3.6.2.2 Big-end bearing

Procedure

1.

Fit the bearing shells together and tighten the screws.

2.

Measure the I.D. using a cylinder gauge which has been zeroed to the diameter of the respective

bearing journal. If the clearance exceeds 0.14 mm with new bearing shells, the big-end journals

require grinding. Refer to the specifications for the correct undersize and the corresponding bearing.

NOTE: Ensure that the radii at the end of the bearing journals are not altered when grinding.

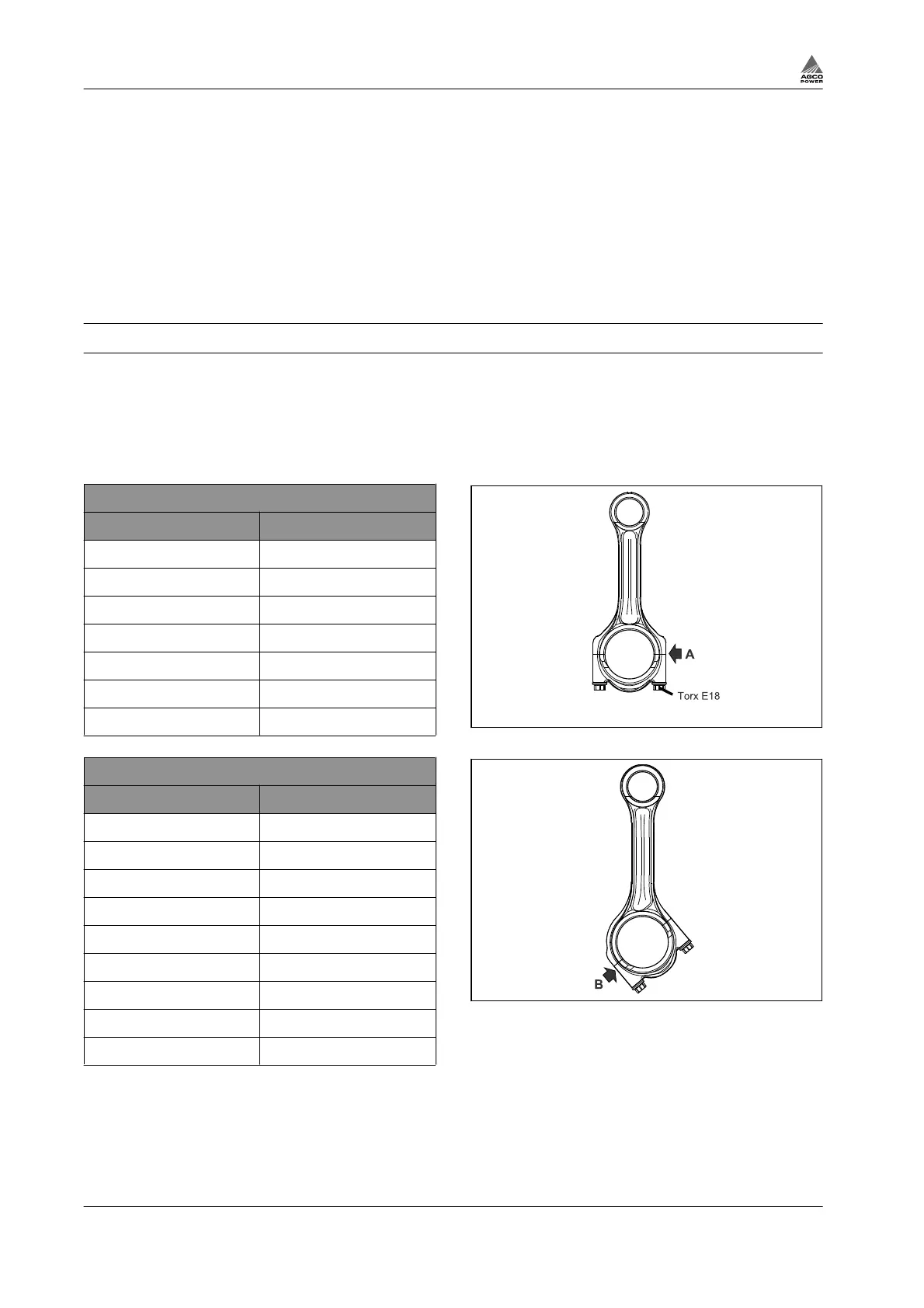

3.6.3 Checking connecting rod

The connecting rod is checked in a special fixture, intended for the purpose (e.g. Carl Larsson).

The connecting rods are divided into weight classes with intervals of 20 g. The weight class (a letter) is

stamped on the side face of the connecting rod. All the connecting rods in one engine should be of the

same weight class, that is to say the greatest permissible weight difference is 20g.

