88 Program features

mentioned above are 1:1. The ratios can only be changed with the drive stopped;

new settings require validation by 91.10 Encoder parameter refresh.

Position counter

The control program contains a position counter feature that can be used to indicate

the position of the load. The output of the counter function, parameter 90.07 Load

position scaled int, indicates the scaled number of revolutions read from the selected

source (see section Load and motor feedback on page 87).

The relation between revolutions of the motor shaft and the translatory movement of

the load (in any given unit of distance) is defined by parameters 90.63 Feed constant

numerator and 90.64 Feed constant denominator. This gear function can be changed

without the need of a parameter refresh or position counter reinitialization – however,

the counter output is only updated after new position input data is received.

For detailed parameter connections of the load feedback function, see the block

diagram on page 648.

The position counter is initialized by setting a known physical position of the load into

the control program. The initial position (for example, the home/zero position, or the

distance from it) can be entered manually in a parameter (90.58 Pos counter init

value int), or taken from another parameter. This position is set as the value of the

position counter (90.07 Load position scaled int) when the source selected by 90.67

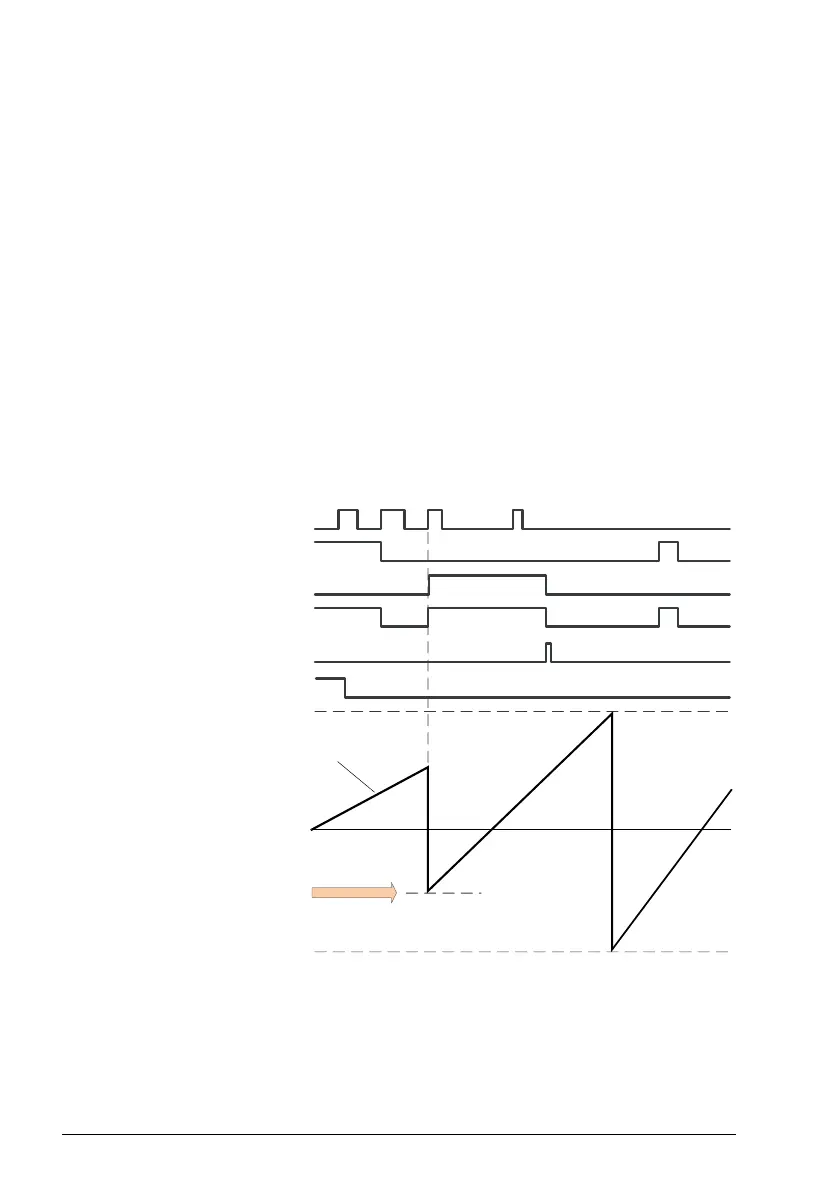

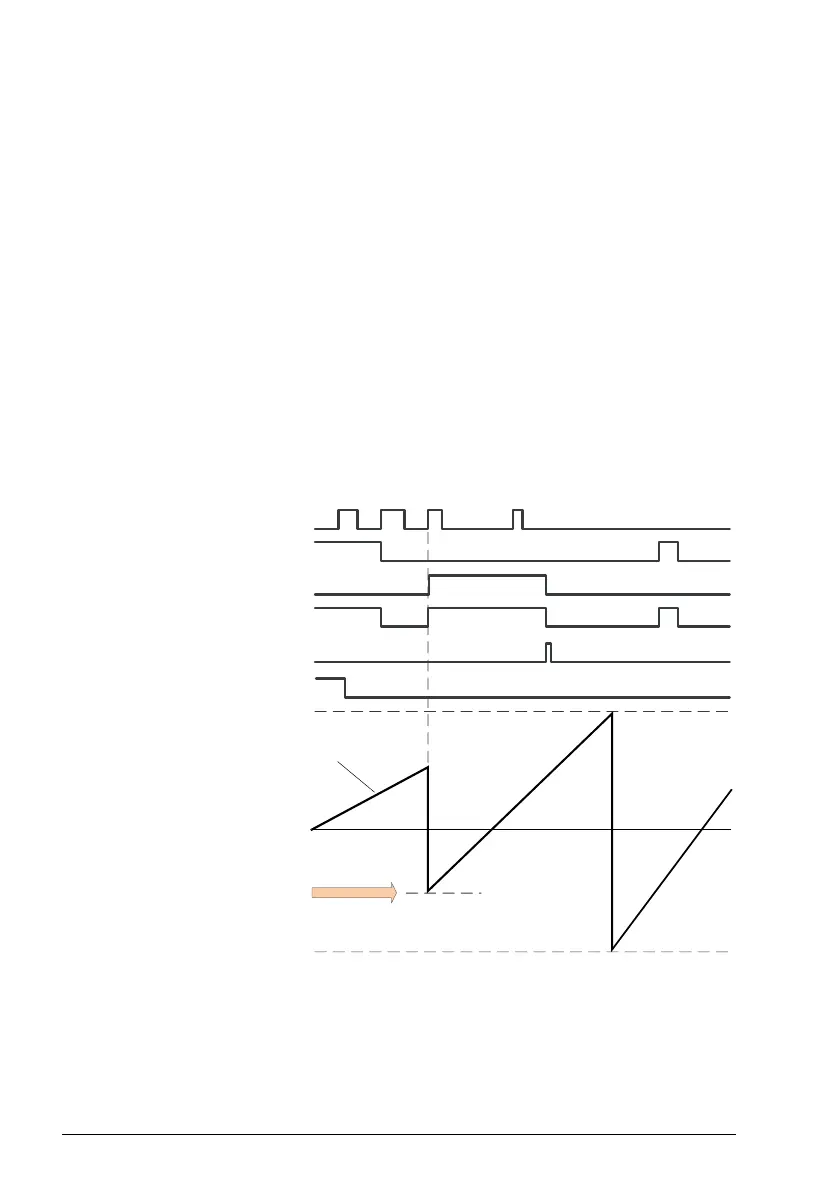

(Proximity switch) Source set by 90.67

1

0

1

0

1

0

1

0

1

0

1

0

(Initialization inhibit) Source set by 90.68

90.35 Pos counter status

bit 4, Pos counter init ready

(Re-init request) Source set by 90.69

Drive fault

90.07 Load position scaled int

(Initial value) Source set by 90.59

(by default, 90.58)

90.35 Pos counter status

bit 5, Position counter re-init disabled

0

Loading...

Loading...