3.3.4 Changing valve guides

Procedure

1.

Press or knock out the old valve guides using

drift 9120 85300.

2.

Clean the valve guide locations.

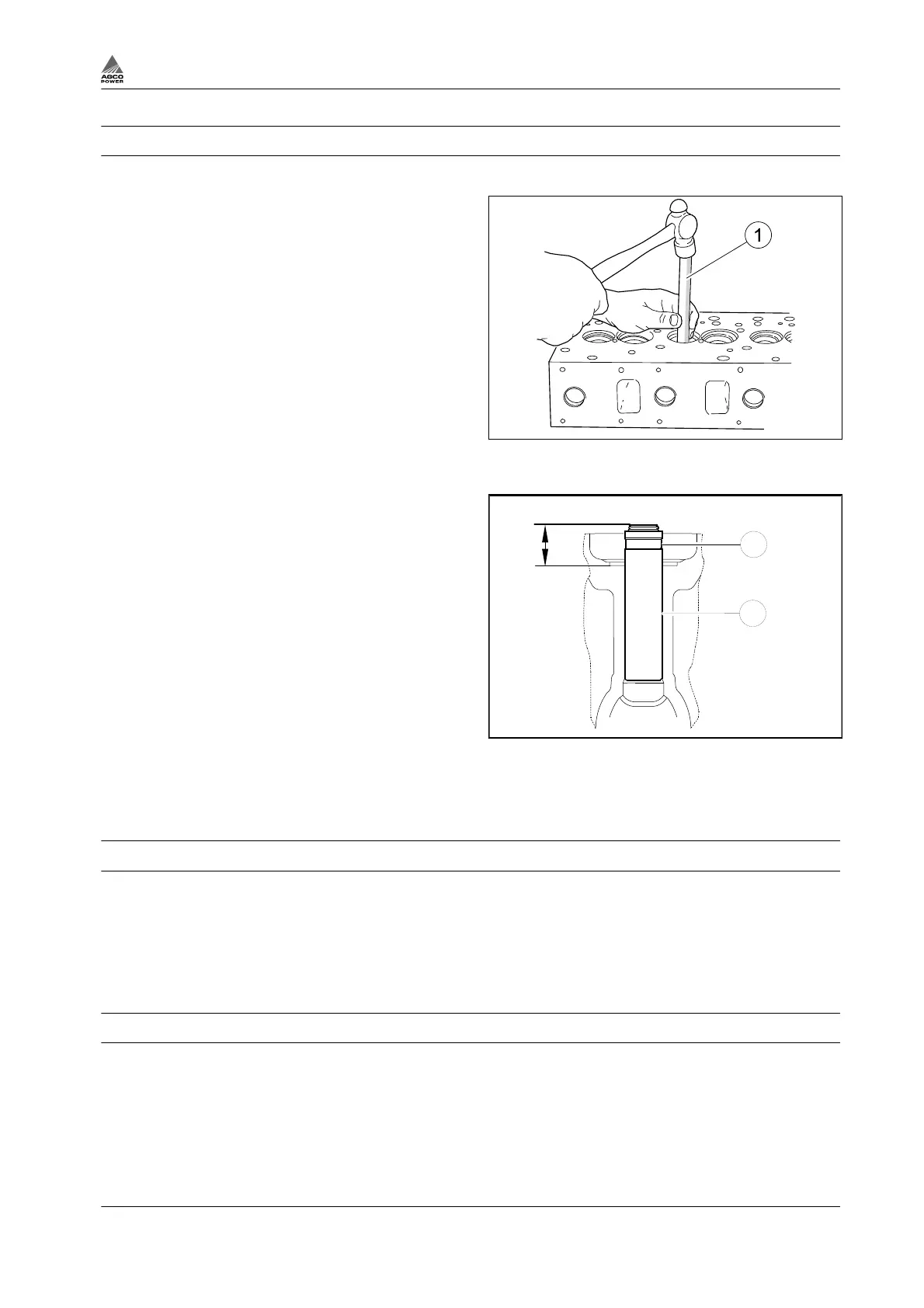

Fig. 21

(1) Drift 9120 85300

3.

Lubricate the outside of the new valve

guides.

4.

Fit the valve guides using drift 9120 85000.

The drift makes sure the correct fitting height

(13 mm over the spring face).

The valve guides are the same for the inlet

and exhaust valves.

5.

Make sure that the sharp chamfer on the

guide faces the valve head.

6.

Check that the valves are moving freely in

the guides.

