3.1.4 Changing camshaft bushing (33-49 engines)

Procedure

1.

Remove the bushing with an internal puller,

for example SYKES 854.

If the camshaft rear end plug is removed, the

bushing can be forced out with a long drift.

2.

Clean the bushing location carefully.

3.

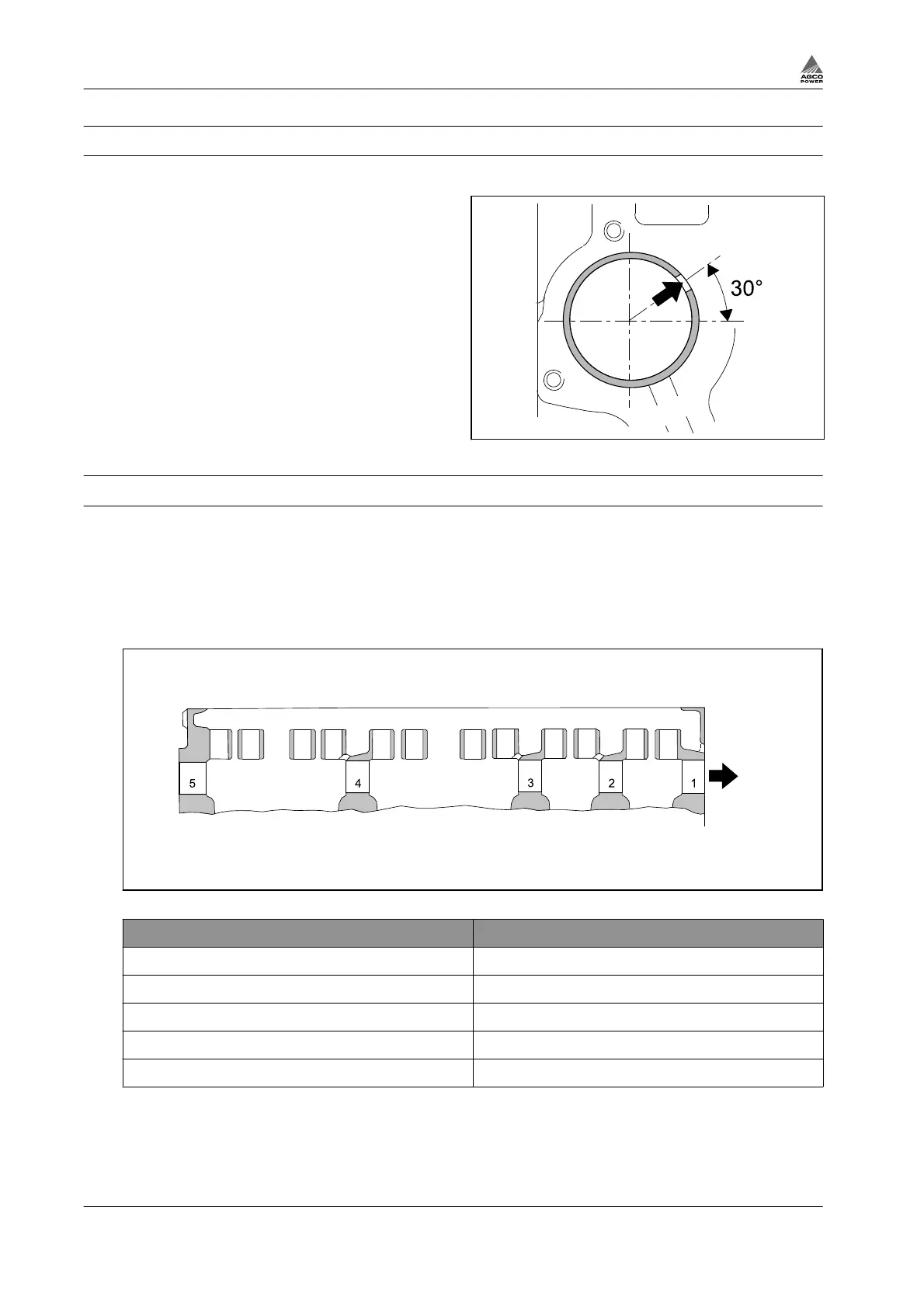

Fit the oil hole of the bushing at a 30° angle

from horizontal level.

It is not necessary to ream the bushing,

because the bushing has a correct inner

diameter when the bushing is fitted in

position.

Fig. 3

3.1.5 Changing camshaft bushing (66-98 engines)

All camshaft bearing points are supplied with a separate bearing bushing.

