Maintenance

Checking and Adjusting Track Tension 7.22

93

[en-US] | 08/2022 | 5100064108 | SM100 | Operator’s Manual

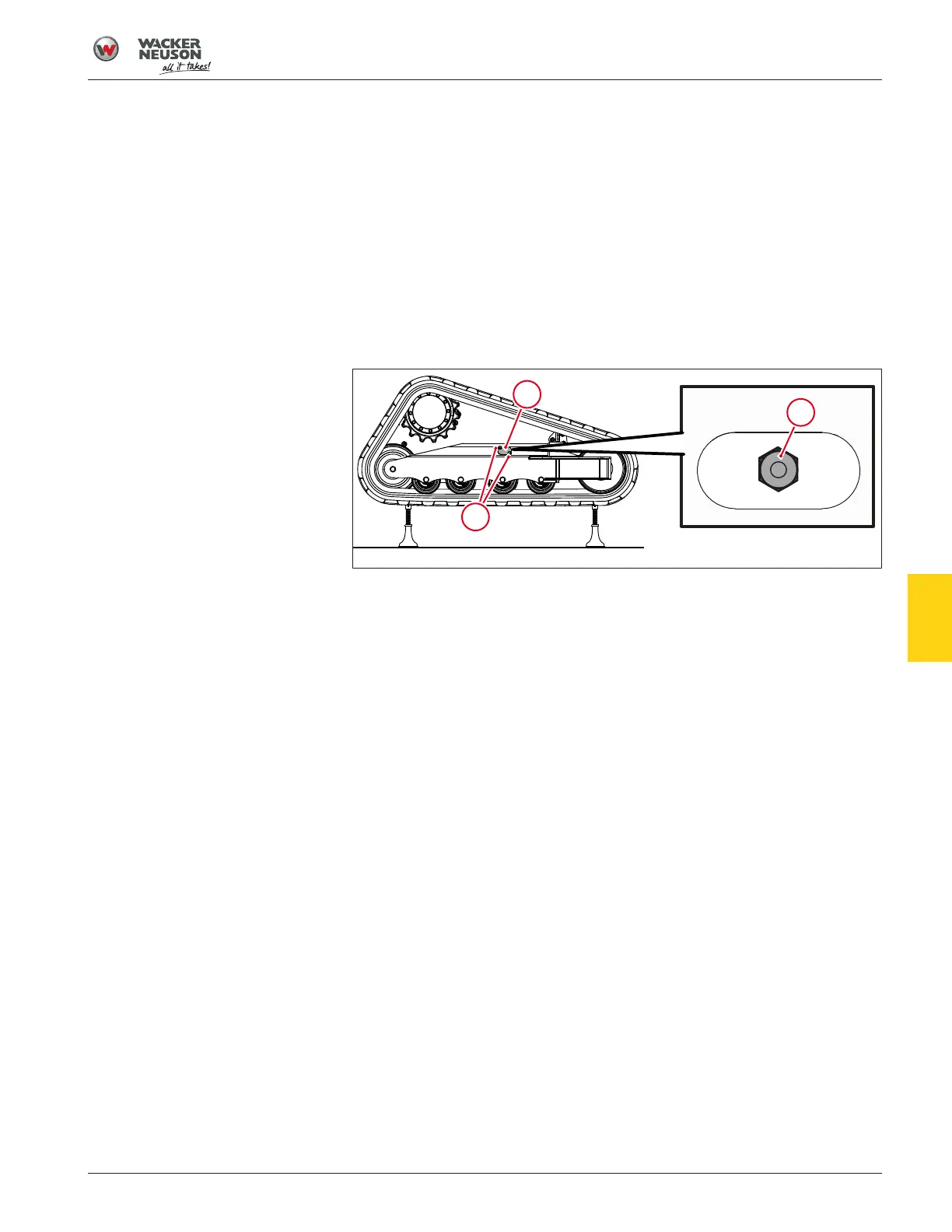

Checking track tension

1. Raise the machine using a floor jack and jack stands.

ð Be careful not to position the jack stands over the belly pan cover.

2. Adjust the track tension if the track sag distance between the bottoms

of the two middle rollers and the track is between 15 and 18mm (0.56

and 0.71 in.).

