3.13 Fuel system

3.13.1 Bleeding the fuel system

WARNING:

Do not make any work at the common rail high pressure fuel system when the engine is

running. Wait at least 30 seconds after stopping the engine .The first high pressure

component has to be loosened slowly, so that the pressure inside the fuel system can

adjust to ambient pressure. If the jet of high pressure fuel contacts your skin, fuel

penetrates the skin causing severe injuries. Get medical help immediately!

Procedure

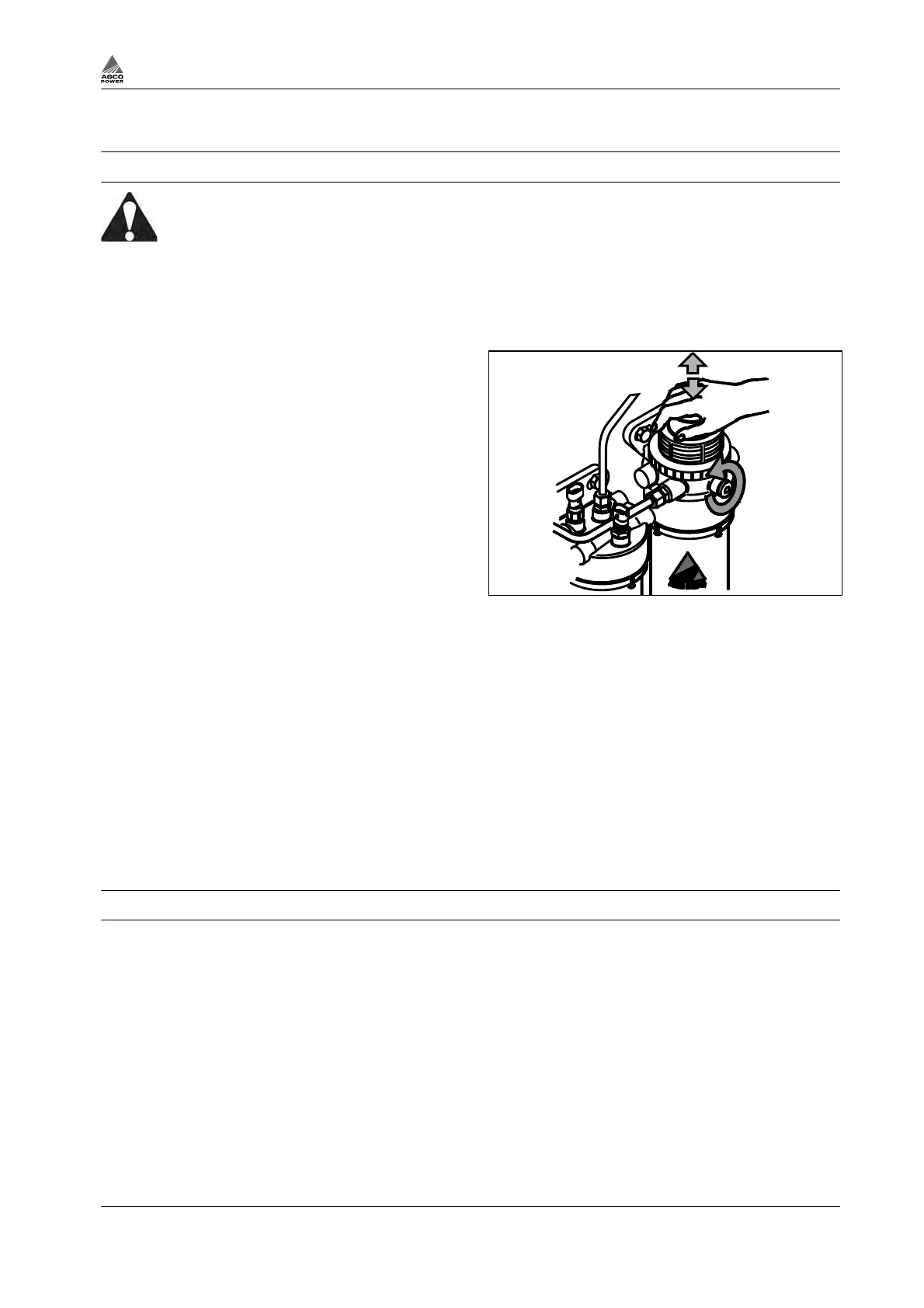

1.

Open the bleeding plug on the pre-filter

bracket.

2.

Put a transparent hose in the plug hole and

lead it into a suitable container.

3.

Pump fuel with the hand pump on top of the

pre-filter.

4.

Pump with the hand pump until there are no

air bubbles in the fuel stream.

5.

Remove the hose and turn in the bleeding

plug.

6.

Clean the engine of eventual overspill fuel.

Fig. 102

7.

Start the engine. The fuel system removes automatically the air left in the system.

NOTE: Do not use the hand pump when the engine is running. Do not use any tools or excessive

force on the pre-filter hand pump.

NOTE: The fuel system is equipped with a pressure sensor that alarms before interference has

developed. Reasons can be for instance:

• Empty fuel tank.

• Clogged fuel filters.

• Suction piping clogged or leaking air.

• Unsuitable fuel (e.g. summer fuel in the winter).

NOTE: Use of spirits as antifreeze is not useful or recommended at all. It makes the fuel solidify and

weakens the lubricating qualities of the fuel and increases the possibility of corrosion.

3.13.2 Measuring fuel feed pressure

Procedure

1.

Clean the pre-filter, the fuel filter and the related fuel pipes from the outside.

3. Maintenance

4th Generation Engines 3-61

8370 79492

Loading...

Loading...