3.4 Valve mechanism

3.4.1 Reconditioning valve mechanism

Procedure

1.

Check the valve tappets, especially the contact surface against the camshaft.

Worn or damaged tappets must be discarded.

2.

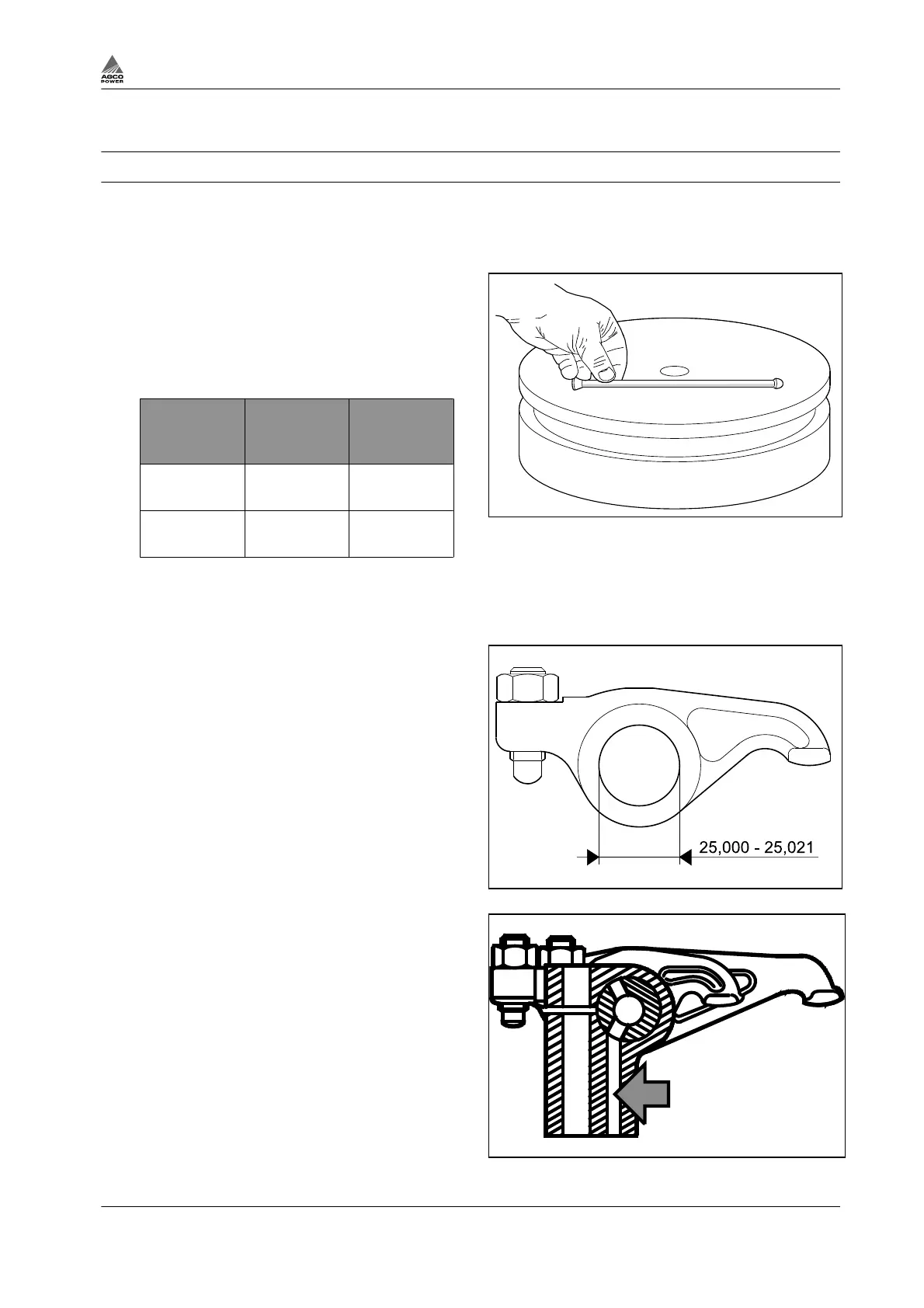

Check the straightness of the push rods by

rolling the push rods on a surface table.

a) Also check the spherical surfaces at the

ends.

b) See the length difference between the

push rods in different engine types.

Total length

of push rod

Order

number of

push rod

Engine type

245 - 246.3

mm

8370 70119 33 - 74

286 - 287.3

mm

8370 69014 84 -98

3.

Disassemble and clean the rocker arm

mechanism.

a) Check the shaft for wear.

b) Check that the oil ways are clean.

