3.2Setting User Constants According to Host Controller

75

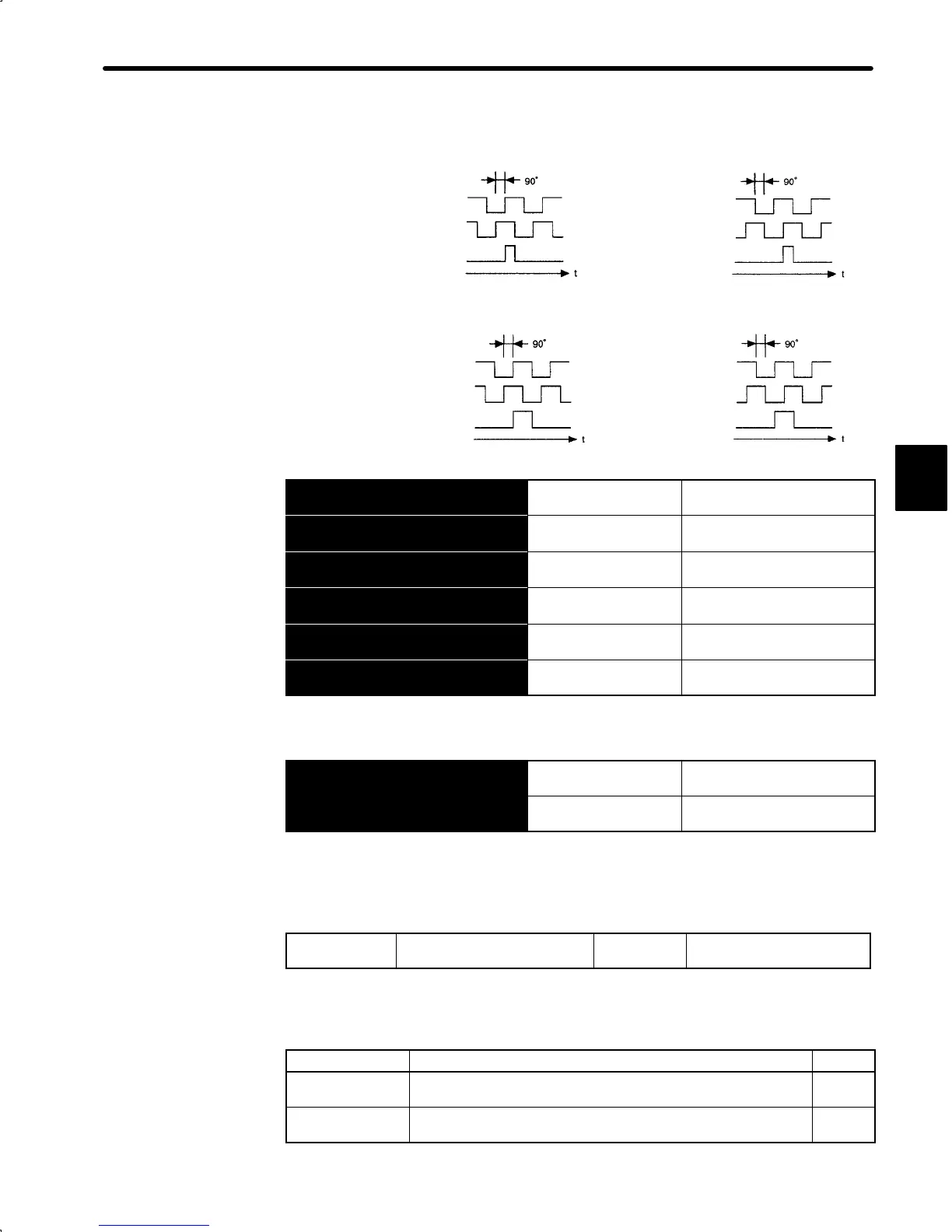

Output Phase Form

Forward rotation Reverse rotation

Incremental Encoder

Phase A

Phase B

Phase C

Phase A

Phase B

Phase C

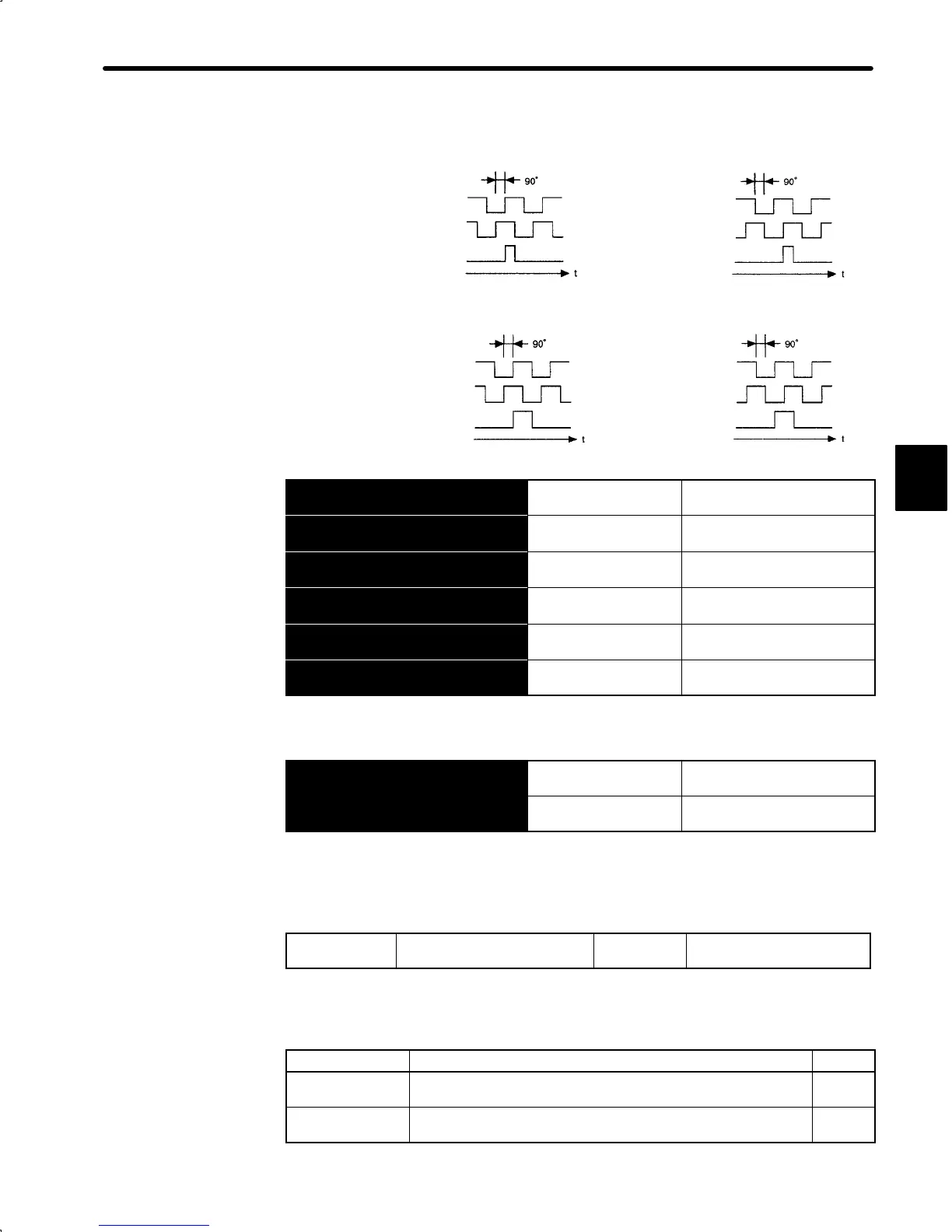

Absolute Encoder

Forward rotation Reverse rotation

Phase A

Phase B

Phase C

Phase A

Phase B

Phase C

→ Input SEN 1CN-5

SEN Signal Input For Speed/Torque Control

Only

→ Input 0SEN 1CN-6

SEN Signal Input For Speed/Torque Control

Only

Output → PSO 1CN-26

Encoder Output

Phase-S

For Speed/Torque Control

and Position Control

Output →

£

PSO 1CN-27

Encoder Output

Phase-S

For Speed/Torque Control

and Position Control

→ Input BAT 1CN-28

Battery (+) For Speed/Torque Control

and Position Control

→ Input BAT0 1CN-29

Battery (−) For Speed/Torque Control

and Position Control

Use these signals (SEN to BAT0) for absolute encoders. For details, refer to 3.8.5 Using

an Absolute Encoder.

Output → SG 1CN-19

Signal Ground for

Encoder Output

For Speed/Torque Control

and Position Control

Output → FG 1CN-36

Frame Ground For Speed/Torque Control

and Position Control

SG: Connect to 0 V on the host controller.

FG: Connect to the cable shielded wire.

3) Use the following memory switch to specify the type of the encoder to be used.

Cn-01 Bit E

Encoder Type Selection Factory

Setting: 0

For Speed/Torque Control

and Position Control

Sets the encoder type according to the servomotor type as shown in the table.

After changing the memory switch setting, always turn the power OFF, then ON.

Motor Type Number of Encoder Pulses Per Revolution (P/R) Setting

SGM-jjj31j

Incremental encoder:

2,048 pulses per revolution

0

SGM-jjjW1j

Absolute encoder:

1,024 pulses per revolution

1

3

Loading...

Loading...