5.4.3 Electronic Gear

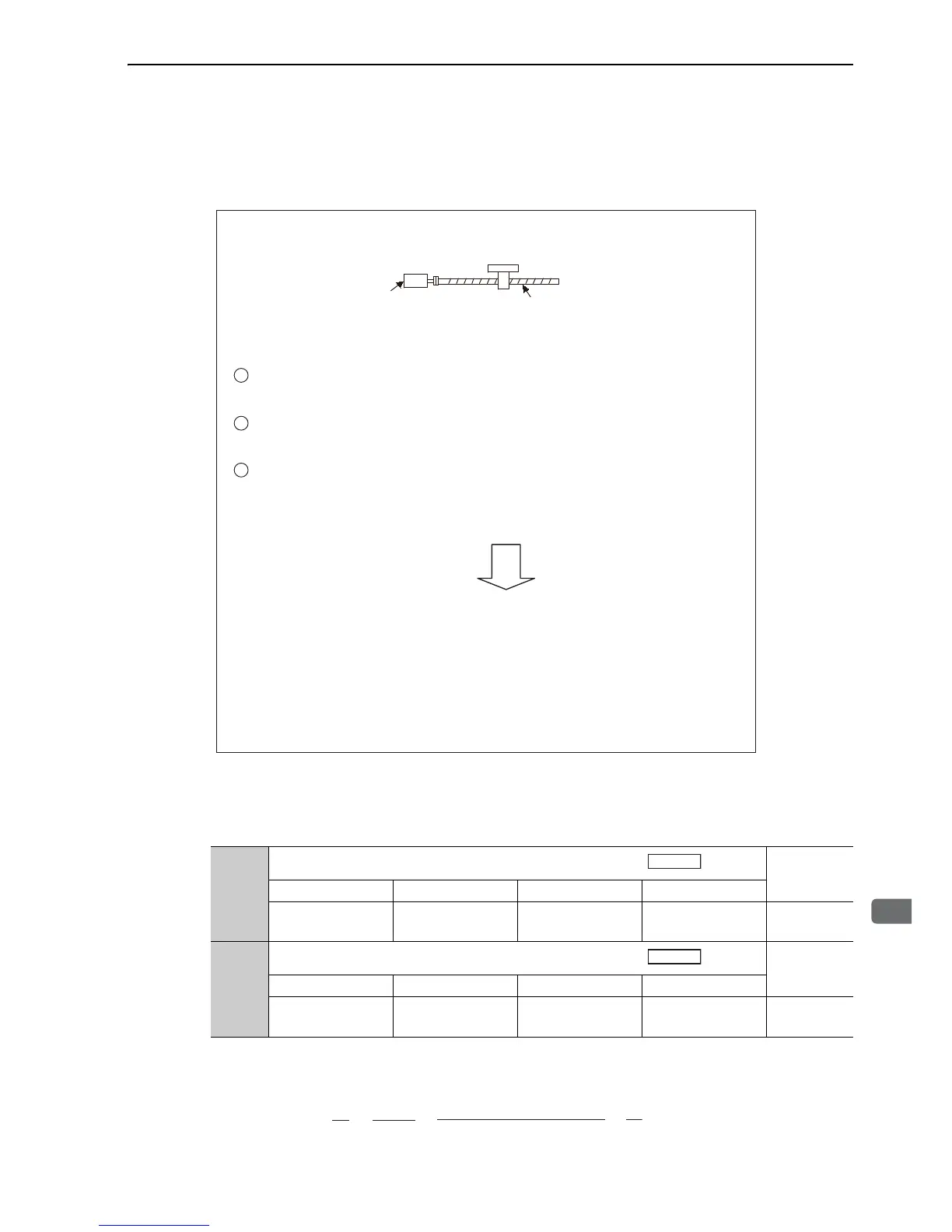

The electronic gear enables the workpiece travel distance per input reference pulse from the host controller to

be set to any value. The minimum position data moving a load is called a reference unit.

(1) Electric Gear Ratio

Set the electric gear ratio using Pn20E and Pn210.

If the gear ratio of the motor and the load shaft is given as n/m where m is the rotation of the motor and n is the

rotation of the load shaft,

To move a workpiece 10 mm:

When the Electronic Gear is Not Used:

Calculate the revolutions.

1 revolution is 6 mm. Therefore, 10 ÷ 6 = 1.6666 revolutions.

Calculate the required reference pulses.

1048576 pulses is 1 revolution. Therefore, 1.6666 × 1048576 = 1746928 pulses.

Input 1746928 pulses as reference pulses.

