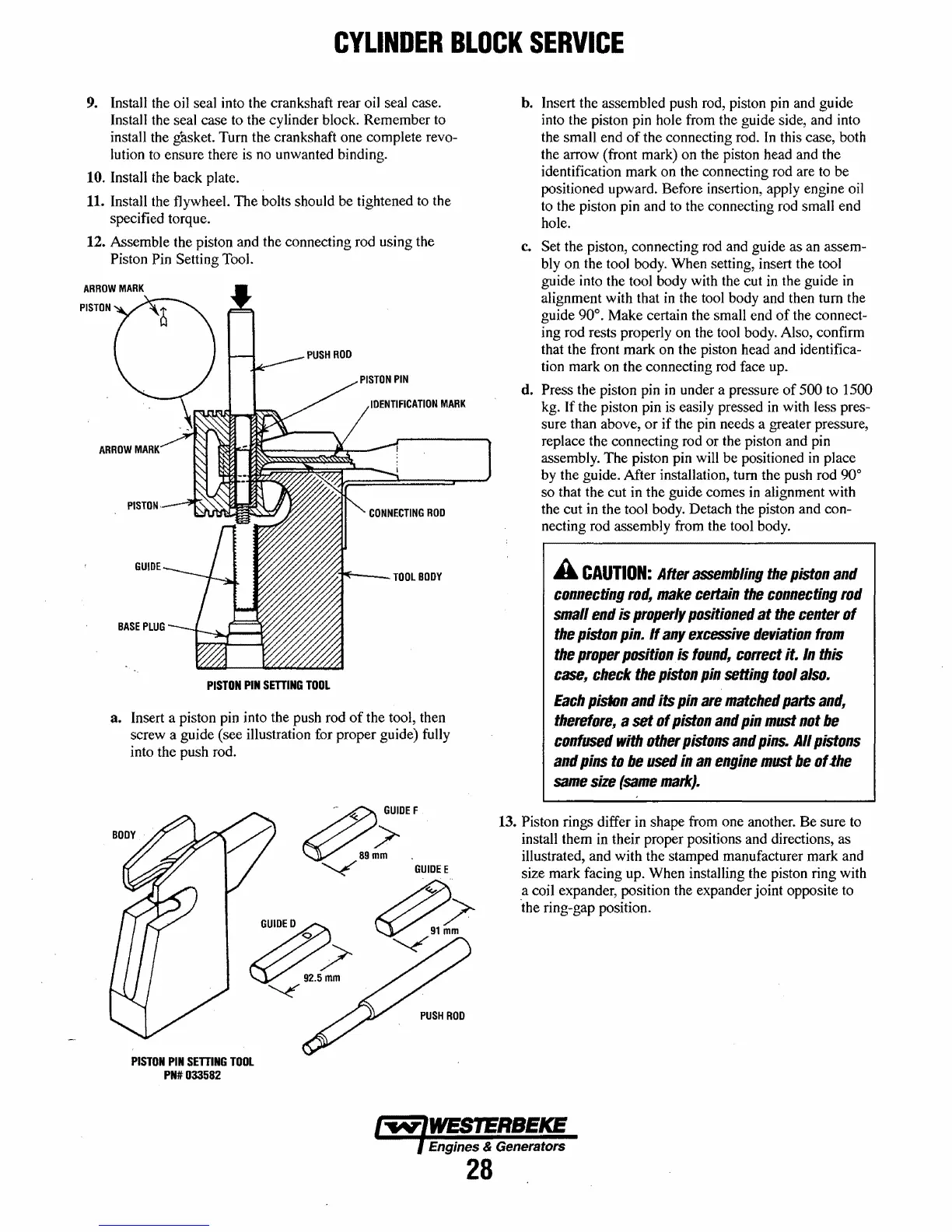

3.

Insert a piston pin into the push rod

of

the tool, then

screw a guide (see illustration for proper guide) fully

into the push rod.

/1);0"

~9~m

~

GUIDEE

G~;>

~.~m

~

~~

~

PISTON

PIN

SETTING

TOOL

PN#033582

PUSH

ROD

h. Insert the assembled push rod, piston pin and guide

into the piston pin hole from the guide side, and into

the small end

of

the connecting rod.

In

this case, both

the arrow (front mark) on the piston head and the

identification mark on the connecting rod are

to

be

positioned upward. Before insertion, apply engine oil

to

the piston pin and to the connecting rod small end

hole.

c.

Set the piston, connecting rod and guide as an assem-

bly on the tool body. When setting, insert the tool

guide into the tool body with the cut

in

the guide

in

alignment with that

in

the tool body and then turn the

guide

90°. Make certain the small end

of

the connect-

ing rod rests properly on the tool body. Also, confirm

that the front mark on the piston head and identifica-

tion mark on the connecting rod face up.

d.

Press the piston pin

in

under a pressure

of

500 to 1500

kg. If the piston pin is easily pressed

in

with less pres-

sure than above,

or

if the pin needs a greater pressure,

replace the connecting rod or the piston and pin

assembly. The piston pin will be positioned

in

place

by the guide. After installation, tum the push rod

90°

so that the cut in the guide comes in alignment with

the cut in the tool body. Detach the piston and con-

necting rod assembly from the tool body.

A

CAUTION:

After

assembling

the

piston

and

connecting

rod,

make

certain

the

connecting

rod

small

end

is

properly

positioned

at

the

center

01

the

piston

pin.

II

any

excessive

deviation

Irom

the

proper

position

is

lound!l

correct

it.

In

this

case,

check

the

piston

pin

setting

tool

also.

Each

pislon

and

its

pin

are

matched

parts

and!l

therefore,

a set

01

piston

and

pin

must

not

be

confused

with

other

pistons

and

pins.

All

pistons

and

pins

to

be

used

in

an

engine

must

be

of

.the

same

size

(same

mark).

13. Piston rings differ in shape from one another. Be sure to

install them

in

their proper positions and directions, as

illustrated, and with the stamped manufacturer mark and

size mark facing up. When installing the piston ring with

a coil expander, position the expander joint opposite

to

'the ring-gap position.

Engines & Generators

28

Loading...

Loading...