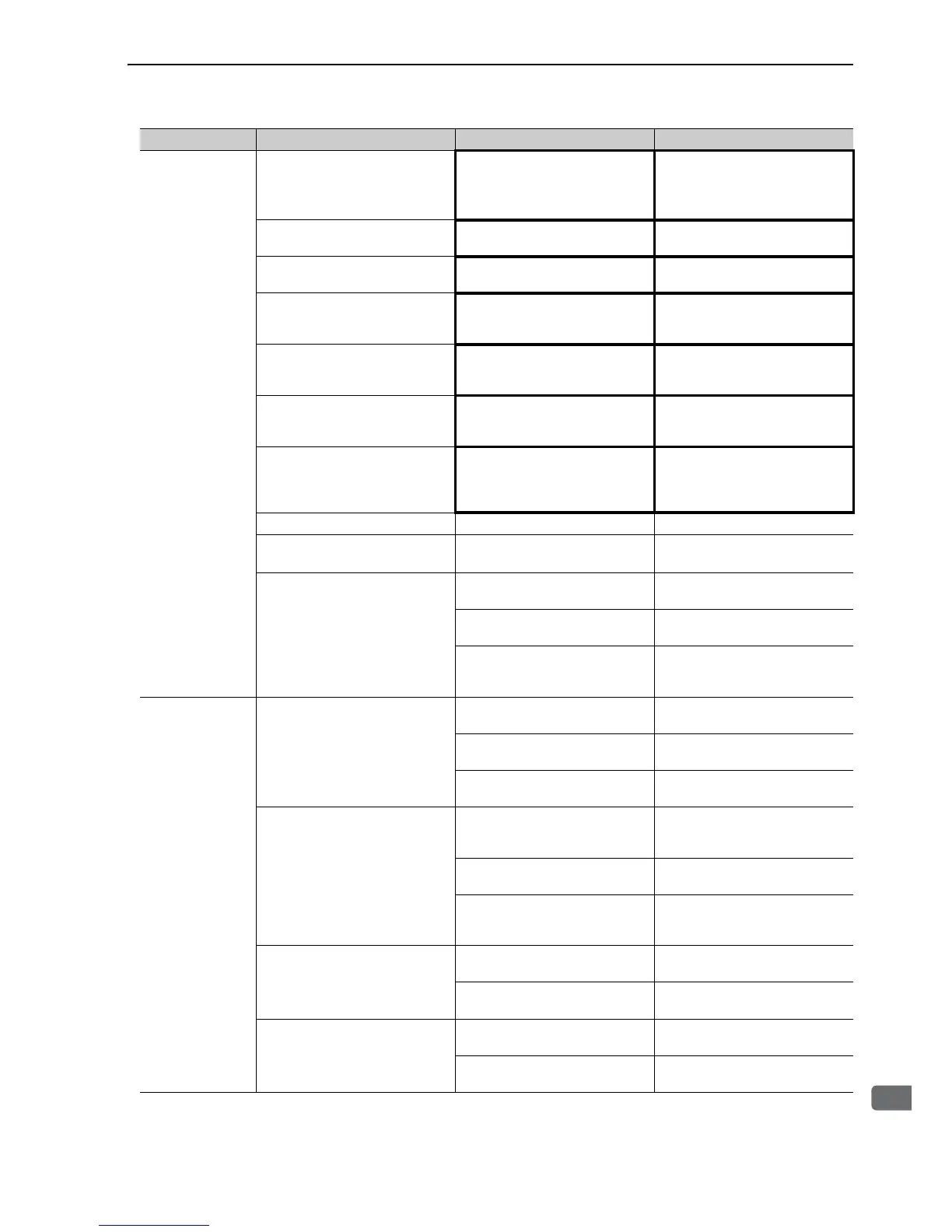

Absolute Encoder

Position

Difference Error

(The position

saved in the host

controller when

the power was

turned OFF is

different from the

position when the

power was next

turned ON.)

Noise interference due to improper

encoder cable specifications

The encoder cable must be tinned

annealed copper twisted-pair or

shielded twisted-pair cables with a

core of 0.12 mm

2

min.

Use encoder cable with the speci-

fied specifications.

Noise interference due to length of

encoder cable.

Check the encoder cable length.

The encoder cable length must be

no more than 20 m.

Noise interference due to damaged

encoder cable

Check if the encoder cable is bent or

if its sheath is damaged.

Replace the encoder cable and cor-

rect the encoder cable layout.

Excessive noise interference at the

encoder cable

Check if the encoder cable is bun-

dled with a high-current line or near

high-current line.

Change the encoder cable layout so

that no surge is applied.

FG potential varies because of

influence of machines such as weld-

ers at the servomotor.

Check if the machines are correctly

grounded.

Ground machines correctly, and

prevent diversion to the FG at the

PG side.

SERVOPACK pulse counting error

due to noise interference

Check if there is noise interference

on the input/output signal line from

the encoder.

Take measures against noise in the

encoder wiring.

Excessive vibration and shock to

the encoder

Check if vibration from the machine

occurred or servomotor installation

is incorrect (mounting surface accu-

racy, fixing, alignment, etc.).

Reduce vibration from the machine,

or secure the servomotor installa-

tion.

An encoder fault occurred. − Replace the servomotor.

A SERVOPACK fault occurred.

(The pulse count does not change.)

− Replace the SERVOPACK.

Host controller multi-turn data read-

ing error

Check the error detection at the host

controller.

Correct the error detection section

of the host controller.

Check if the host controller is exe-

cuting data parity checks.