Fig. 30

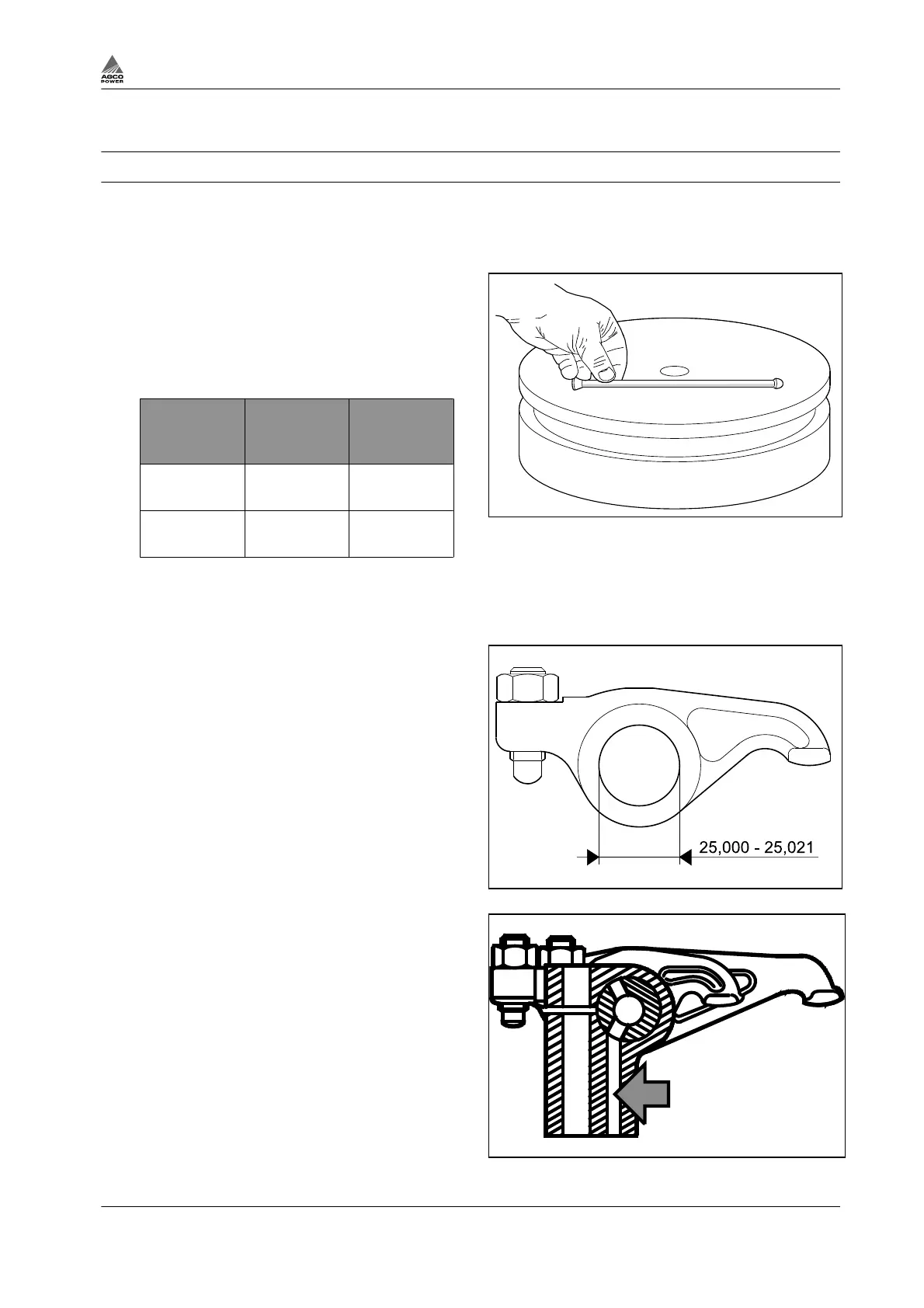

4.

Check the diameter of the rocker arm bore,

25.000 - 25.021 mm.

5.

Change the worn or damaged rocker arm.

6.

Grind the rocker arm valve contact surface to

the correct shape, where necessary.

Do not grind more than necessary, as the

hardened layer is thin.

Fig. 31

7.

Fit the plug to the other end of the rocker

arm shaft.

8.

Lubricate the shaft.

9.

Fit the parts in the correct order.

Note the correct position of the shaft and the

bearing brackets.

10.

Fit the other end plug and tighten plugs to 25

Nm.

Fig. 32

3. Maintenance

4th Generation Engines 3-21

8370 79492

Loading...

Loading...