MODULE 2: BASIC OPERATION

2-6 ARCHITECT

®

RSH Service Training Guide

FOR INTERNAL USE ONLY 201532-102

Sample Processing

• Samples are loaded into Carriers

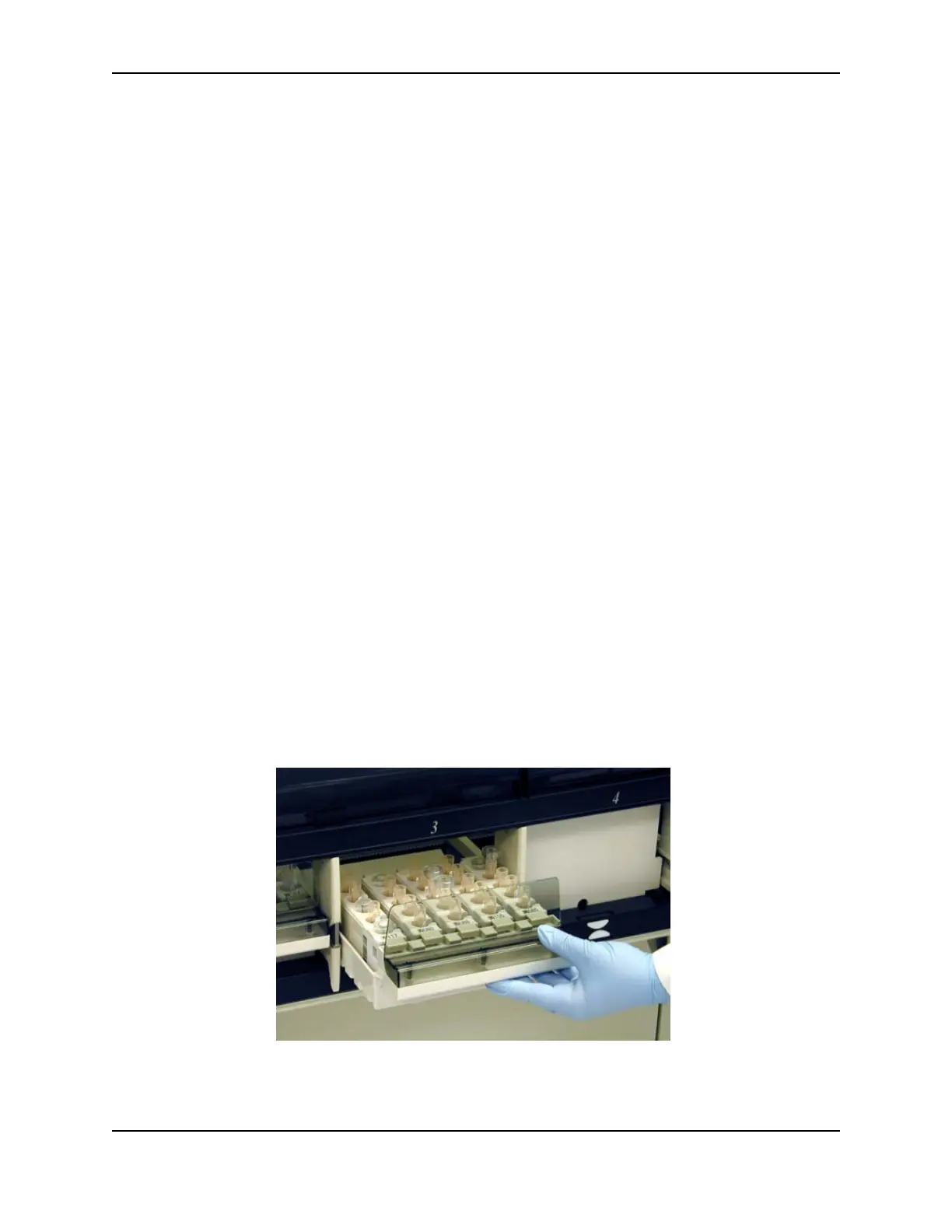

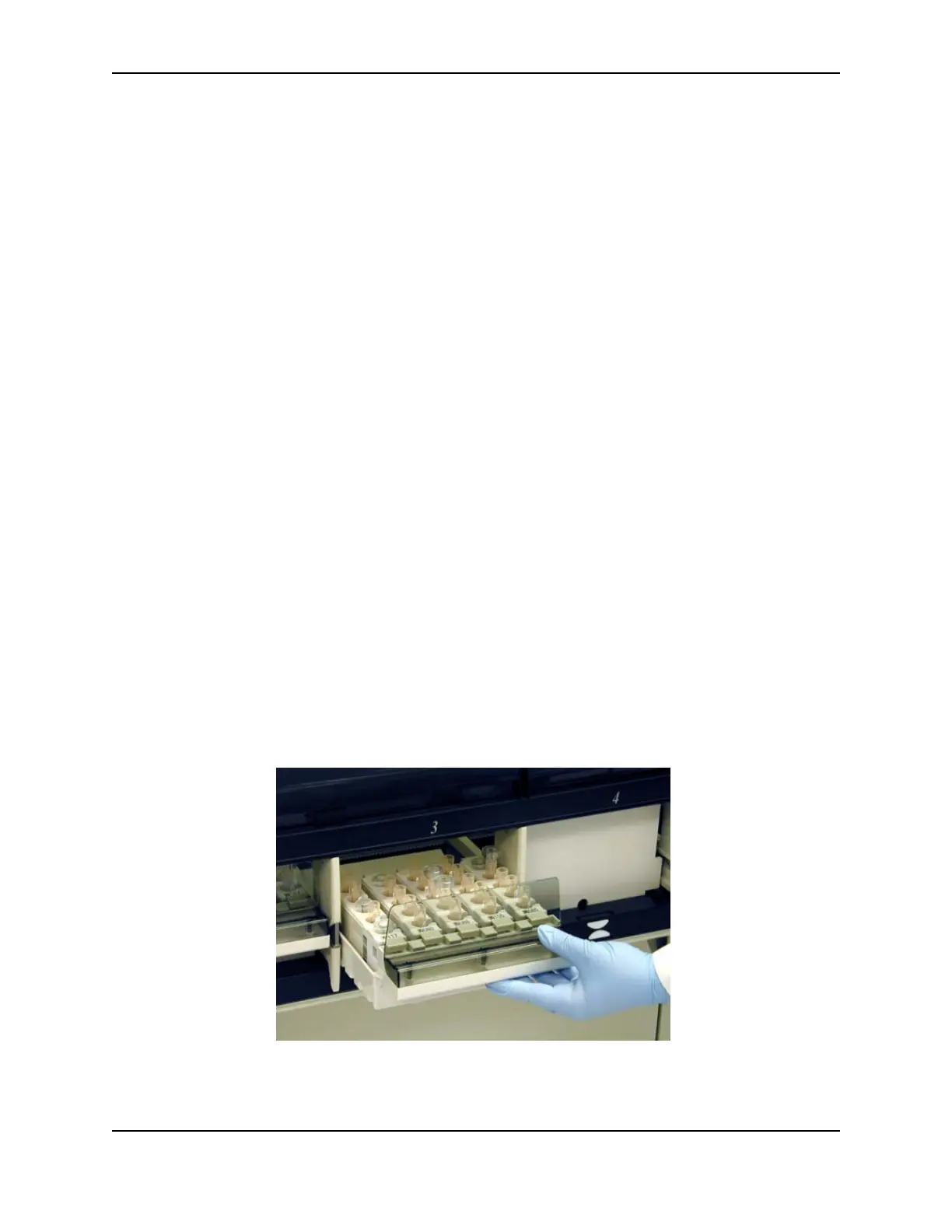

• Carriers are slid into RSH priority sections or placed into Carrier Trays which are slid into the

Routine Bays for sampling.

- Trays and/or Sample Carriers may be inserted into a position with a status of Access

(indicated by a steady green light)

• A robotic mechanism, called the Carrier Transport Assembly, is used to transport the Sample

Carriers from:

- the bay to the RSH Bar Code Reader

- The RSH Bar Code Reader reads the Sample Carrier ID Label and sample tube

bar code label

- RSH Bar Code Reader to the Carrier Positioner Assembly

- The Carrier Positioner moves Sample Carriers into position for aspiration by

the Processing Module Sample Pipettors

- When sample aspiration is complete for all samples in a Sample Carrier at a

particular Processing Module, the RSH transports it to the next processing

module in the system for further processing as applicable

- When a Sample Carrier contains samples with a mixture of assay

orders, the Sample Carrier is usually transported to the chemistry

PM first and then to the immunochemistry analyzer

- the Carrier Positioner back to the bay.

- When all tests for all samples in a given Sample Carrier are aspirated, the

Sample Carrier is returned to its original bay

• Indicator lights located on the front of the RSH provide Sample Carrier status information to

the operator.

Carrier Tray placed into Routine Bay

Loading...

Loading...