152 Program features

Process controller PID1

PID1 has two separate sets of parameters (40 PROCESS PID SET 1, 41 PROCESS

PID SET 2). Selection between parameter sets 1 and 2 is defined by a parameter.

In most cases when there is only one transducer signal wired to the drive, only

parameter set 1 is needed. Two different parameter sets (1 and 2) are used, eg, when

the load of the motor changes considerably in time.

External/Trim controller PID2

PID2 (42 EXT / TRIM PID) can be used in two different ways:

• External controller: Instead of using additional PID controller hardware, the user

can connect PID2 output through drive analog output or fieldbus controller to

control a field instrument like a damper or a valve.

• Trim controller: PID2 can be used to trim or fine tune the reference of the drive.

See section Reference trimming on page 130.

Block diagrams

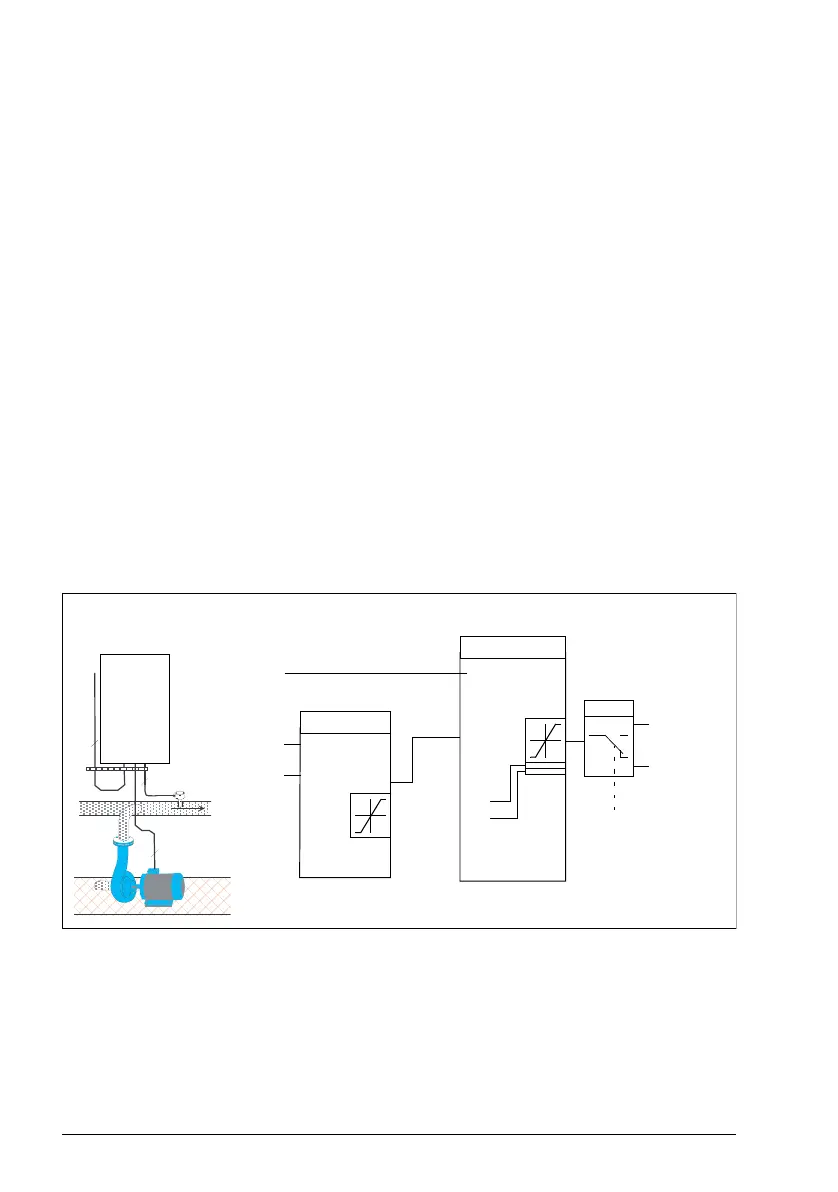

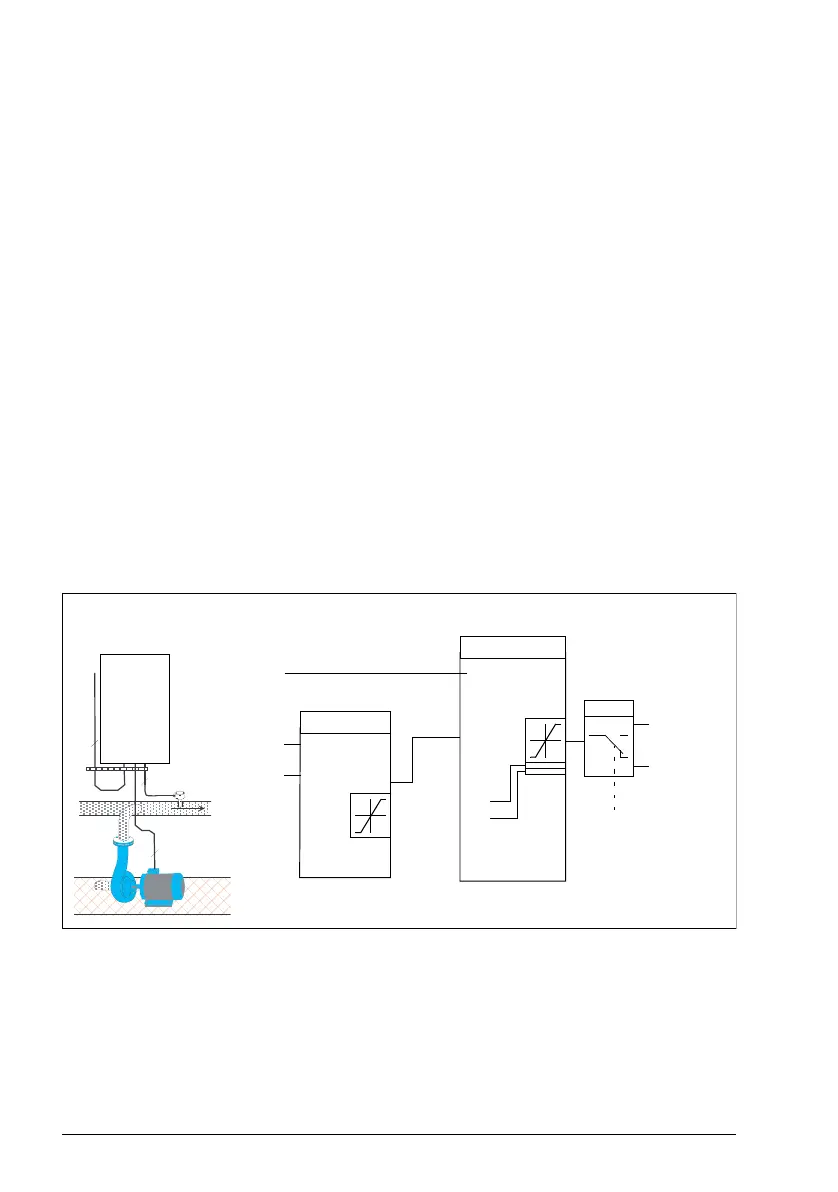

The figure below shows an application example: The controller adjusts the speed of a

pressure boost pump according to the measured pressure and the set pressure

reference.

ref

k

ti

td

i

dFiltT

errVInv

oh1

ol1

Speed

reference

%ref = 4010

…

.

.

.

AC T PA R FU NC DR IVE

E NT ER

LO C

RE M

RE SET

RE F

A C S 6 0 0

0 . . . 1 0 b a r

4 . . . 2 0 m A

3

3

2

PID control block diagramExample:

Pressure boost pump

4001

4002

4003

4004

4005

PIDmin

PIDmax

4014

4021

AI1

AI2

IMOT

%ref

Actual values

PID

Switch

9904 = 0

Frequency

reference

Loading...

Loading...