3.2 Flywheel housing

3.2.1 Fitting flywheel housing

The flywheel housing is centred on the cylinder block by two tension pins. Even the flywheel housings

which are delivered as spare parts have ready-made holes for the pins.

Procedure

1.

Clean the sealing surfaces between the

cylinder block and the flywheel housing.

2.

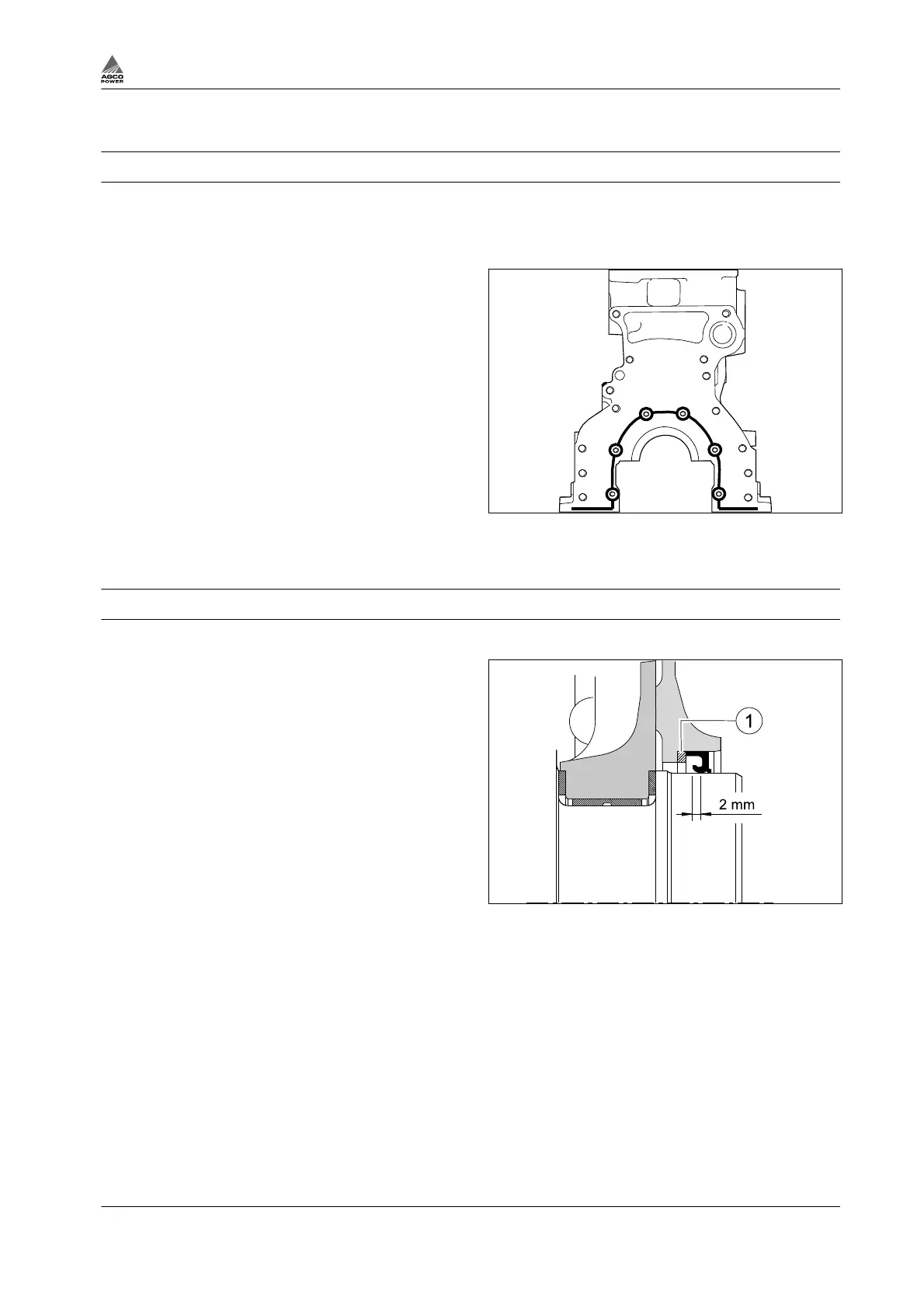

Apply silicone sealant 8366 62741 as shown

in the figure.

3.

Lift the flywheel housing into place and fit all

the bolts.

4.

Centre the housing with centring tool 9052

46400. Centre the housing with centring tool

9104 52700 (84 and 98 engines). Note! This

is important for engines with a turbine clutch.

5.

Fit the tension pins with drift 902598700.

6.