Reference pulses must be calculated per reference. → complicated

When the Electronic Gear is Used:

The reference unit is 1μm. Therefore, to move the workpiece 10 mm (10000μm),

1 pulse = 1μm, so 10000 ÷ 1 = 10000 pulses.

Input 10000 pulses as reference pulses.

Calculation of reference pulses per reference is not required. → simplified

Ball screw pitch: 6 mm

Workpiece

Encoder resolution (20 bit) 1048576

1

2

3

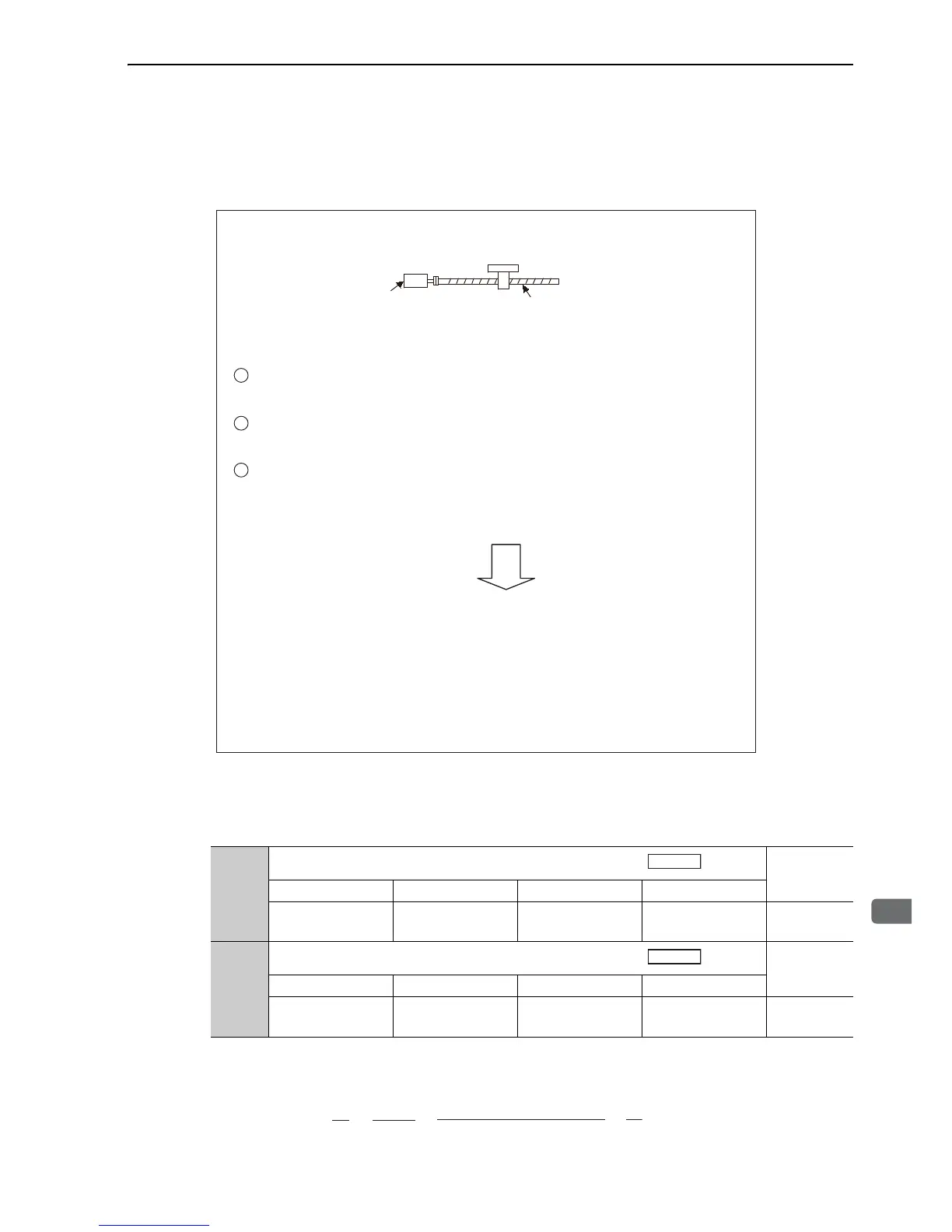

Pn20E

Electronic Gear Ratio (Numerator)

Classification

Setting Range Setting Unit Factory Setting When Enabled

1 to 1073741824

(2

30

)

1 4 After restart Setup

Pn210

Electronic Gear Ratio (Denominator)

Classification

Setting Range Setting Unit Factory Setting When Enabled

1 to 1073741824

(2

30

)

1 1 After restart Setup

Loading...

Loading...