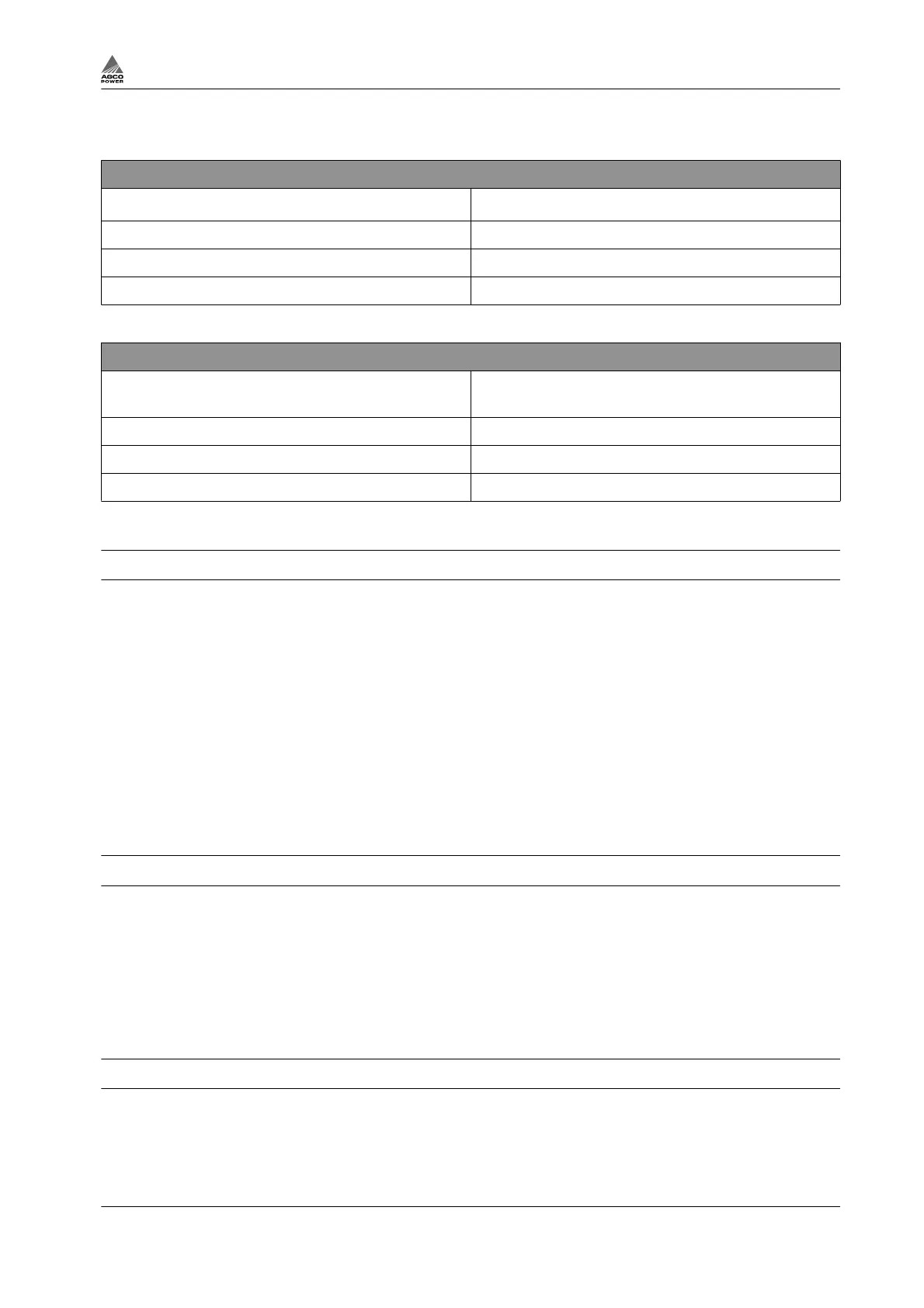

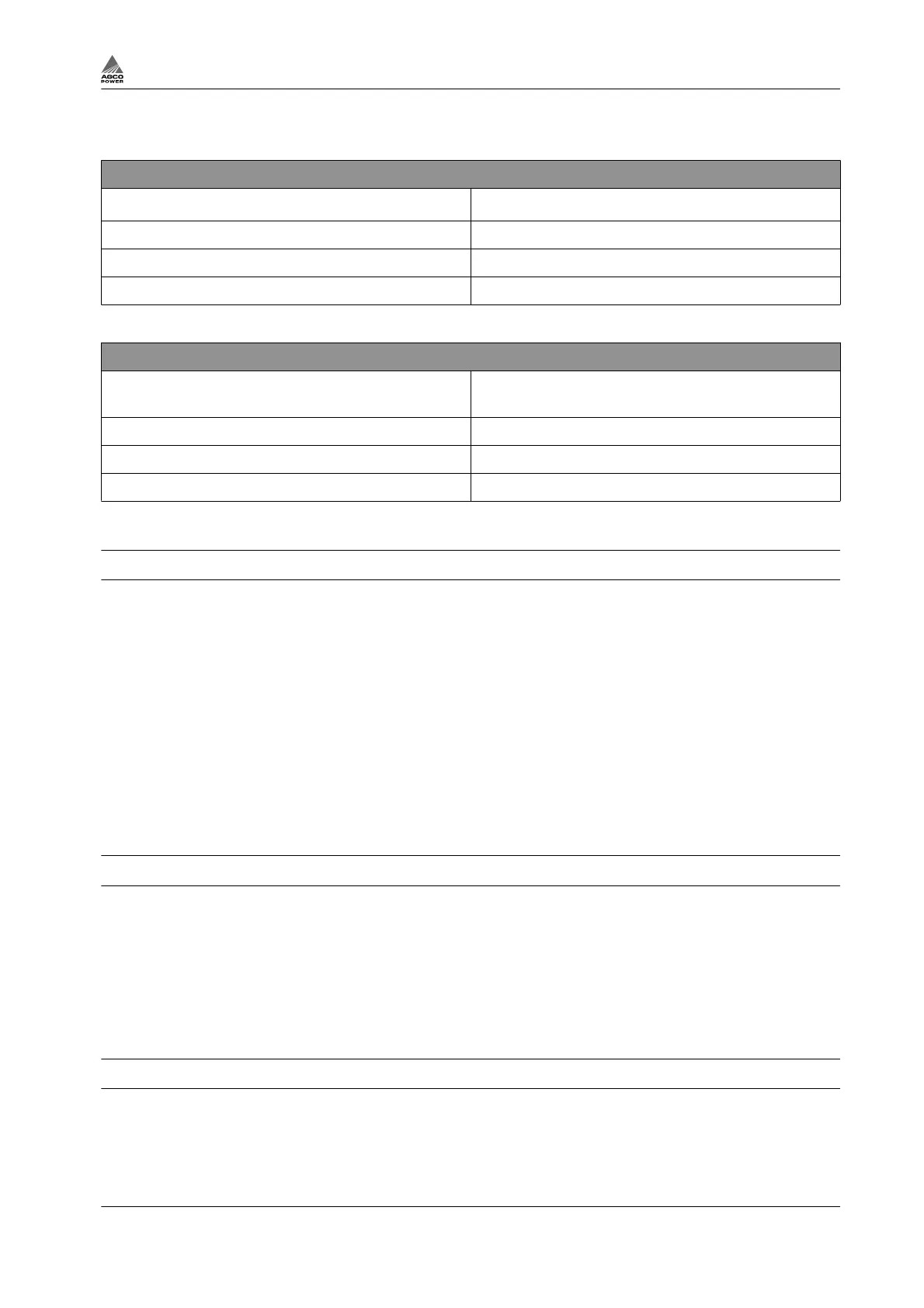

1.3.2.5 SCR system technical data

Principal data

SCR system

Bosch DENOXTRONIC 2.2

Minimum operating temperature -40 °C

Maximum DEF temperature 70 °C

Maximum SCR system temperature 80 °C

Dosing system

Reagent fluid type DIN70070/ISO22241 certified DEF (Diesel Exhaust

Fluid), e.g. AdBlue

DEF consumption Approximately 6-8% of fuel consumption

[1]

Pre-filters 100 μ

Main filter 10 μ

[1]

DEF consumption may be higher, depending on the application and load profile of the engine.

1.3.3 Cylinder block

The cylinder block is the main body of the engine, to which other engine parts are attached. Wet and

replaceable cylinder liners are supported at the middle, which reduces vibrations and directs coolant

circulation mainly to the upper part of the liners.

The seal between the lower part of the cylinder liner and the cylinder block is achieved by three O-rings.

The O-rings are fitted in grooves in the liner in 33-, 44-, 49-, 66- and 74-engines . The O-rings are fitted in

grooves in the cylinder block in 84- and 98-engines . The upper part is sealed by the cylinder head gasket.

The camshaft is located in the cylinder block.The camshaft front bearing location is fitted with a separate

bearing sleeve and the remaining bearing locations are machined directly in the cylinder block in 33-, 44-

and 49-engines. There are separate bearing sleeves in all camshaft bearing locations and the drilling for the

camshaft rear end is covered with a plug in the 66-, 74-, 84- and 98-engines.

There are spaces on both sides of the rear main bearing for guide bearing shims (the crankshaft thrust

bearings).

1.3.4 Flywheel housing

The flywheel housing is fitted at the rear end of the cylinder block. The seal for the crankshaft rear end is

placed in a bore in the housing. The starter motor fixing point is fitted in the flywheel housing.

The lower face of the flywheel housing functions as a sealing surface for the oil sump gasket. This means

that the lower face of the cylinder block must be level with the flywheel housing. When fitting the flywheel

housing, its position is determined by tension pins.

The flywheel housing is delivered according to the requirements set by the engine model and different

flywheel housings can be mounted on all engine types.

1.3.5 Valve mechanism

The valve mechanism is operated by the camshaft which is located in the cylinder block. The drive is

transferred with the help of tappets and push rods. The camshaft gear wheel is fitted with a nut and

guided with a key. Each bearing is lubricated by the force feed lubrication system through drilled oilways in

the cylinder block.

1. Introduction

4th Generation Engines 1-13

8370 79492

Loading...

Loading...