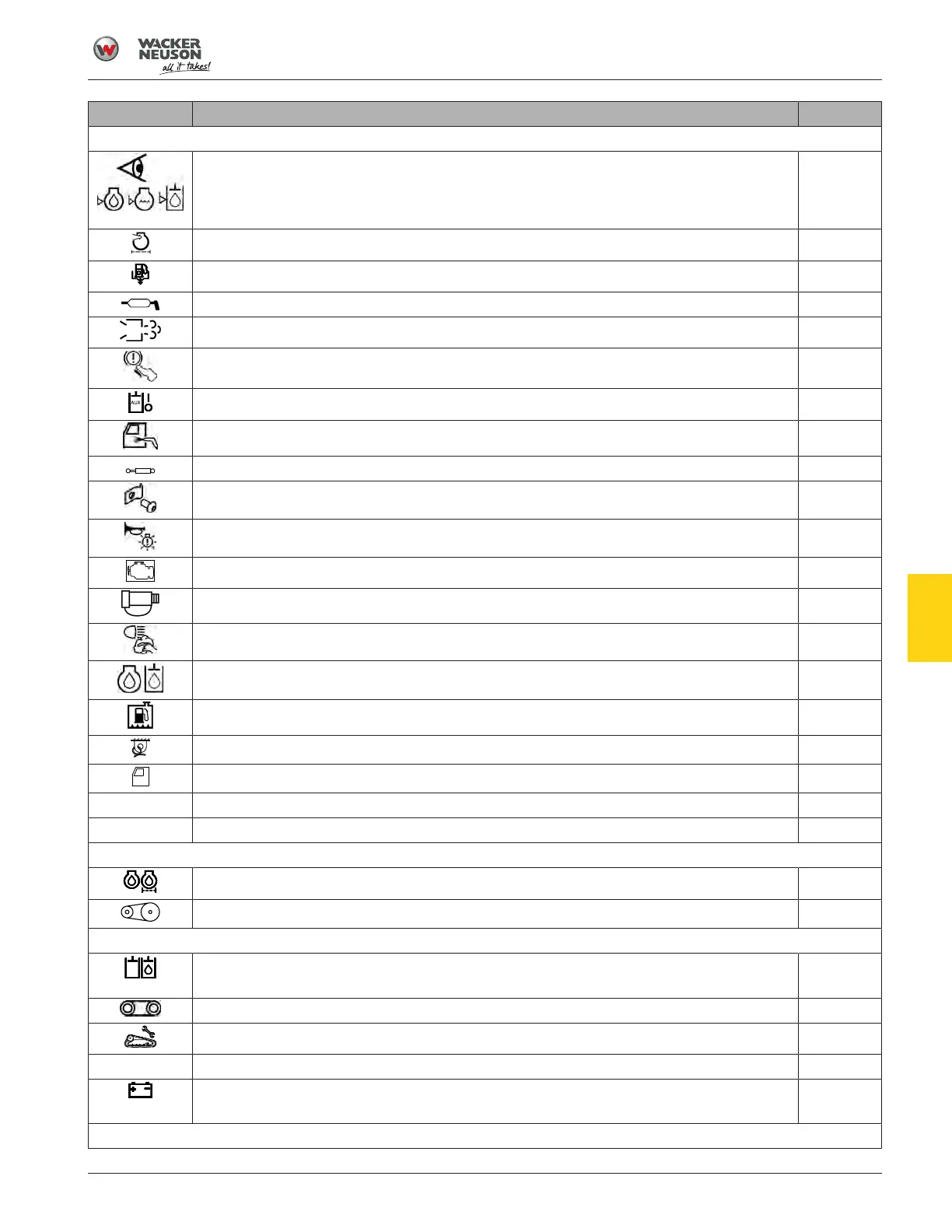

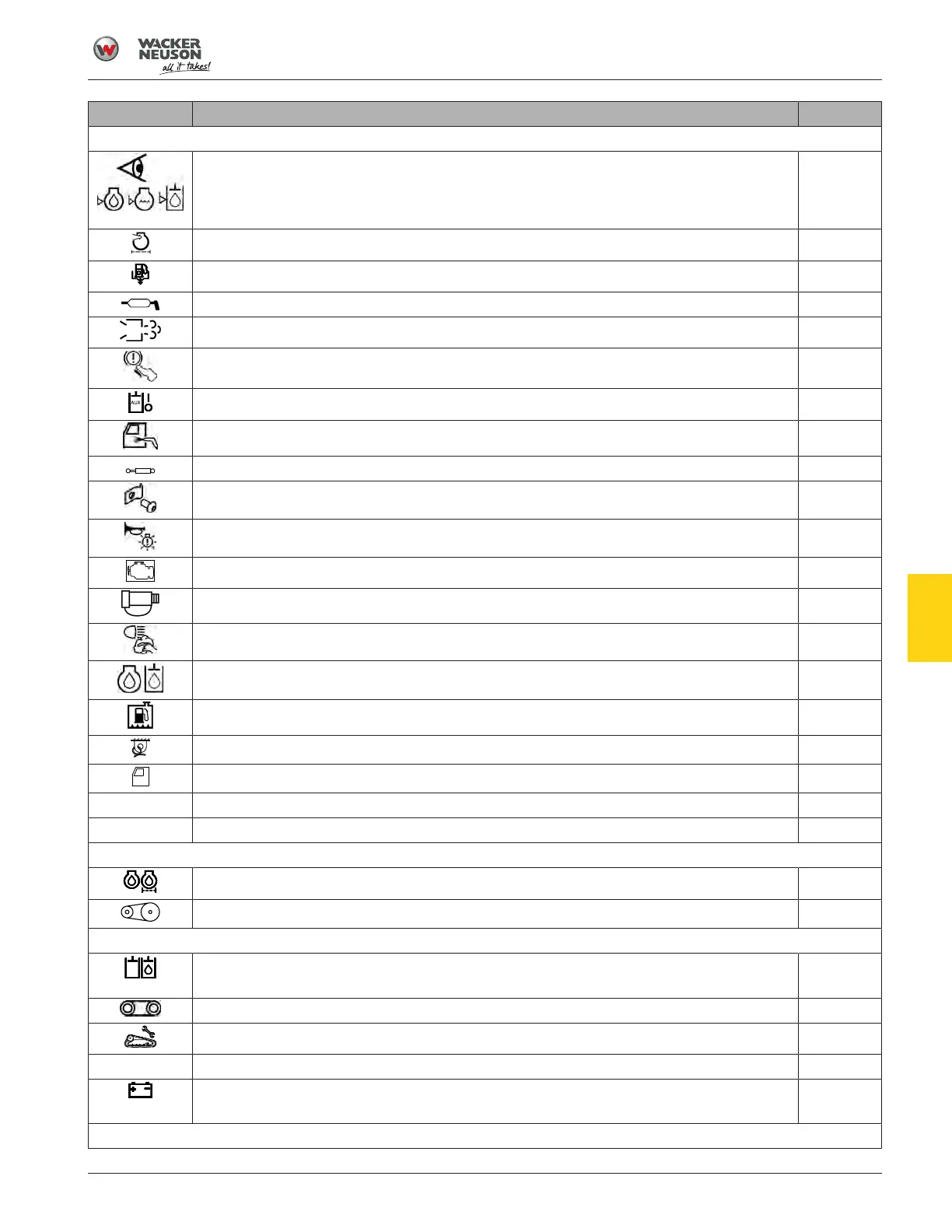

Maintenance

Maintenance Label 7.2

69

[en-US] | 08/2022 | 5100064108 | SM100 | Operator’s Manual

Symbol Task Reference

Every 10 Operating Hours (Daily)

Check the fluids and lubricants (engine oil, engine coolant, hydraulic oil).

[}79]

[}75]

[}76]

Check the engine air filter condition indicator for leaks and damaged components.

[}71]

Check the water separator.

[}81]

Lubricate the machine according to the lubrication plan.

[}72]

Check the exhaust system for damage.

[}82]

Check the service and parking brake function.

[}71]

Check the continuous flow shutoff system for proper function.

[}83]

Check access panels for dirt.

[}71]

Check the piston rods of the cylinders for damage.

[}71]

Check the line fixtures.

[}71]

Check the indicator lights and acoustic warning devices.

[}71]

Check the engine compartment for damage.

[}71]

Check the hydraulic couplings for dirt.

[}71]

Clean the lights/light system and signaling systems.

[}71]

Check the engine and hydraulic system.

[}71]

Check the fuel tank level and fill as needed.

[}63]

Check the tie-down points for damage.

[}71]

Check and clean the operator platform.

[}71]

— Check the interlocks for proper function.

[}77]

— Check for damaged safety labels. Replace damaged labels.

[}71]

Only Once after the First 50 Operating Hours

Replace engine oil and filter.

[}85]

Check condition of all drive belts. Adjust or replace as needed.

[}87]

Every 50 Operating Hours

Check the hydraulic fluid, hoses, and tubelines for damage and leaks. Repair or re-

place as needed.

[}89]

Check the tracks (damage, tension, profile).

[}92]

Check the undercarriage for loose bolts and nuts.

[}89]

— Drain the water separator.

[}81]

Check battery for damage and recharge. Check cables, connections, and electrolyte

level.

[}98]

Every 250 Operating Hours

7

Loading...

Loading...