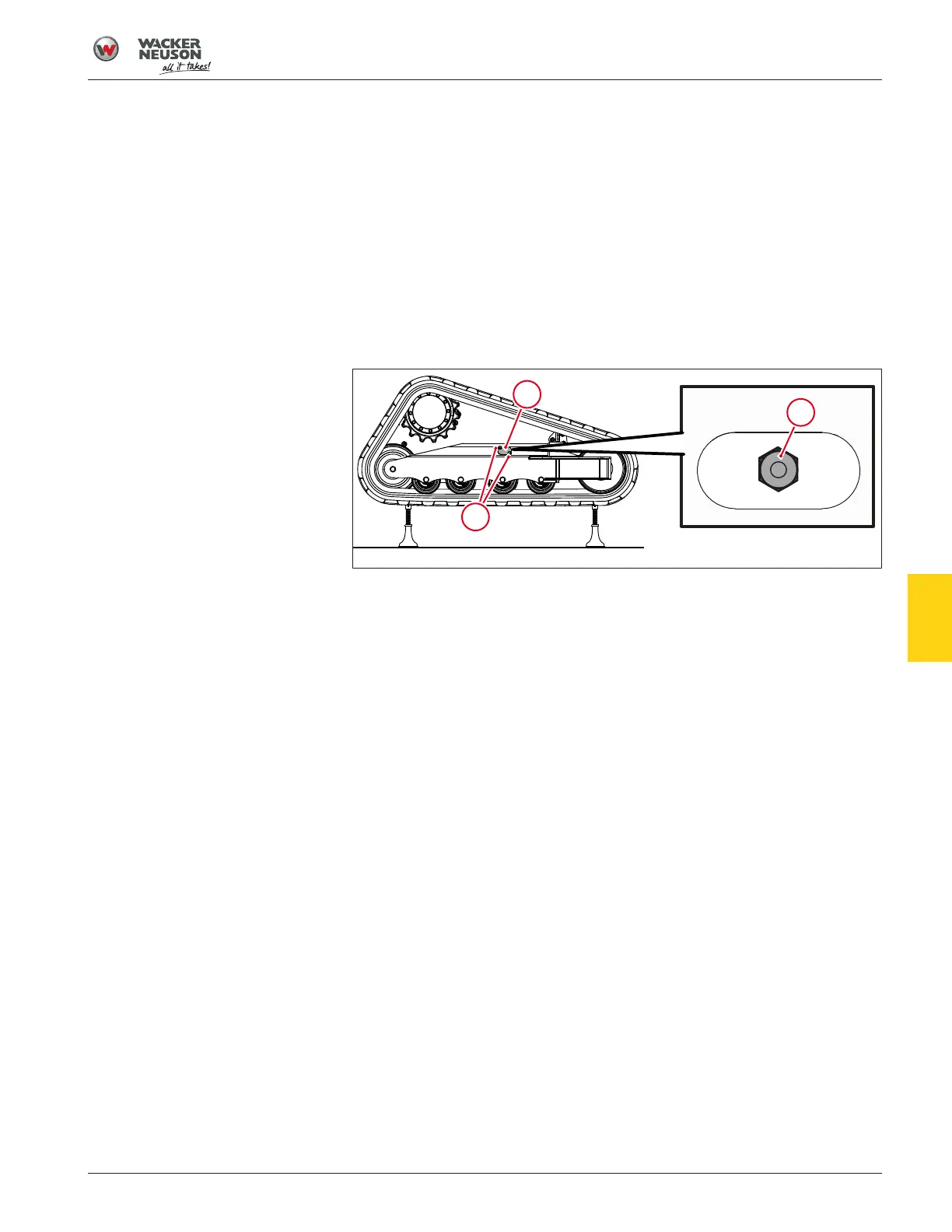

Increasing track tension

1. On the side of the machine that needs its track adjusted, loosen the

screws (1) securing the grease valve cover and swing the cover (2)

down.

Fig.82: Screws and cover

2. Apply grease into the valve (3) with a grease gun.

3. Check the track tension again. The track sag distance between the bot-

toms of the two middle rollers and the track should be between 15 and

18mm (0.56 and 0.71in.). If the track tension is still out of specifica-

tion, apply more grease into the valve.

4. If the track still does not have enough tension after applying grease

again, do not put the machine into operation. Contact a Wacker Neu-

son dealer.

5. Lower the machine to the ground.

6. Install the cover.

Reducing track tension

1. On the side of the machine that needs its track adjusted, loosen the

screws securing the grease valve cover and swing the cover down.

2. Slowly turn the valve counterclockwise to release the grease into a

suitable container.

ð The grease flows out of the groove of the valve.

3. Tighten the valve until it is snug.

4. Check the track tension again. The track sag distance between the bot-

toms of the two middle rollers and the track should be between 15 and

18mm (0.56 and 0.71in.). If the track tension is still out of specifica-

tion, repeat the procedure for increasing or reducing track tension as

needed.

7

Loading...

Loading...