933D Systems, Inc.

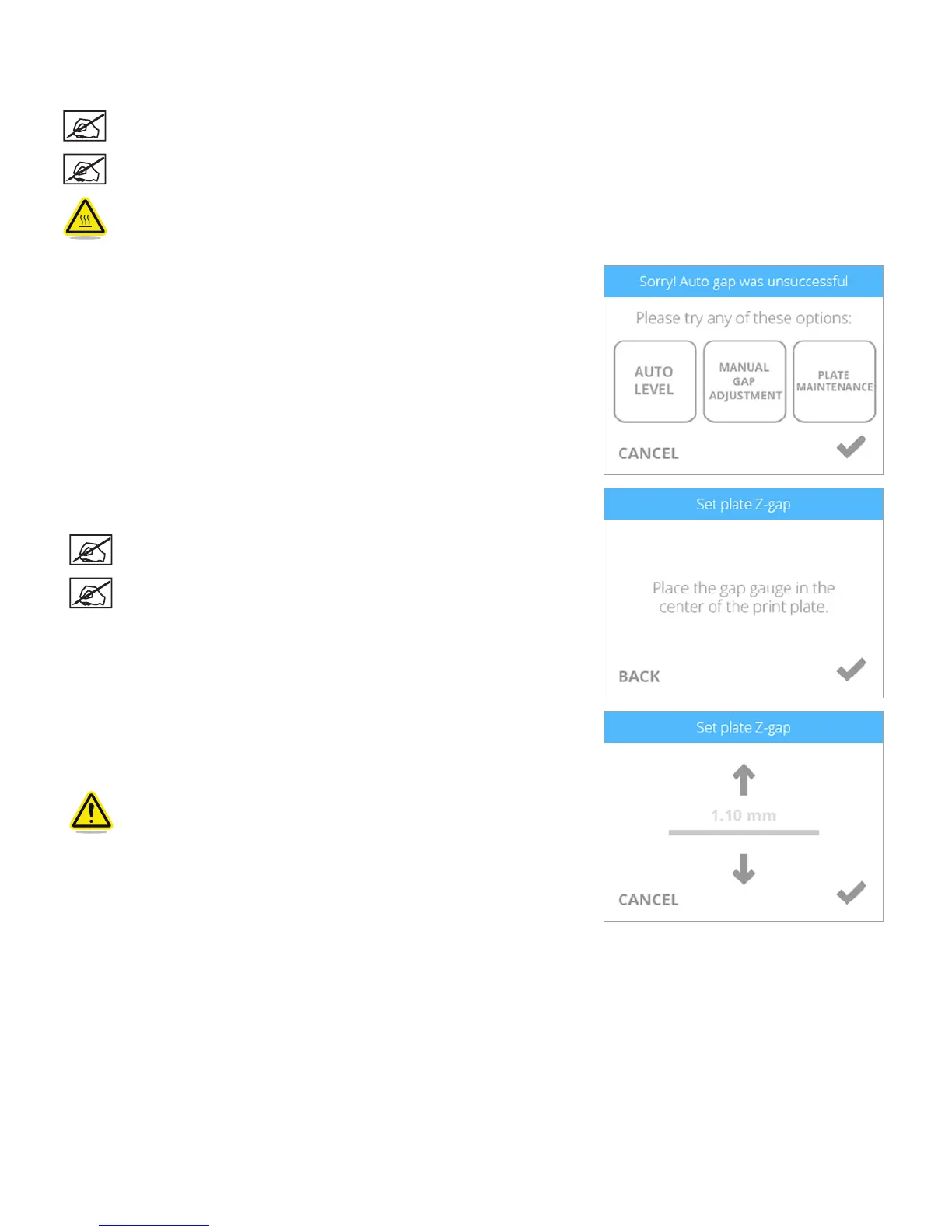

Manual Gap Adjustment

If Auto Gap is unsuccessful, you may perform a manual gap adjustment to ensure the rst layer of the part prints properly.

NOTE: The print pad must be clean and free from glue and print material.

NOTE: Ensure the print jet nozzles are clean and free from print material. This can usually be accomplished by

pulling out the print material with your ngers.

Caution: Ensure the print jet nozzles are at room temperature before attempting to clean them.

1. Select MANUAL GAP ADJUSTMENT.

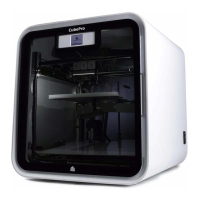

2. Place the gap gauge on top of the print pad under the left print jet. Select the

checkmark to continue.

NOTE: Ensure the left cartridge is installed before performing this

procedure.

NOTE: The Gap Gauge is a thin polyester strip approximately 8.5”

(216 mm) long and 1.5” (38 mm) wide.

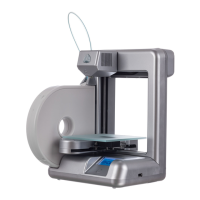

3. Gently slide the gap gauge back and forth between the print pad and the left

print jet. Using the arrows, raise or lower the print pad until you feel a slight

resistance on the gauge. Select the checkmark when you feel the proper

resistance.

Caution: Exercise caution to prevent the print jet from pressing into

the print pad. Once you feel a slight resistance in the Gap Gauge

as it moves between the print pad and the left print jet, the gap is

correct.

Loading...

Loading...