Procedure

1.

Remove the camshaft rear end plug and tap the bushings out with a long drift.

Look for the different outer diameters when removing.

2.

Clean the bushing locations carefully.

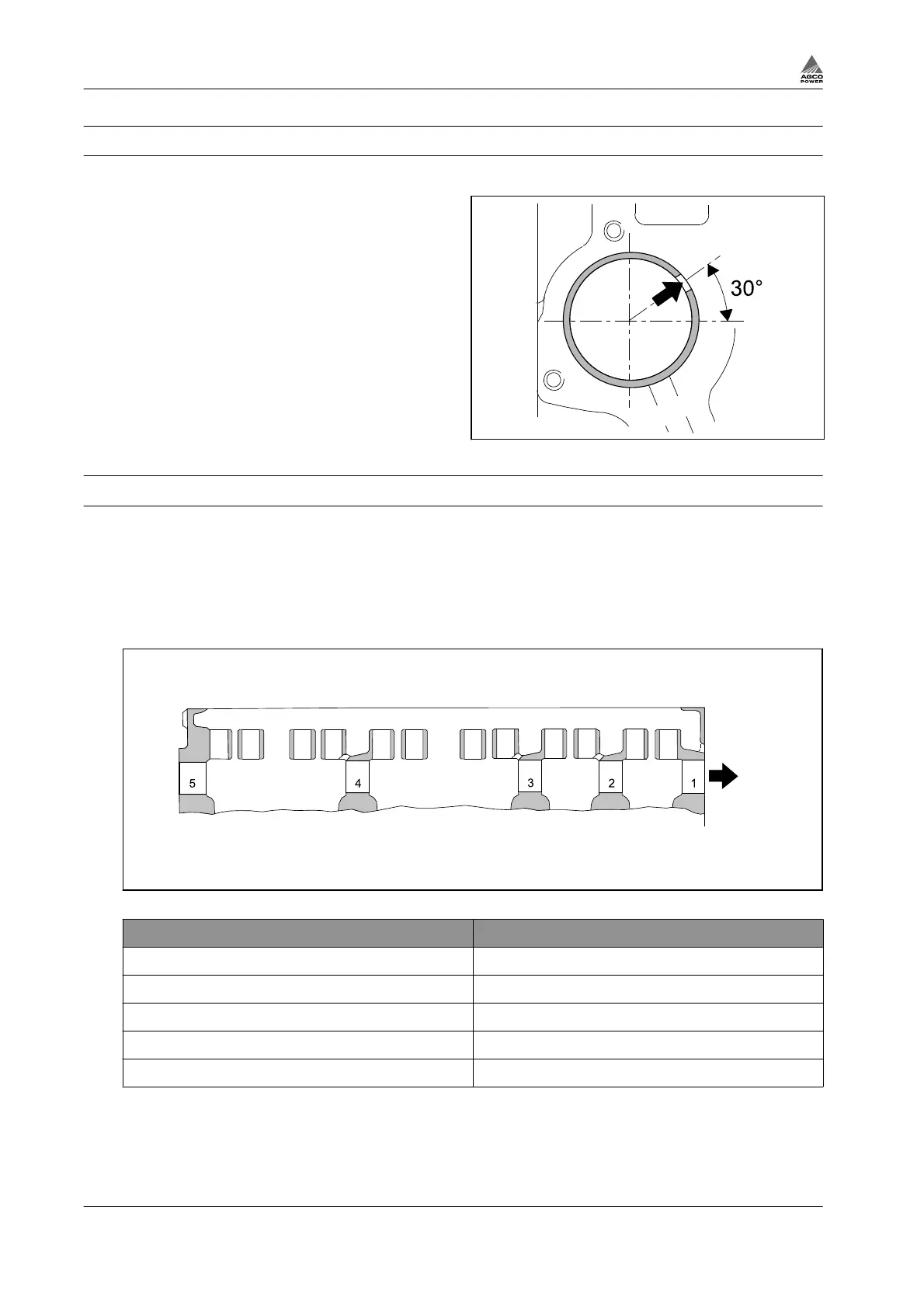

Fig. 4 Hole diameters for the bushings. Numbering begins from the front end of the engine.

Hole 66, 74 and 84 engines Hole diameter

1 55.62 - 55.65 mm

2 55.42 - 55.45 mm

3 55.22 - 55.25 mm

4 55.42 - 55.45 mm

5 55.64 - 55.67 mm

3. Maintenance

3-6 4th Generation Engines

8370 79492

Loading...

Loading...