15. Observe the positioning of the Block

Probe Cable, and gently remove it from

the Sample Cooling Assembly. Also note

the distance that the Block Probe is

inserted into the Sample Cooling

Assembly.

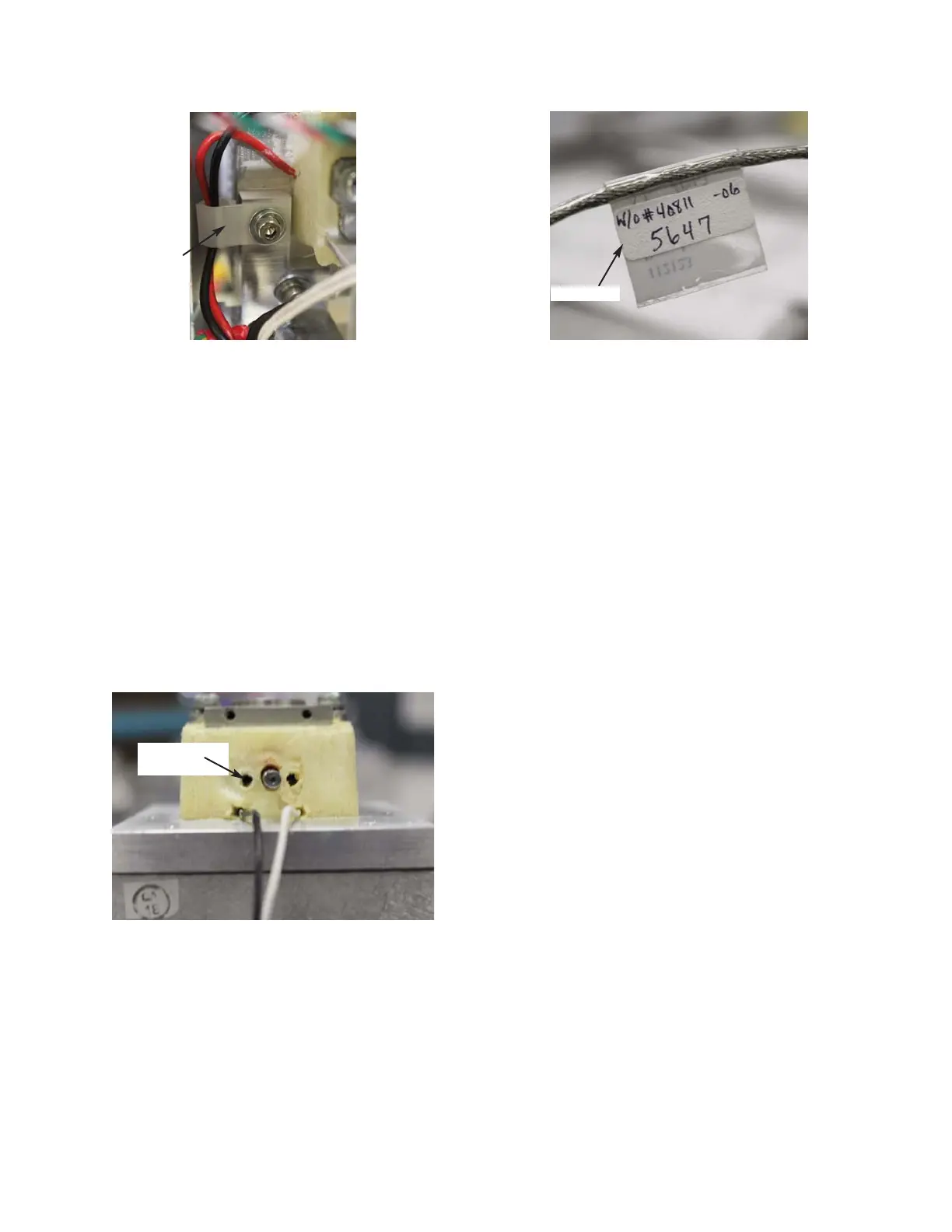

16. Insert the tip of the syringe (filled with

Thermal Grease) all the way into the

Block Probe hole. Inject the Grease into

the hole while slowly withdrawing the tip

to prevent the formation of air pockets.

Fill the hole with Grease (

Figure 10).

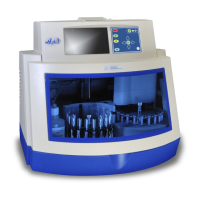

17. Record the resistance value listed on the

label of the Block Probe Cable. This

information must be entered into the

instrument’s set-up, and it will need to be

re-calibrated (

Figure 11).

