3.10 Lubrication system

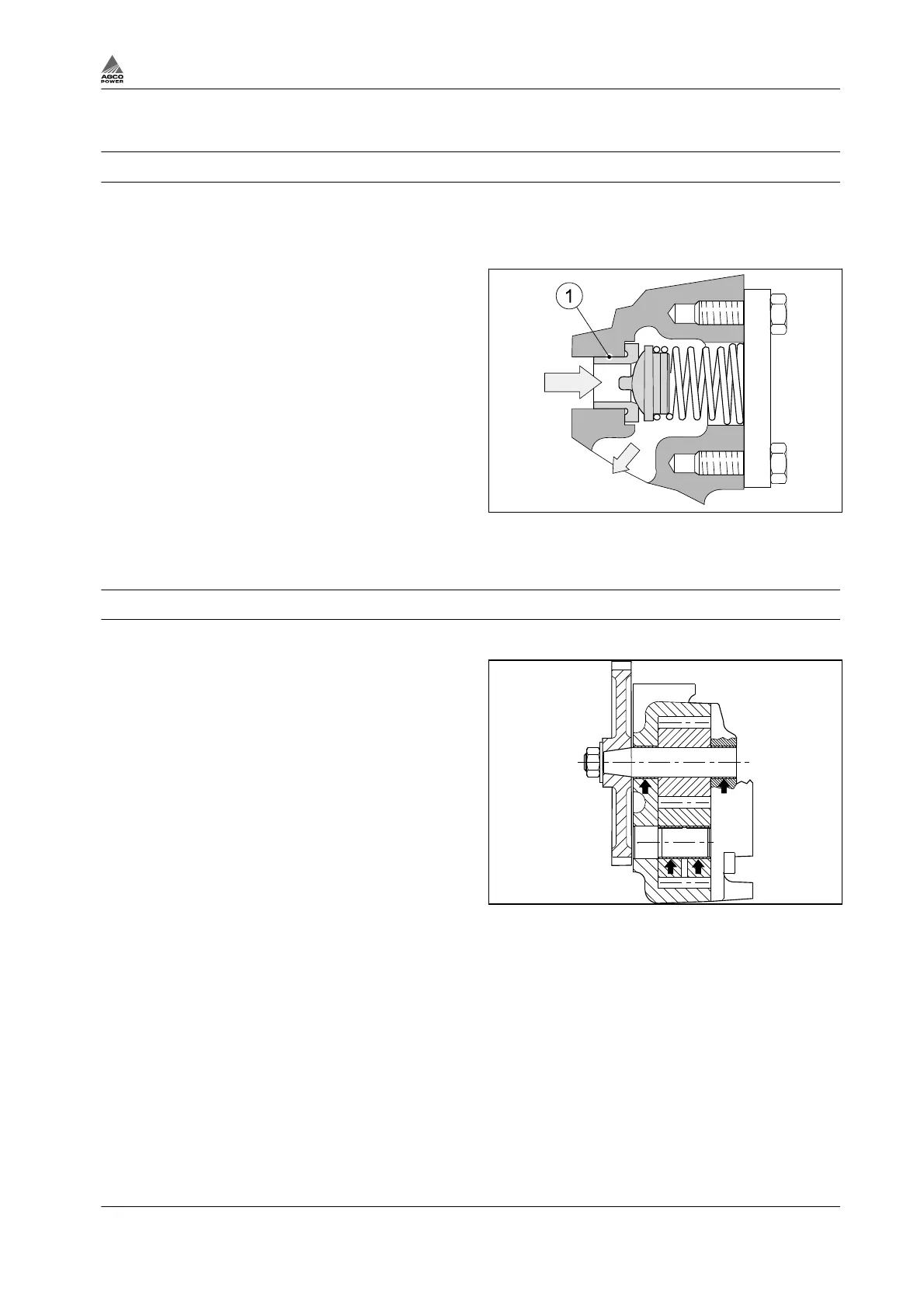

3.10.1 Oil pressure regulating valve

If the pressure of the engine lubricating oil is insufficient or varies, the oil level and then the oil pressure

regulating valve need to be checked.

Procedure

1.

Remove the cover and the spring with the

valve plate.

2.

Clean the parts and check that the sealing

surfaces are undamaged.

Damaged parts must be changed.

NOTE: There are two types of spring.

3.

Scrape off any remains of the gasket.

4.

Apply locking fluid (for example Loctite 638)

onto the outside of the valve seat.

5.

Tap the new valve seat into the cylinder

block using a suitable drift.

6.

Fit the spring with valve plate into the

cylinder block and fit the cover with a new

gasket.

