ADT-HC4500 Flame/Plasma Cutting Machine CNC System

- 72 -

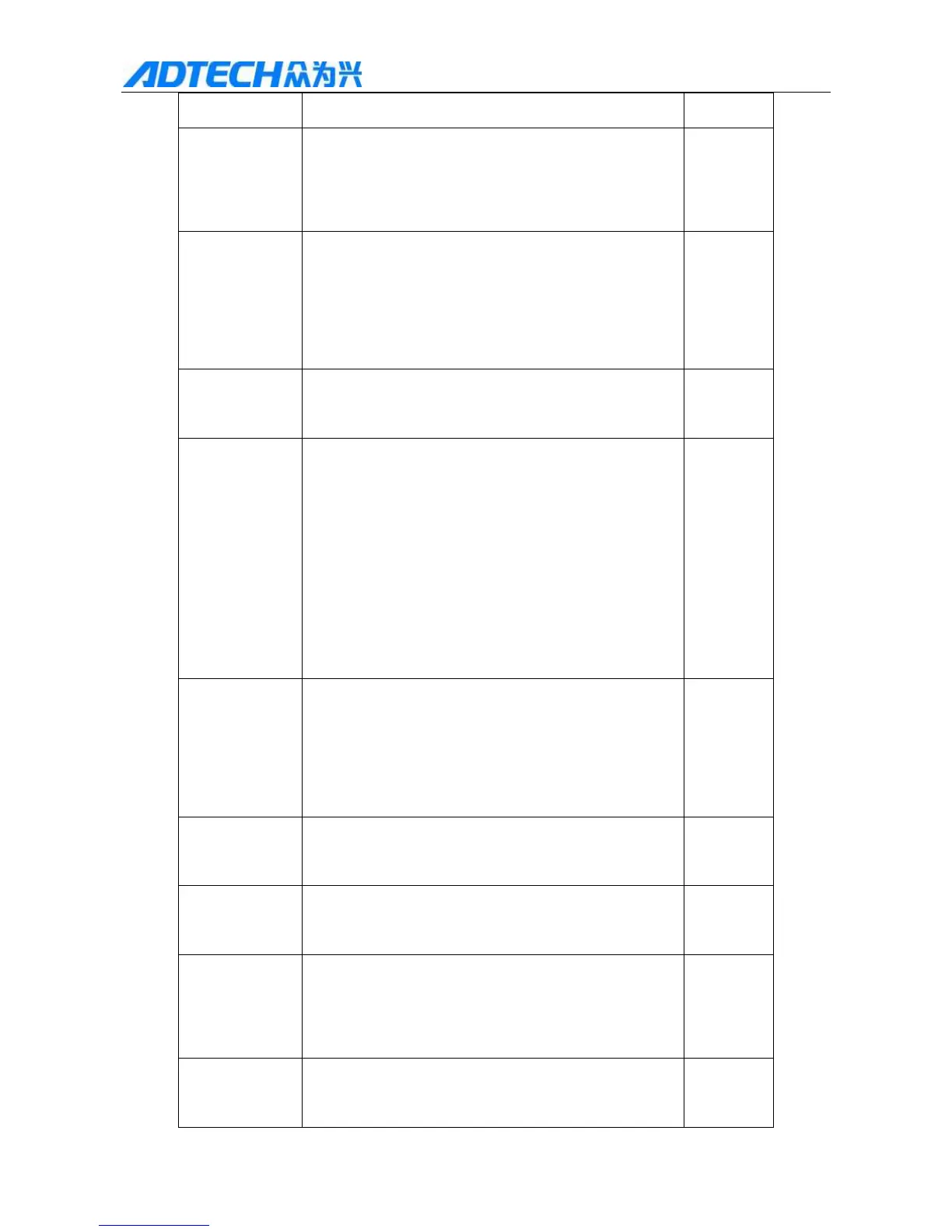

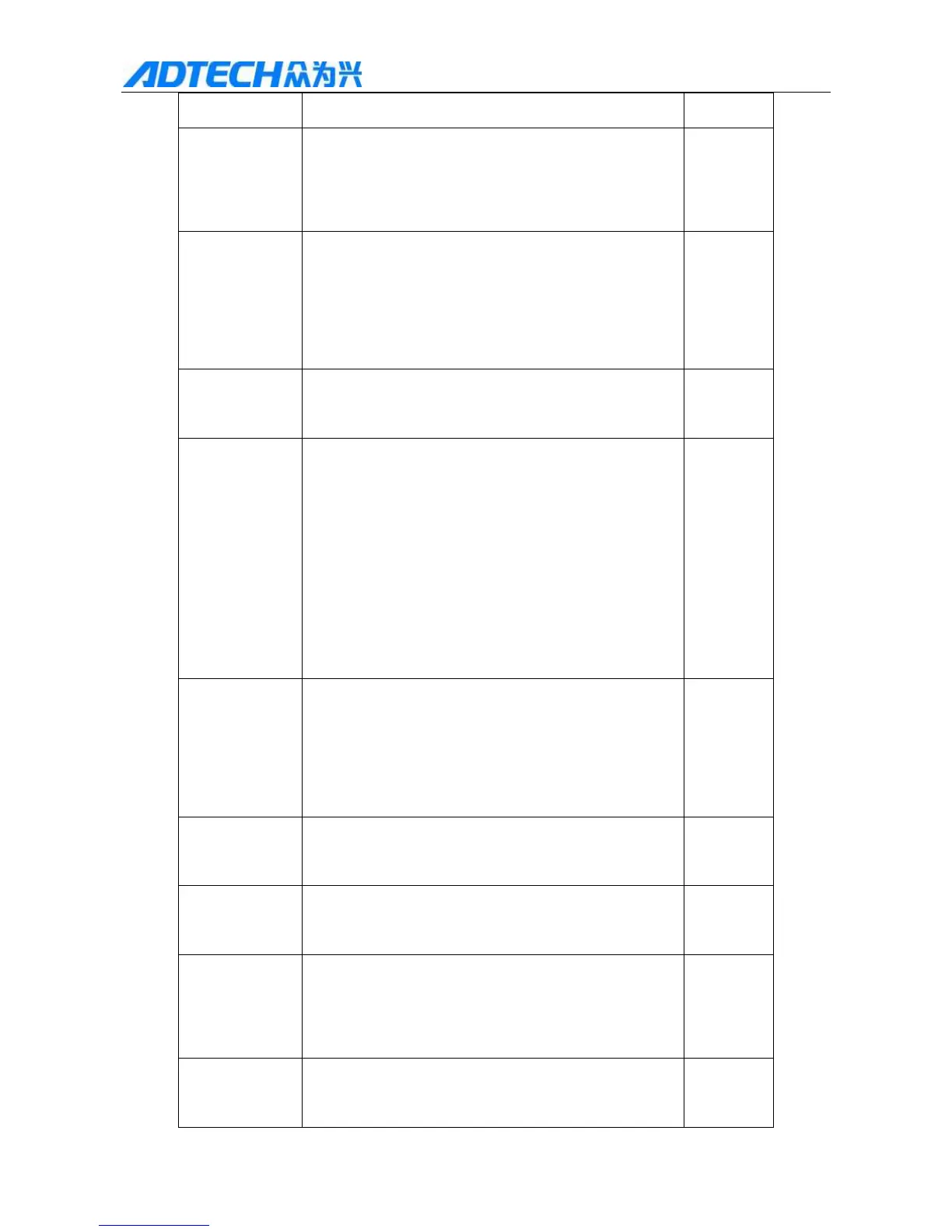

can be adjusted

Torch up delay Used before G00 transferring position to raise the torch to

an appropriate height, preventing the torch and steel plate

from colliding

0.01 sec

Torch down

delay

Counter action of torch up delay lowers the torch to an

appropriate height; after transferring G00 and before

processing, the torch must be lowered; the dropping time

of torch is shorter than rising time due to gravity.

0.01 sec

Ignition delay The time that high voltage ignition coil electrified while

igniting

0.01 sec

Perforating torch

up

In the fixed cycle of preheating perforating, when the

preheating ends, torch rises quickly and perforating torch

delays. At this moment, cutting oxygen turns on, torch

starts dropping, perforating torch down delays. Torch

rising before turning on cutting oxygen will prevent the

steel chip blocking the torch nozzle while turning on

cutting oxygen

0.01 sec

Perforating torch

down

In the fixed cycle of preheating perforating, torch drops,

and the fixed cycle ends after the perforating torch down

delay. The dropping time of torch is shorter than rising

time due to gravity.

0.01 sec

Start arc delay After arc switch is started, a delay is required before

processing (plasma processing)

0.01 sec

Perforating

delay

After arc switch is started, a continuous start arc time is

required to avoid unsuccessful arc start

0.01 sec

Height

adjustment

control

If the speed is smaller than this parameter during G01,

G02, G03 code motion, height adjustment is turned off

(plasma processing)

%

Positioning up

time

Set initial positioning up time during plasma processing 0.01 sec

Loading...

Loading...