18. Slowly, insert the replacement Block

Probe Cable into the Block Probe hole to

avoid causing any damage to the Probe,

and to ensure that the Thermal Grease is

properly displaced. Once the Block

Probe Cable has been fully inserted, hold

it in place until the excess Thermal

Grease has stopped oozing out of the

hole; wipe away any residual grease.

After the excess Thermal Grease has exit-

ed the Block Probe hole, the Block Probe

Cable will remain in place by itself.

Figure 11

112123RPM Rev0

(OsmoPRO Service Manual)

Page 4 of 6

Figure 9B

Figure 10

Block Probe

Hole

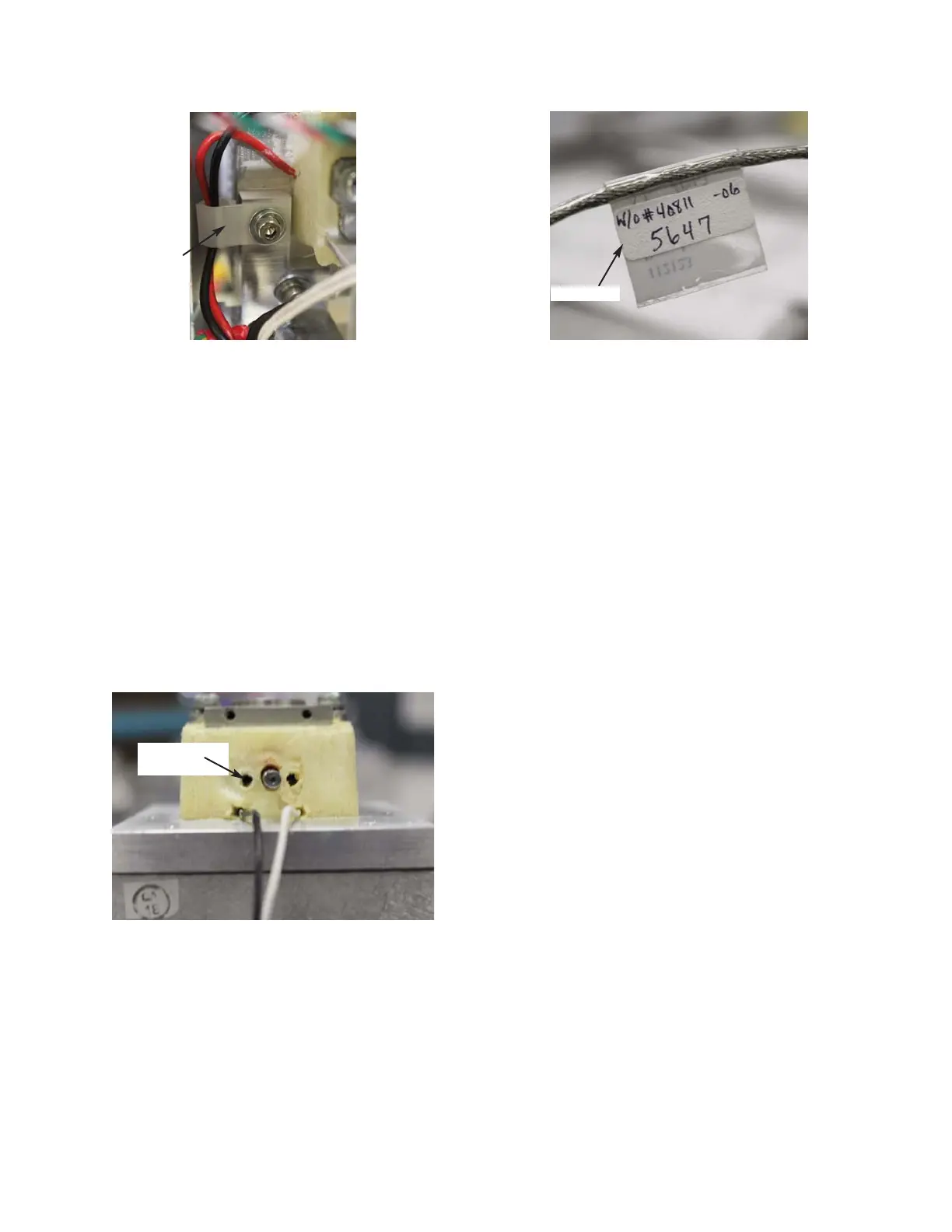

Cable Clip

BPC Label

Loading...

Loading...