NOTE: Always change connecting rod screws, when opened.

Weight class (33-74 engines)

Letter (A) Weight

F 1935 - 1954 g

V 1955 - 1974 g

X 1975 - 1994 g

Y 1995 - 2014 g

W 2015 - 2034 g

Z 2035 - 2054 g

G 2055 - 2074 g

Fig. 50

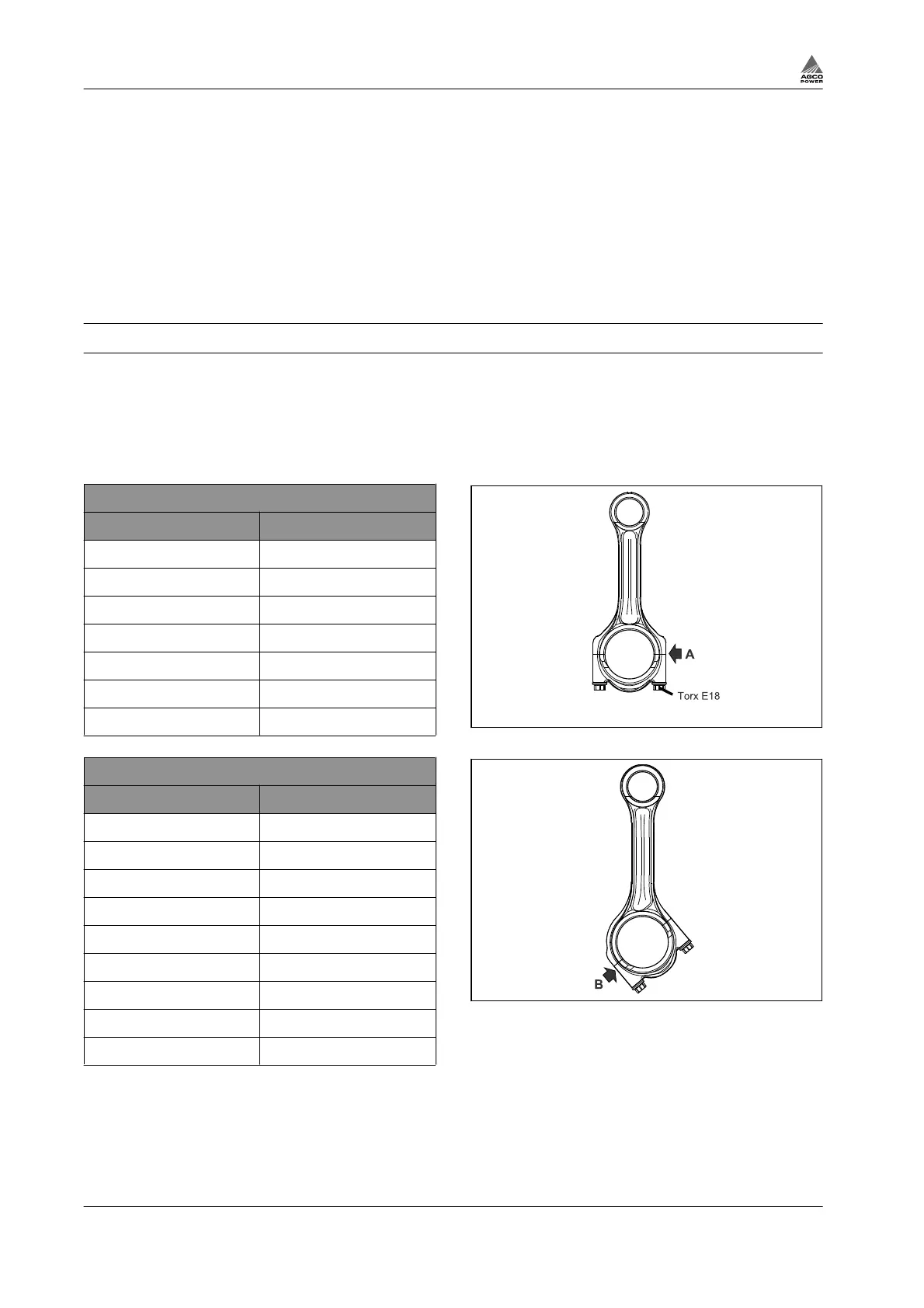

Weight class (84-98 engines)

Letter (B) Weight

E 2330 - 2349 g

F 2350 - 2369 g

G 2370 - 2389 g

H 2390 - 2409 g

I 2410 - 2429 g

J 2430 - 2449 g

K 2450 - 2469 g

L 2470 - 2489 g

M 2490 - 2509 g

Fig. 51

3. Maintenance

3-32 4th Generation Engines

8370 79492

Loading...

Loading...