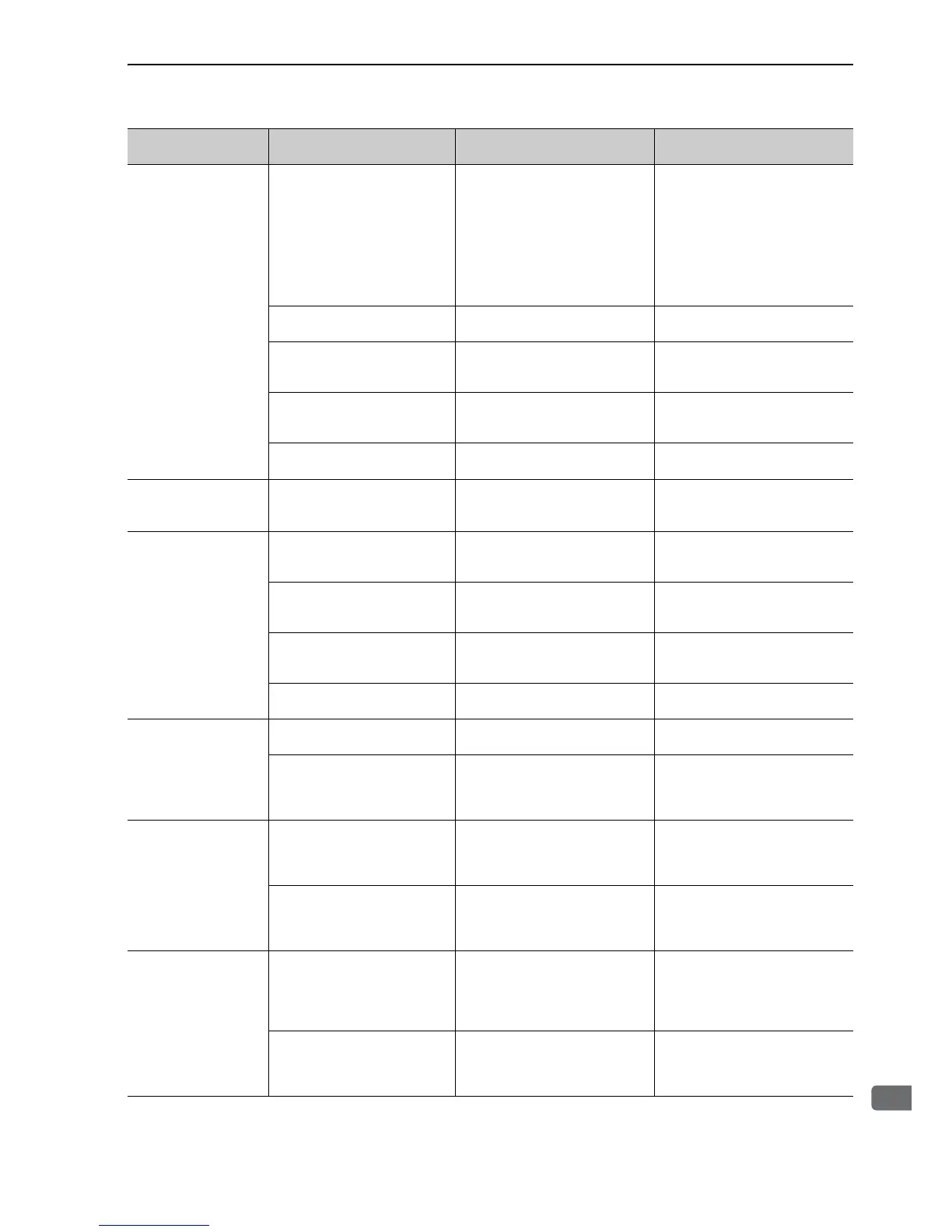

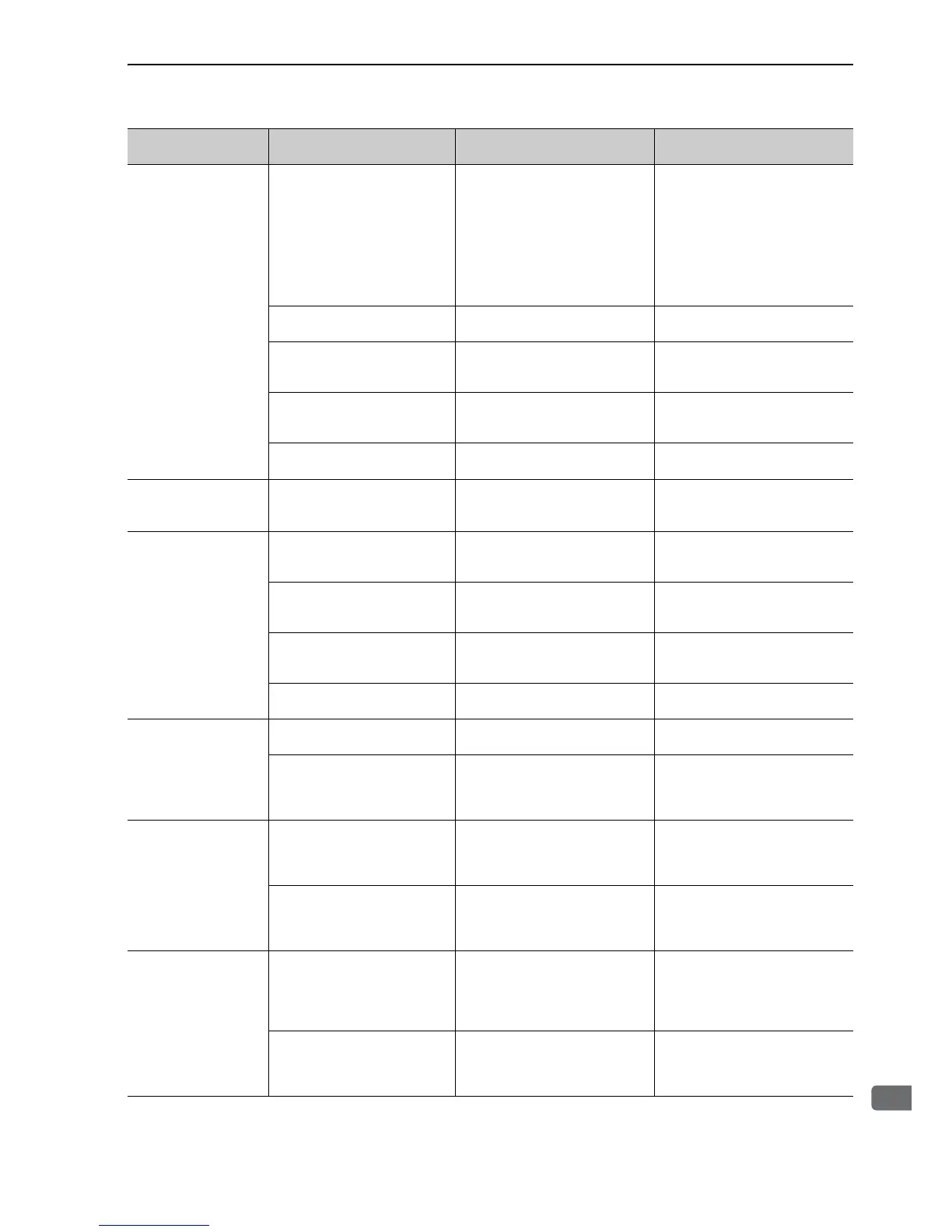

A.410:

Undervoltage

(Detected in the SER-

VOPACK main circuit

power supply section.)

• For 100 VAC SERVOPACKs:

The power supply voltage is 49

V or less.

• For 200 VAC SERVOPACKs:

The power supply voltage is

120 V or less.

• For 400 VAC SERVOPACKs:

The power supply voltage is

240 V or less.

Measure the power supply voltage.

Set the power supply voltage within

the specified range.

The power supply voltage

dropped during operation.

Measure the power supply voltage. Increase the power supply capacity.

Occurrence of instantaneous

power interruption.

Measure the power supply voltage.

When the instantaneous power cut

hold time Pn509 is set, decrease the

setting.

The SERVOPACK fuse is blown

out.

−

Repair or replace the SERVO-

PACK, connect an AC/DC reactor,

and run the SERVOPACK.

A SERVOPACK fault occurred. −

The SERVOPACK may be faulty.

Replace the SERVOPACK.

A.450:

Main-Circuit

Capacitor Overvoltage

A SERVOPACK fault occurred. − Replace the SERVOPACK.

A.510:

Overspeed

(The servomotor speed

exceeds the maximum.)

The order of phases U, V, and W

in the servomotor wiring is incor-

rect.

Check the servomotor wiring.

Confirm that the servomotor is cor-

rectly wired.

A reference value exceeding the

overspeed detection level was

input.

Check the input value.

Reduce the reference value or adjust

the gain.

The motor speed exceeded the

maximum.

Check the servomotor speed wave-

form.

Reduce the speed reference input

gain, adjust the servo gain, or recon-

sider the operation conditions.

A SERVOPACK fault occurred. −

The SERVOPACK may be faulty.

Replace the SERVOPACK.