Execute a multi-turn data parity

check.

Check noise in the input/output sig-

nal line between the SERVOPACK

and the host controller.

Take measures against noise, and

again execute a multiturn data par-

ity check.

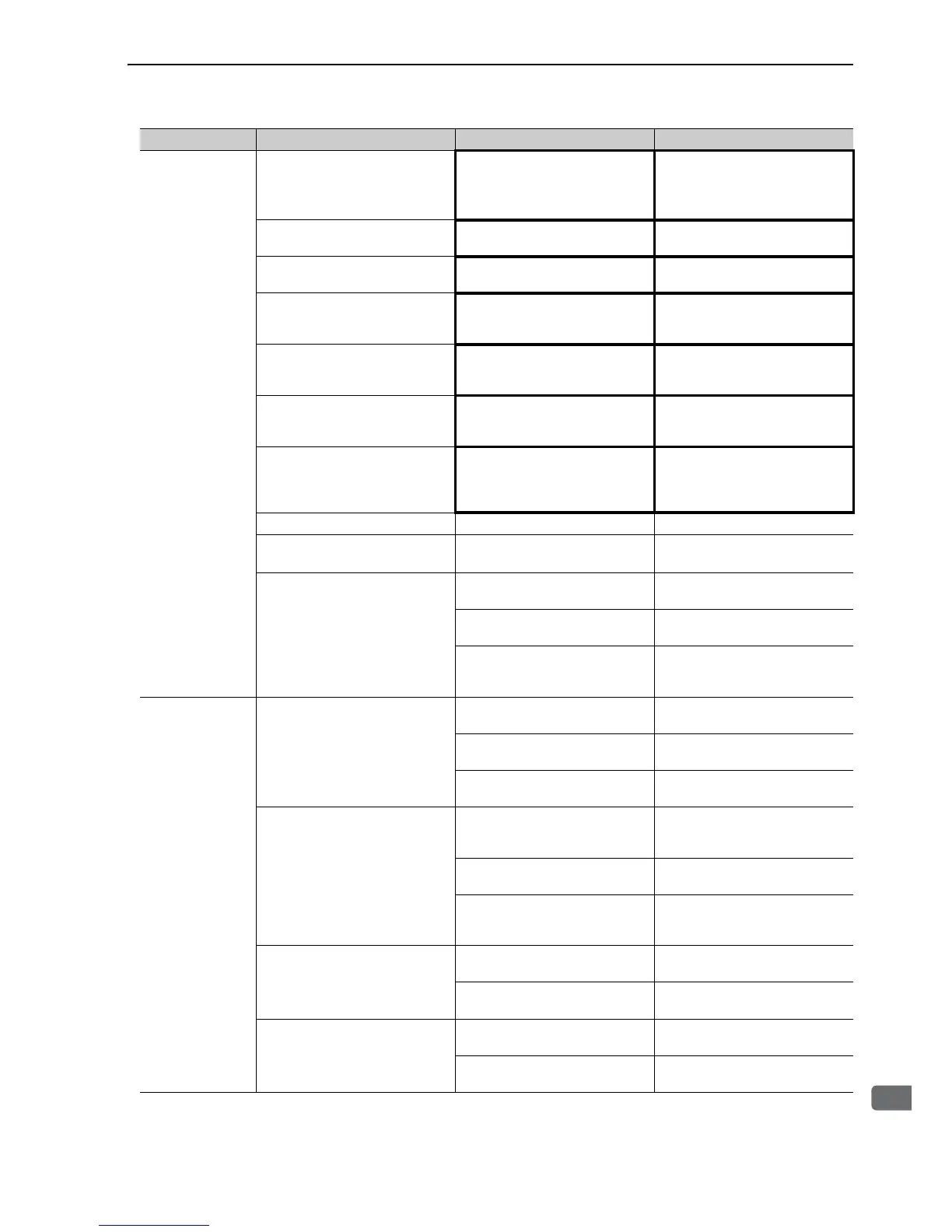

Overtravel (OT)

Forward or reverse run prohibited

signal is input.

Check the external power supply

(+24 V) voltage for the input signal.

Correct the external power supply

(+24 V) voltage.

Check if the overtravel limit switch

operates properly.

Correct the overtravel limit switch.

Check if the overtravel limit switch

is wired correctly.

Correct the overtravel limit switch

wiring.

Forward or reverse run prohibited

signal malfunctioning.

Check the fluctuation of the input

signal external power supply (+24

V) voltage.

Stabilize the external power supply

(+24 V) voltage.

Check if the overtravel limit switch

operates correctly.

Stabilize the operation of the over-

travel limit switch.

Check if the overtravel limit switch

wiring is correct. (check for dam-

aged cables or loose screws.)

Correct the overtravel limit switch

wiring.

Incorrect forward or reverse run

prohibited signal (P-OT/N-OT)

allocation (parameters Pn50A.3,

Pn50B.0)

Check if the P-OT signal is allo-

cated in Pn50A.3.

If anot

her signal is allocated in

Pn50A.3, select P-OT.

Check if the N-OT signal is allo-

cated in Pn50B.0.

If another signal is allocated in

Pn50B.0, select N-OT.

Incorrect servomotor stop method

selection

Check Pn001.0 and Pn001.1 when

the servomotor power is OFF.

Select a servo mode stop method

other than "coast to stop."

Check Pn001.0 and Pn001.1 when

in torque control.

Select a servo mode stop method

other than "coast to stop."

Problem Probable Cause Investigative Actions Corrective Actions

Loading...

Loading...