3.5.4 Fitting crankshaft

NOTE: Bearing shells must never be reamed or machined in any other way. Do not file the sides of the

bearing caps either.

Procedure

1.

Clean the oilways, bearing shells and bearing locations.

2.

Check that the crankshaft is clean.

3.

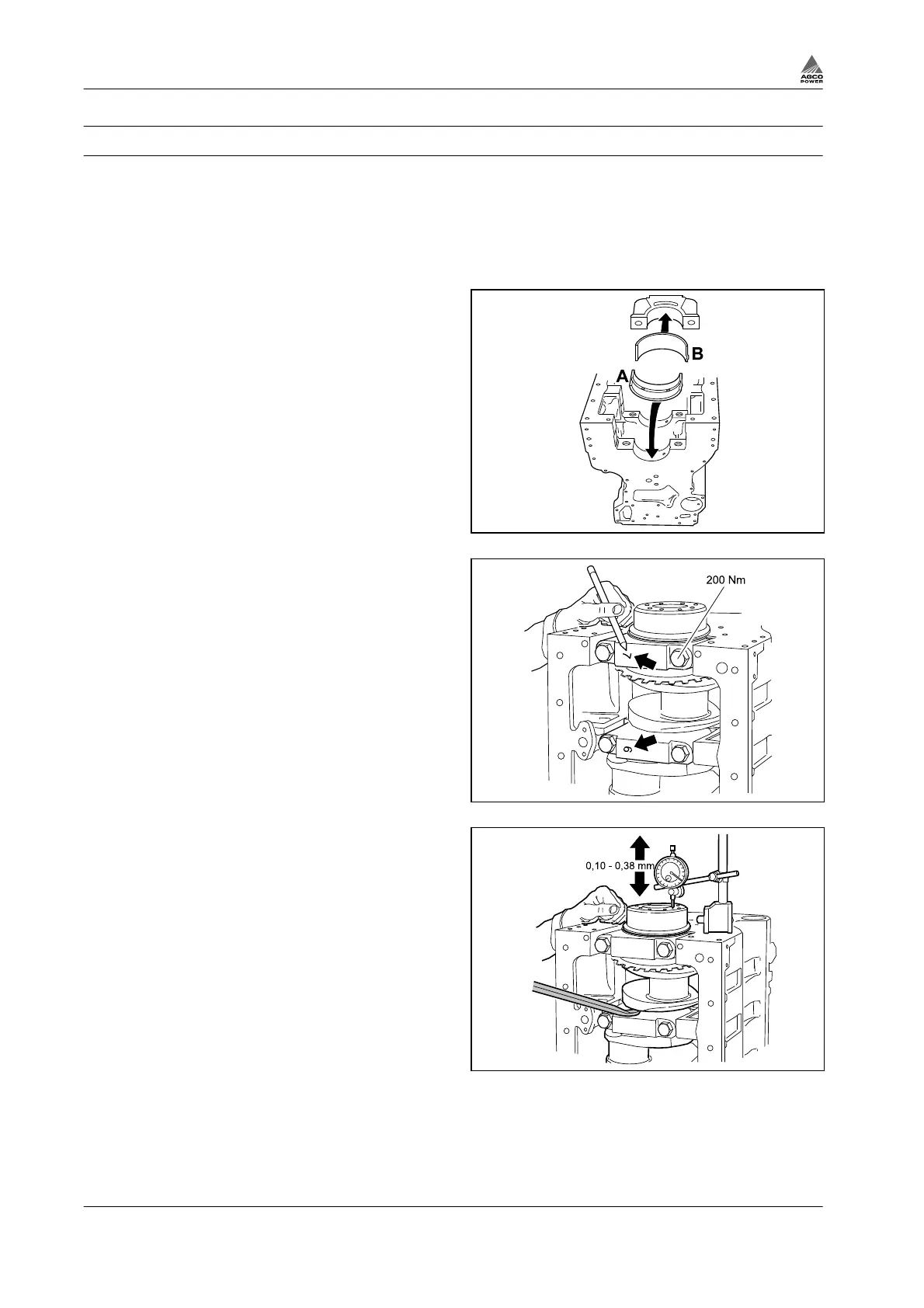

Assemble the bearing with oil holes/groove

(A) to the cylinder block and the bearing with

no hole (B) to the bearing cap.

a) Make sure that the bearing shell clamping

claws fit into their notches.

b) Make also sure that the shells to be fitted

in the cylinder block have a hole

coinciding with the oil port.

4.

Lubricate the bearing surfaces and fit the

crankshaft.

5.