A.511:

Overspeed of Encoder

Output Pulse Rate

The encoder output pulse output

frequency exceeded the limit.

Check the encoder output pulse out-

put setting.

Decrease the setting of the encoder

output pulse (Pn212).

The encoder output pulse output

frequency exceeded the limit

because the servomotor speed

was too high.

Check the encoder output pulse out-

put setting and servomotor speed.

Decrease the servomotor speed.

A.520:

Vibration Alarm

Abnormal vibration was detected

at the servomotor rotation speed.

Check for abnormal noise from the

servomotor, and check the speed

and torque waveform during opera-

tion.

Reduce the servomotor speed or

reduce the speed loop gain (Pn100).

The moment of inertia ratio

(Pn103) value is greater than the

actual valu

e or is greatly

changed.

Check the moment of inertia ratio.

Set the moment of inertia ratio

(Pn103) to an appropriate value.

A.521:

Autotuning Alarm

(Vibration was detected

while executing the

advanced autotuning,

one-parameter tuning,

EasyFFT, or tuning-less

function.)

The servomotor vibrated consid-

erably while performing tuning-

less function (factory setting).

Check the servomotor speed wave-

form.

Reduce the load so that the moment

of inertia ratio falls within the

allowable value, or raise the tuning

level or reduce the gain level using

the tuning-less function (Fn200).

The servomotor vibrated consid-

erably during advanced autotun-

ing, one-parameter tuning, or

EasyFFT.

Check the servomotor speed wave-

form.

Check the operation procedure of

corresponding function and take a

corrective action.

Alarm:

Alarm Name

Cause Investigative Actions Corrective Actions

Loading...

Loading...