Fig. 73

(1) Loctite 638

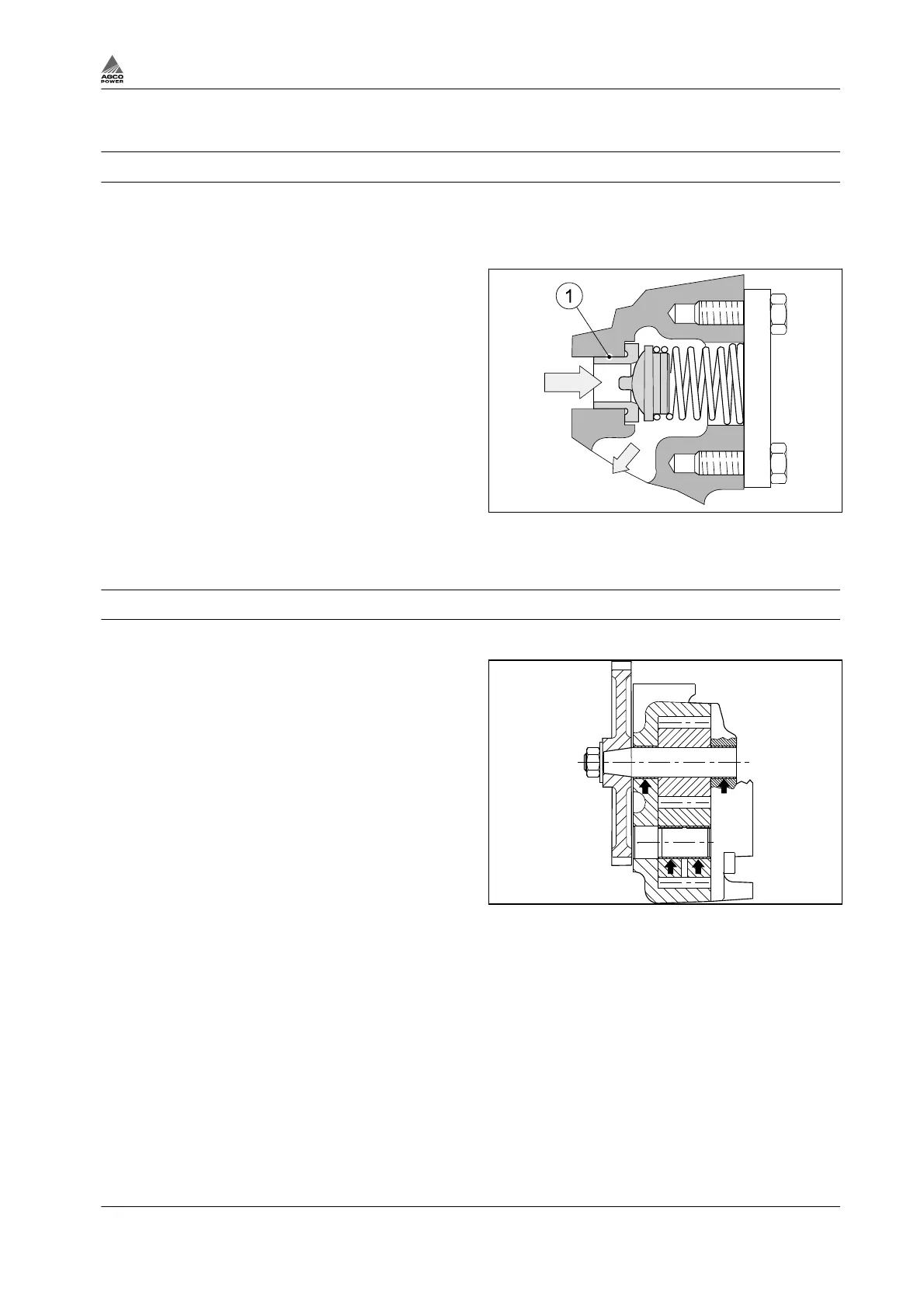

3.10.2 Removing and dismantling lubricating oil pump

Procedure

1.

Drain the engine oil and remove the oil

sump.

2.

Remove the oil pump suction and pressure

pipe.

3.

Remove the oil pump together with any

shims between the pump and the cylinder

block.

4.

Remove the pump cover and the gasket.

Remove the gear on the dead axle.

5.

Clamp the pump gear across the teeth in a

vice fitted with soft jaws, and loosen the

drive gear nut.

6.

Knock the gear wheel off by hitting the end

of the shaft with a soft hammer.

7.

Pull out the drive shaft gear wheel.

8.

Clean the parts and check for wear and other

damage.

9.

Change damaged parts and all seals.

NOTE: The bearing points are provided with

separate bearing bushings in the 66-, 74-, 84-

and 98-engines. If you change the bushings,

machine them to the correct size after fitting.

Fig. 74

3. Maintenance

4th Generation Engines 3-45

8370 79492

Loading...

Loading...