Fit the crankshaft thrust bearings with the

lubricating grooves facing the crankshaft.

Fig. 41

6.

Fit the main bearing caps according to their

numbering.

Bearing lock in the block and in the cap are

on the same side.

The rear thrust bearings are supplied with

guide lugs.

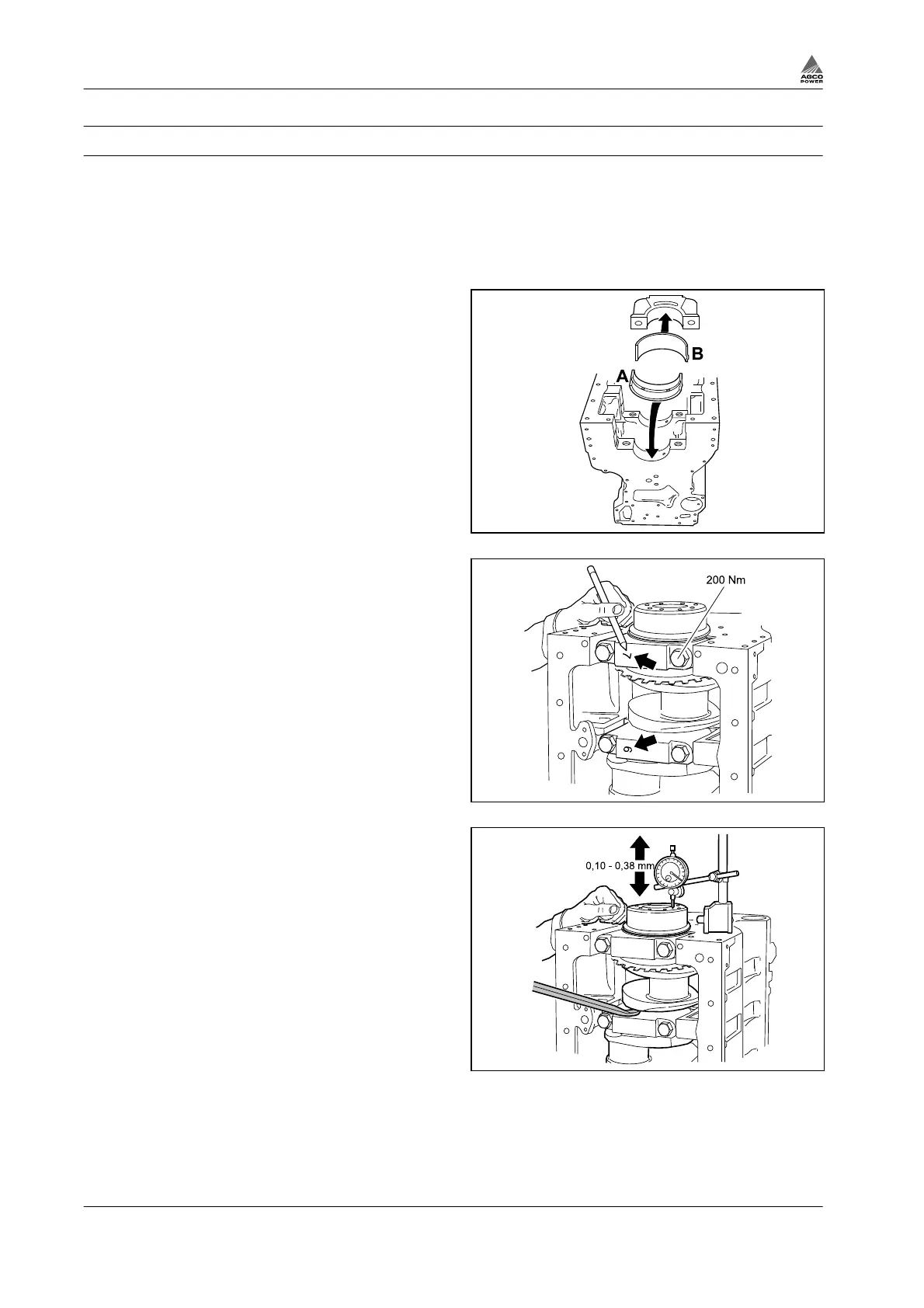

7.

Lubricate the bolts and tighten them to 200

Nm.

Fig. 42

8.

Check that the crankshaft can rotate without

binding.

9.

Check the end float using a dial gauge.

The correct end float is 0.10 - 0.38 mm.

10.

Fit oversize thrust bearings, if the end float is

too large.

Fig. 43

3. Maintenance

3-28 4th Generation Engines

8370 79492

Loading...

Loading...