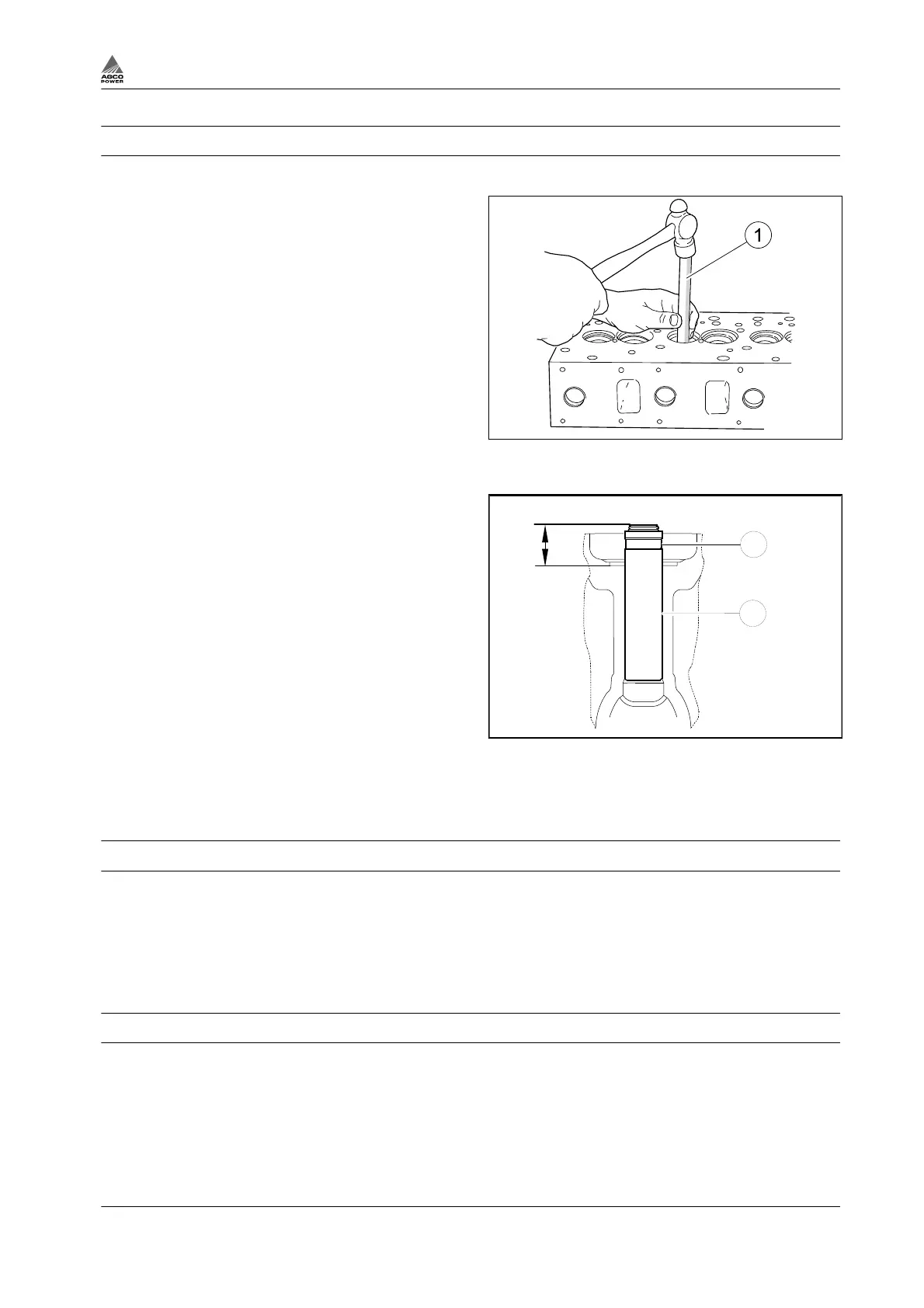

1

2

H

Fig. 22

(1) Valve stem gasket

(2) Valve guide

(H) 13 mm

3.3.5 Machining valve seat

Procedure

1.

Machine the damaged valve seat with milling cutter kit 8370 62635.

2.

If the width of the seat exceeds 2.0 mm in the exhaust and 2.2 mm in the intake, it should be

reduced primarily at the outer edge. The valve seat angle is 45°+20’ for the exhaust valve and 35°

+20’ for the inlet valve.

3.3.6 Changing valve seat rings

All valves are fitted with separate valve seat rings. If the sealing surface is damaged so badly that it cannot

be repaired with machining, the seat ring must be changed.

Procedure

1.

Grind the valve head on a discarded valve so that it sits down in the valve seat ring.

2.

Fit the valve and weld the valve in position in the valve seat ring.

3.

Cool with water.

3. Maintenance

4th Generation Engines 3-17

8370 79492

Loading...

Loading...