11.

Fit the protective plate into the front cover

seal location.

12.

Fit the crankshaft front seal with drift.

13.

Check and clean carefully the conical

surfaces on the crankshaft and the hub.

14.

Lubricate the parts.

a) Lubricate both the seal and the sealing

surface.

b) Lubricate the hub nut thread, rear surface

and outer surface (the surfaces affecting

nut friction) with vaseline.

NOTE: If the hub piece is worn out at the

sealing surface, a 3 mm spacer ring can be

fitted under the crankshaft rear oil seal (33 -

84 engines).

NOTE: Do not use oil, the oil can run into the

conical surfaces.

15.

98 engine: Fit the crankshaft hub.

See for additional information.

16.

33-84 engines: Fit the crankshaft hub.

17.

33-84 engines: Install the hub nut onto the

crankshaft thread.

18.

33-49 engines: Tighten the hub nut to 600

±100 Nm.

19.

66-84 engines: Tighten the hub nut to 1000

±100 Nm.

20.

Fit the other removed parts.

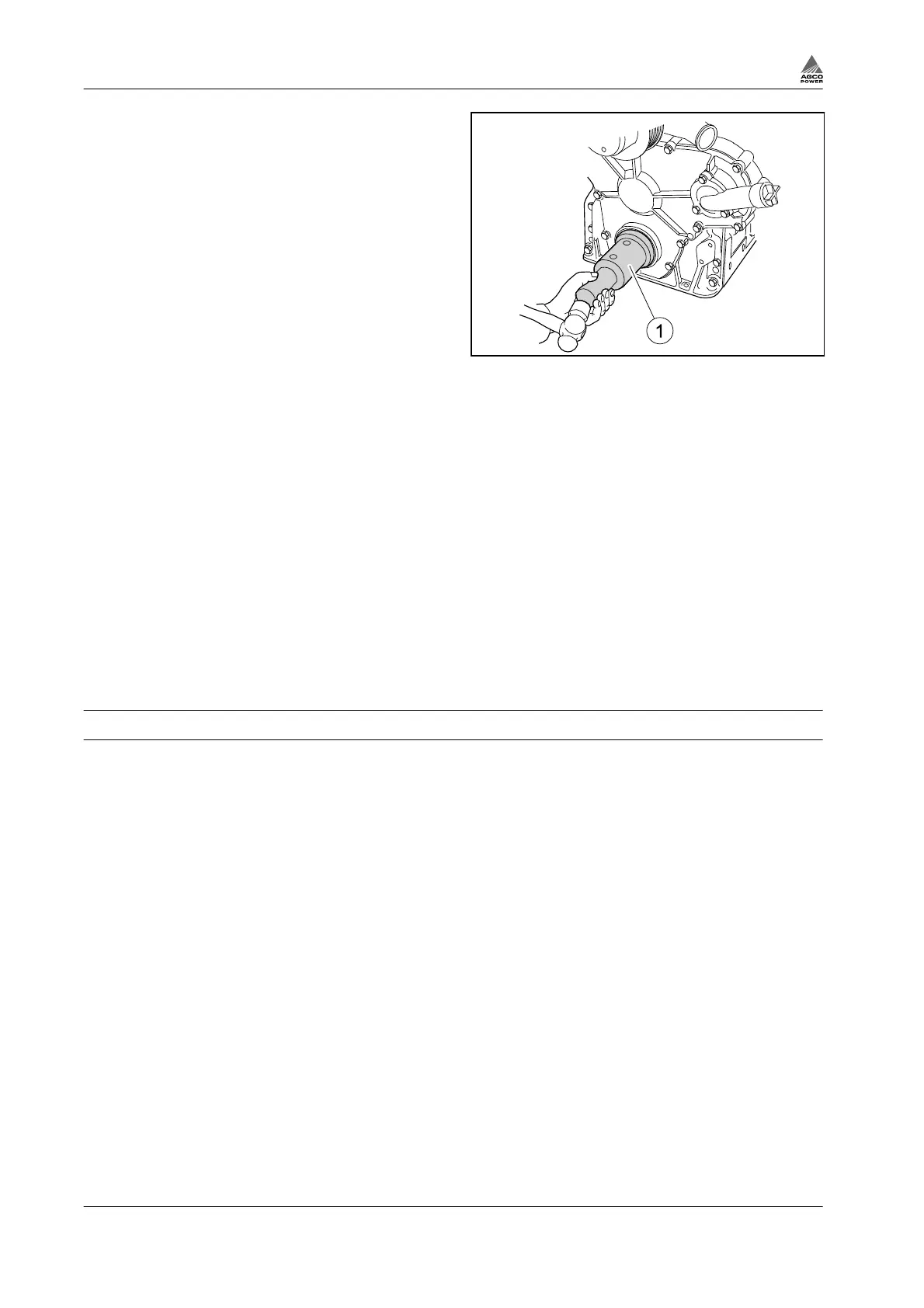

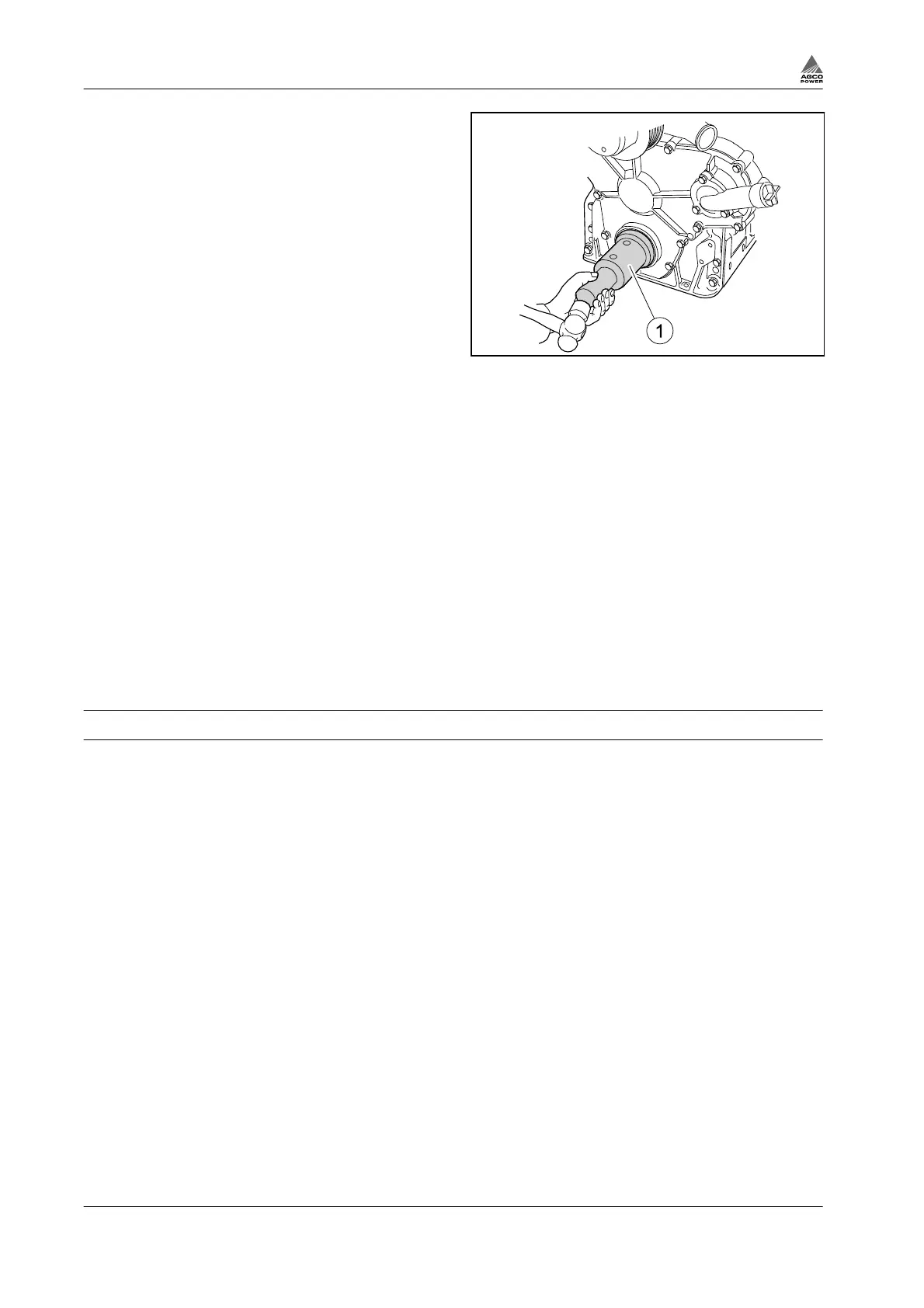

Fig. 68

(1) 33-84 engines: Drift 9103 94600

(1) 98 engine: Drift 9235 17520

3.9.3 Fitting the crankshaft hub

98 engines

The crankshaft hub is attached to the crankshaft with a separate conical sleeve.

When installing the hub must the conical surfaces be absolutely clean.

Procedure

1.

Check and clean carefully the conical

surfaces on the crankshaft and the hub.

2.

Lubricate the O-ring lightly with Vaseline and

install it into the groove in the hub.

3. Maintenance

3-42 4th Generation Engines

8370 79492

Loading...

Loading...