PROCEDURE

1 Operate the turning gear to move the piston to BDC.

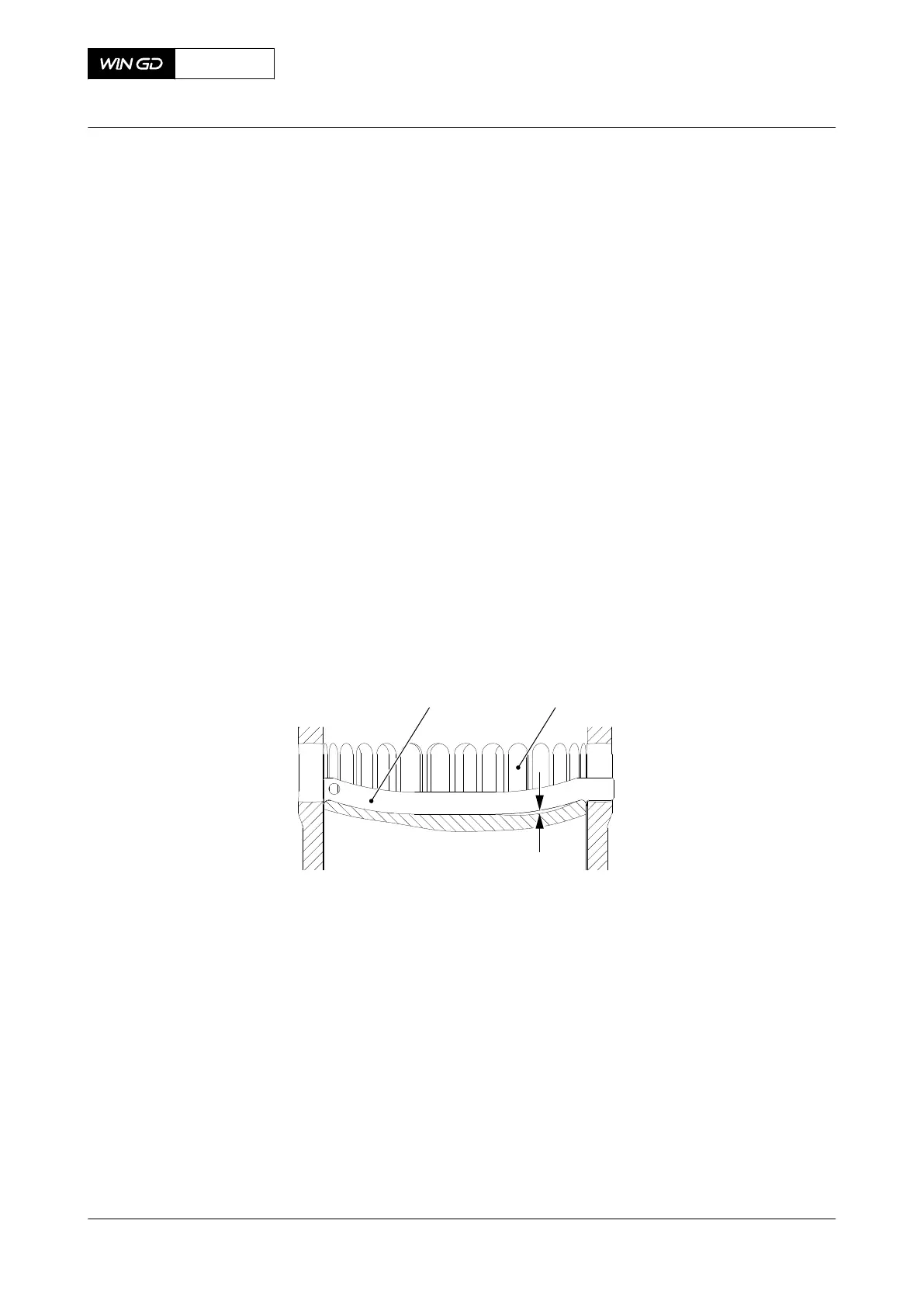

2 Look through the scavenge ports (002) for burn scars on the piston head (001, Figure

8-66).

3 Put the template (001) through the related scavenge port (002).

4 Use the feeler gauge to measure the depth of the burn scar(s).

NOTE: You can also use a depth gauge to measure the depth of the burn scar(s).

5 Remove the template (001).

6 If there are more burn scars, do Step 3 to Step 5 again through an other scavenge port.

7 If the burn scars are less than 10 mm, do as follows:

7.1 Use an applicable tool to grind the burn scars.

7.2 Use an emery cloth to make sharp edges smooth.

8 If the burn scars are 10 mm or more, do as follows:

8.1 Remove the piston, refer to section 8.7.3 Piston - remove.

8.2 Disassemble the piston, refer to section 8.7.4 Piston - disassemble.

8.3 Use surface welding to repair the piston head to its original thickness.

8.4 Assemble the piston, refer to section 8.7.6 Piston - assemble.

8.5 Install the piston, refer to section 8.7.7 Piston - install.

Fig 8-66 Top surface - dimensions check

9 Find the cause of the burn scars and repair the fault.

X72DF

AA00-3403-00AAA-360A-A

Maintenance Manual Piston (installed) - do checks of the surface and clearances

Winterthur Gas & Diesel Ltd.

- 473 - Issue 002 2020-10

Loading...

Loading...