4.

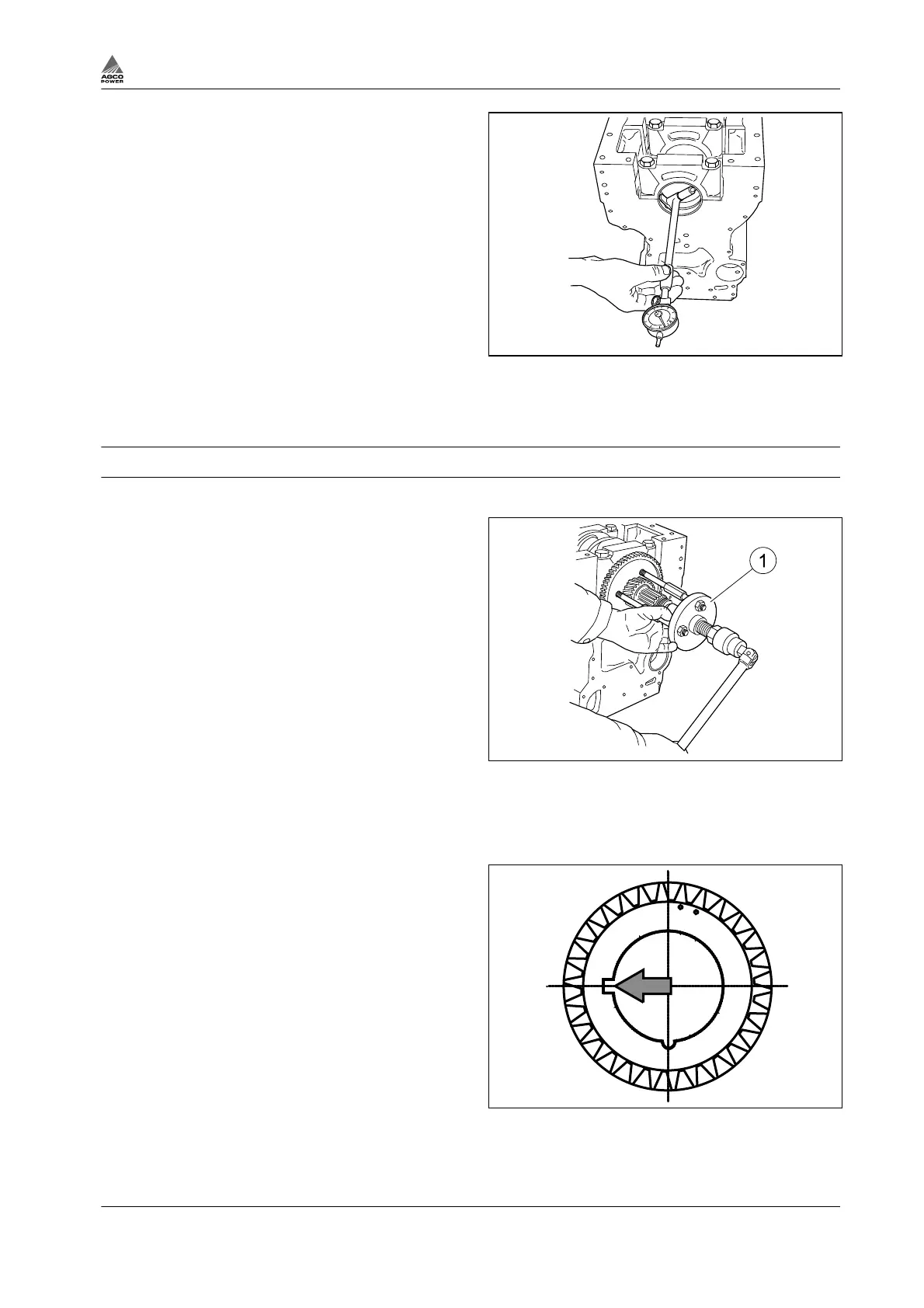

Measure the I.D. with a dial gauge which has

been zeroed to the dimensions given in point

2.

With this method the indicator shows the

actual bearing clearance.

Measure at several points in case the worn

bearing housing is not round.

5.

Grind the bearing journals on the crankshaft,

if needed.

The maximum bearing clearance for main

bearings is 0.18 mm and 0.14 mm for

connecting rod big-end bearings with new

bearing shells.

Refer to the specifications for the correct

undersize and the corresponding bearings.

Fig. 38

3.5.3 Changing crankshaft gears

Procedure

1.

