(5) Cooling pump

(6) Actuator

(7) Engine control unit

The cooled exhaust gas recirculation system (EGR) used on some AGCO POWER engines is controlled by

electronic engine control unit (ECU). Part of exhaust gases is led from exhaust manifold (1) through EGR

valve (2) to EGR cooler (3) where they are cooled with engine coolant. The cooled exhaust gas is mixed

with fresh intake air in intake manifold (4) before it flows to combustion chamber.

The cooled EGR system decreases the temperature in combustion chamber, which in turn results as lower

nitrogen oxide (NOx) emissions.

1.3.11.2 EGR cooler

The EGR cooler cools down the exhaust gases. The cooler is capable to decrease exhaust gas temperature

even with 50%.

1.3.12 Fuel system

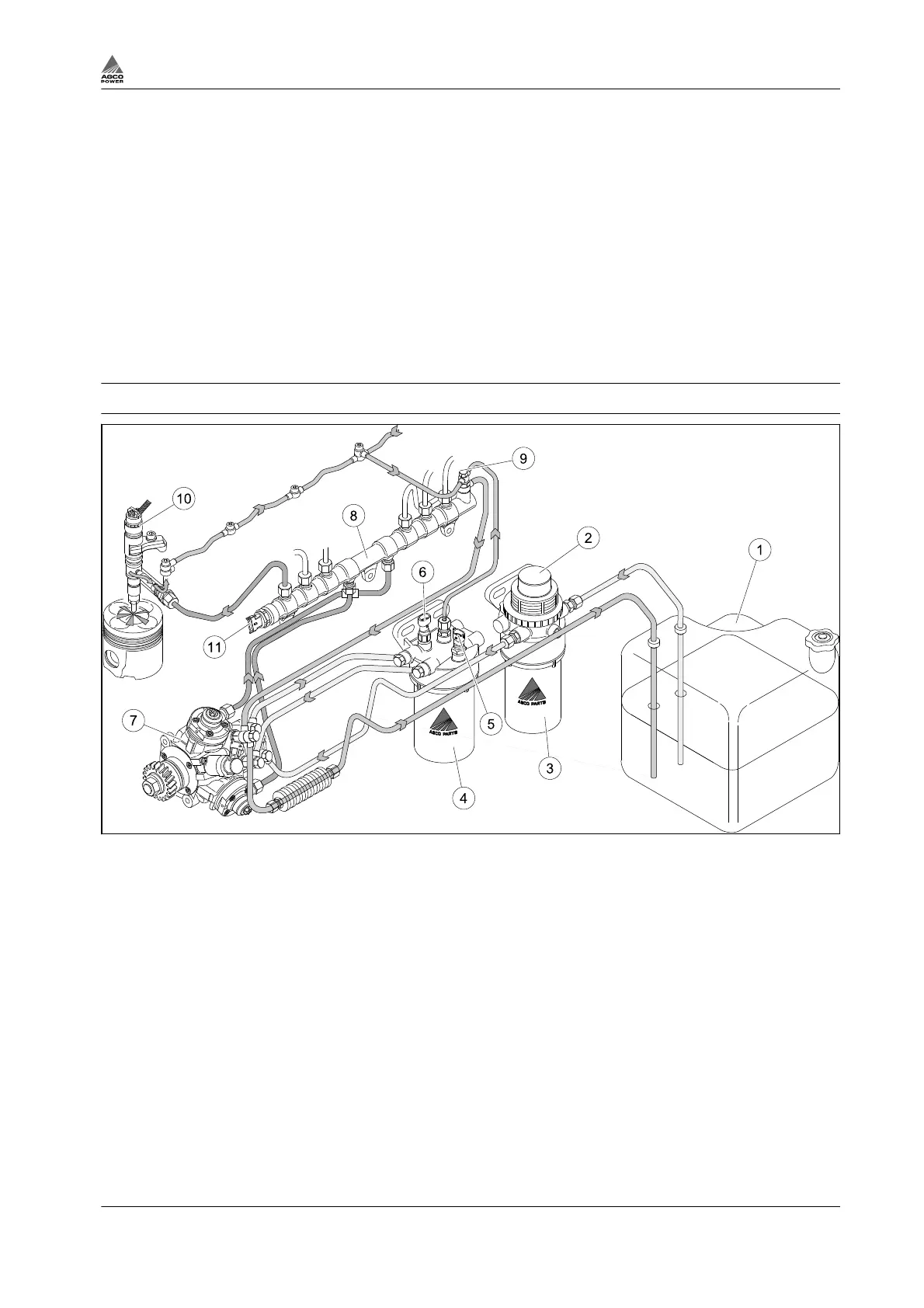

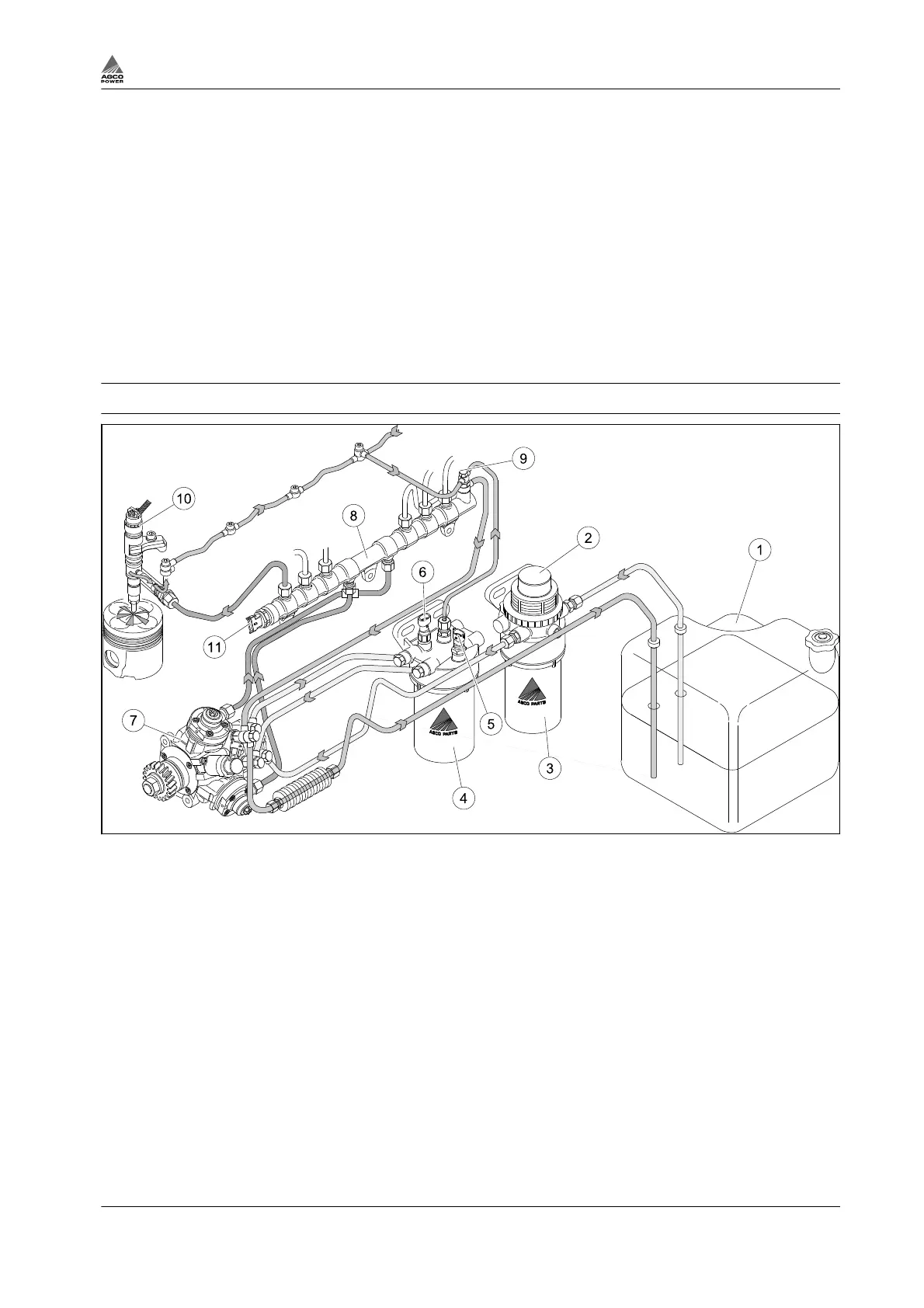

Fig. 18 Parts of fuel system, example construction

(1) Fuel tank

(2) Hand pump

(3) Pre-filter

(4) Fuel filter

(5) Fuel temperature sensor

(6) Fuel pressure sensor

(7) High-pressure pump

(8) Rail

(9) Overflow valve

(10) Injector

(11) Pressure sensor

Engines are equipped with common rail system which is controlled by electronic control unit (ECU).

Fuel is drawn from the tank via the pre-filter, through the main fuel filter to the high pressure pump. From

the high pressure pump, fuel is pumped up into the rail. This high pressurized fuel is lying in a high

pressure pipe where it is controlled and injected through electronic injectors that are controlled by EEM4.

The injection is optimized in terms of emissions, efficiency and operation noise and takes place in four

steps (maximum). Excess fuel returns from the injectors and pressure regulating valves of the high

pressure pump and rail back to the fuel tank.The overflow pipe from the filter helps the bleeding of the

system.

The fuel is diesel fuel according to the norm EN 590:2009 and it must be clean and free from water after

storage (see fuel quality requirements).

1. Introduction

4th Generation Engines 1-21

8370 79492

Loading...

Loading...