Apply thread sealant Loctite 572 to the fixing

bolts reaching oil or water spaces.

7.

Tighten the fixing bolts to the correct torque

value.

Fig. 15

3.2.2 Changing crankshaft rear oil seal

Procedure

1.

Lift out the engine.

2.

Remove the clutch assembly (and if

applicable the turbine clutch).

3.

Remove the flywheel.

4.

Remove the oil seal.

Do not damage the crankshaft.

5.

Clean the seal location and grind off any

burrs.

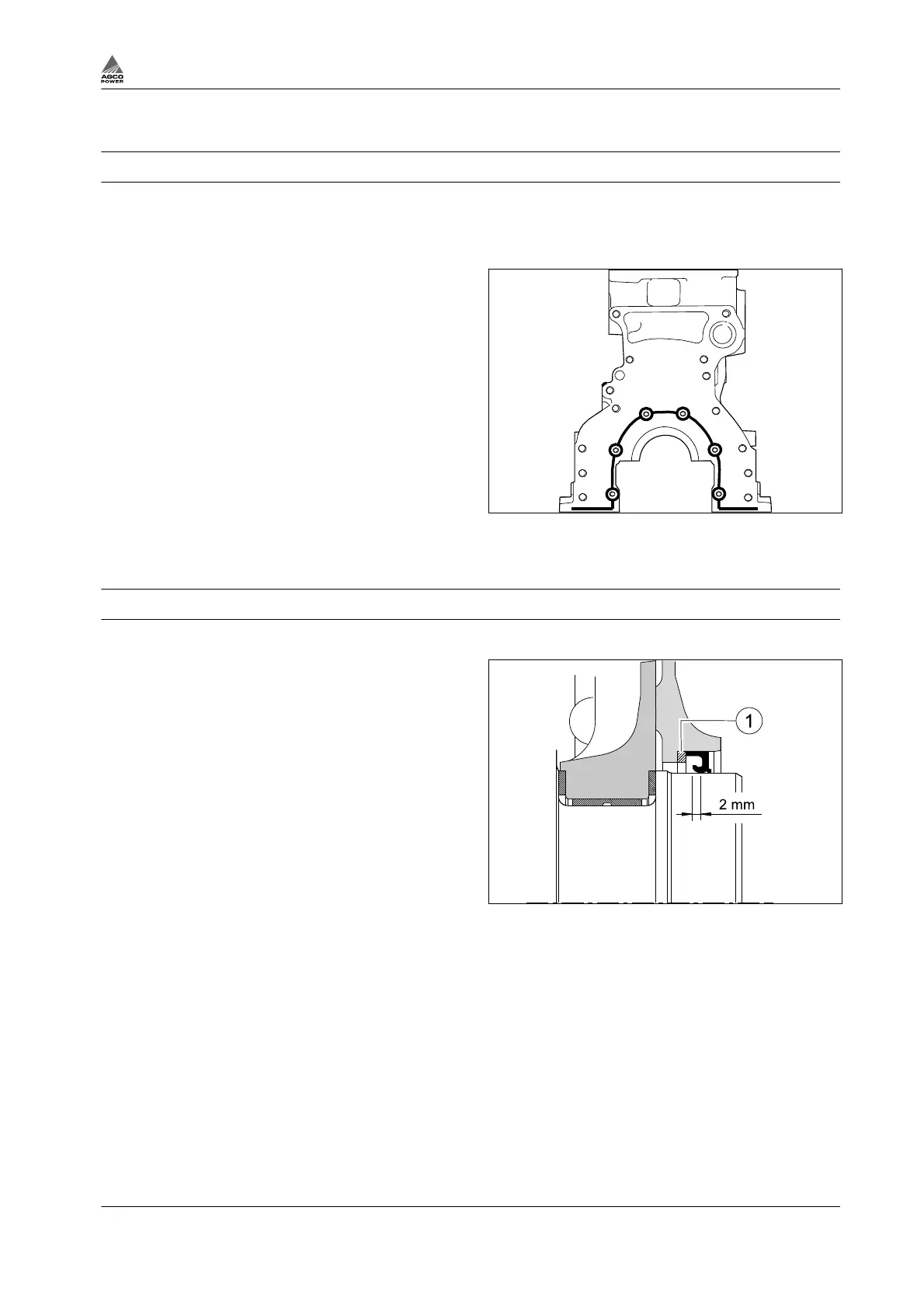

NOTE: If the crankshaft is worn at the

sealing location, a 2 mm spacer ring, can be

fitted in front of the crankshaft rear oil seal.

Fig. 16

(1) Spacer ring

3. Maintenance

4th Generation Engines 3-13

8370 79492

Loading...

Loading...