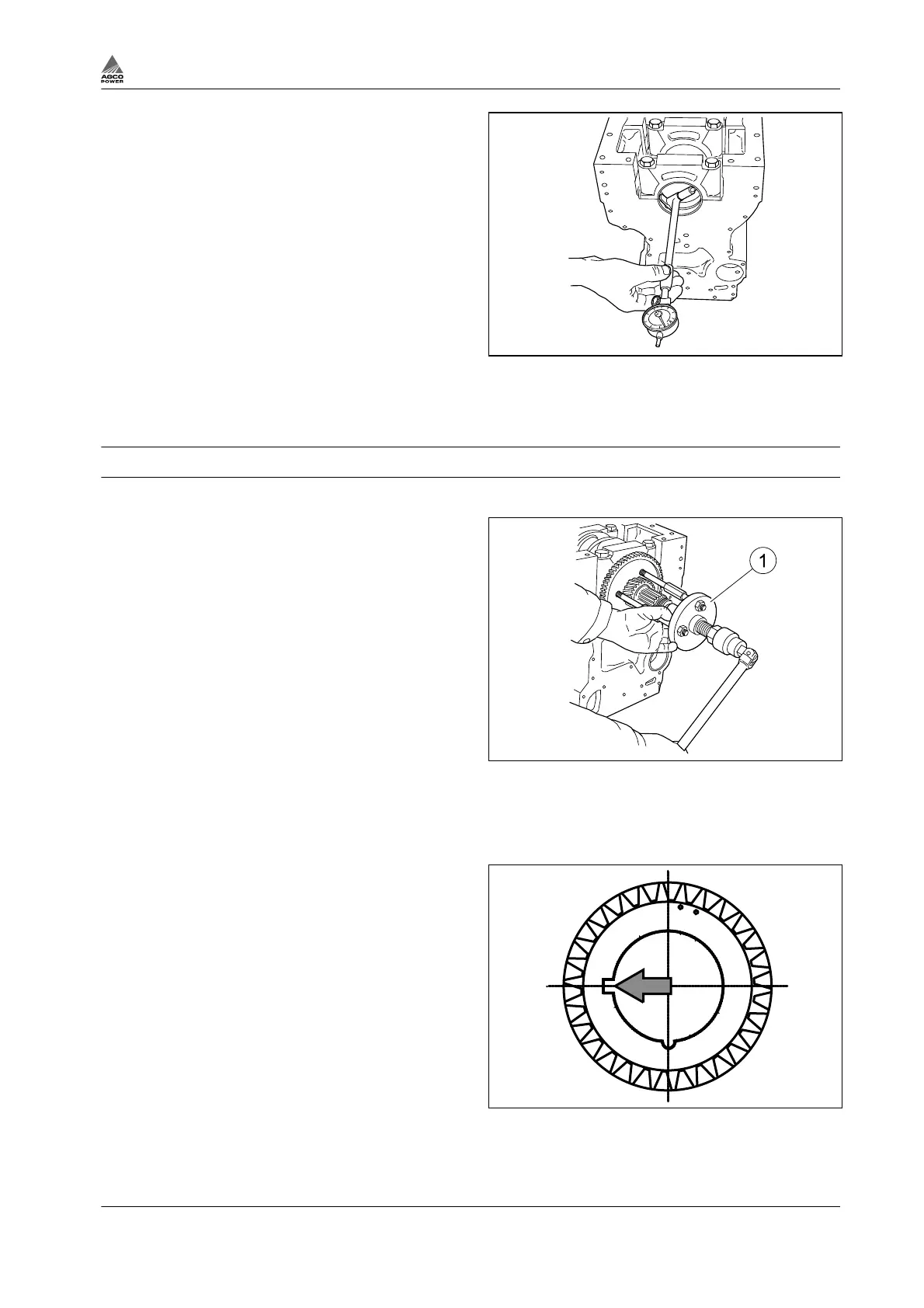

Apply puller 9052 48800 to the crankshaft

gears and pull off both gears.

2.

98-engine: Break the crankshaft gears using

for example a grinder.

a) Grind the gears enough for breaking.

b) Hit the gears apart with a chisel.

c) Do not damage the crankshaft!

Fig. 39

(1) Puller 9052 48800

3.

Clean the seat on the crankshaft for example with a wire brush.

4.

Heat the new gears to 220 - 250°C.

5.

Assemble the gears onto the shaft.

a) Note the position of the key and make

sure that the aligning marks on the front

gear are visible.

b) Set the crankshaft key into the angular

key slot.

6.

Let the gears cool.

Fig. 40

3. Maintenance

4th Generation Engines 3-27

8370 79492

Loading...

Loading...