3.6 Connecting rods and pistons

3.6.1 Removing pistons together with connecting rods

Procedure

1.

Remove the oil sump and the oil inlet and pressure pipes.

2.

Remove the cylinder head.

3.

Scrape off any soot in the cylinder liner. If the turning edge is clearly marked, smooth it down

carefully with a scraper.

4.

Remove the big-end bearing caps and bearing shells. Place the shells in order if they are to be re-

used.

5.

Push up the piston and connecting rod with the shaft of a hammer or similar wooden tool.

6.

Remove the piston pin snap rings. Push out the pin.

NOTE: If the piston pin does not move under thumb pressure, the piston should be heated to 100°C.

3.6.2 Changing connecting rod bearings

3.6.2.1 Piston pin bushing

Procedure

1.

Clean the connecting rod and bearing shells.

2.

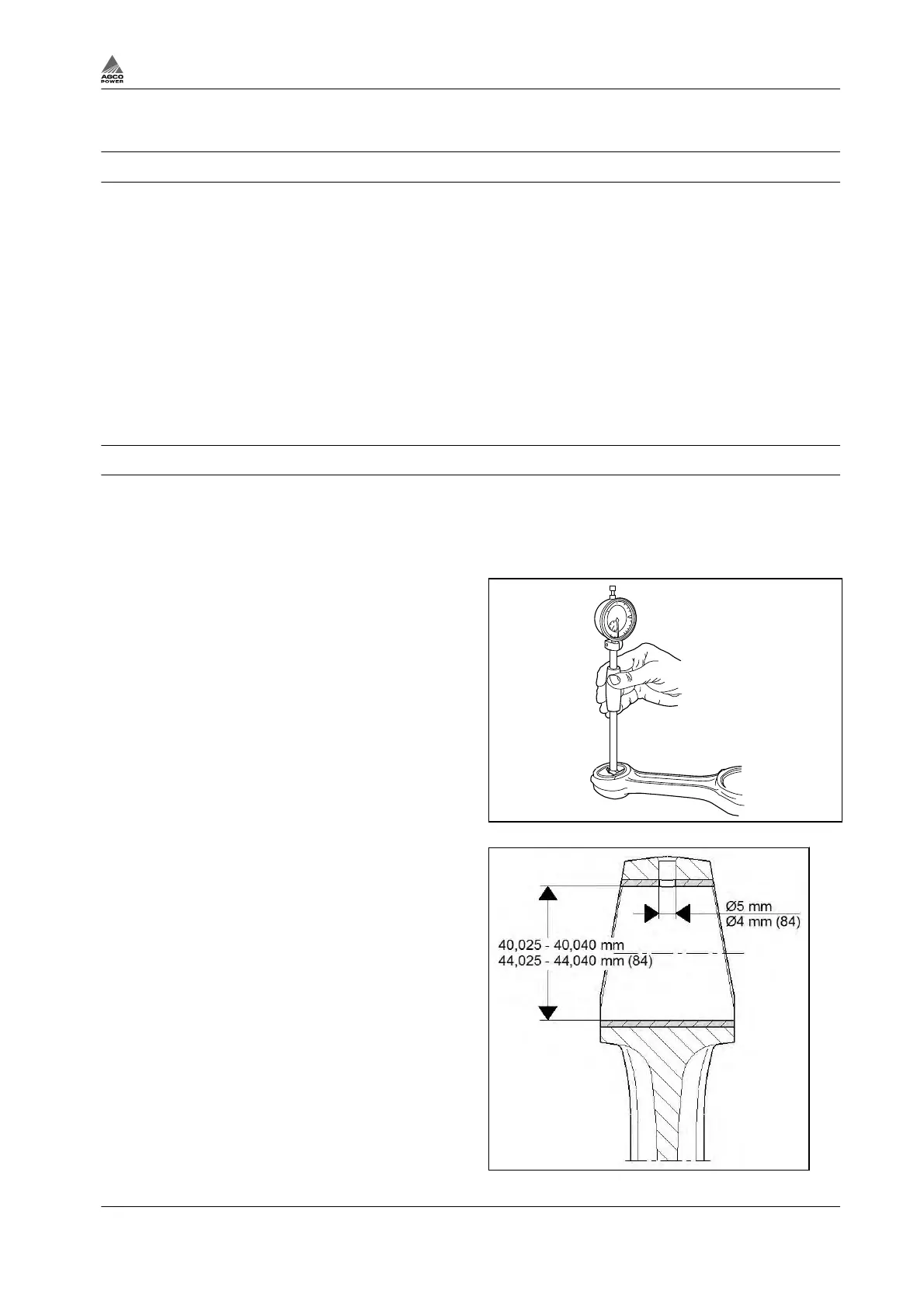

Measure the I.D. of the piston pin bushing

using a cylinder gauge.

3.

Drive the piston pin bushing out using a drift,

if the piston pin bushing is worn.

4.

Press the new piston pin bushing in position.

Fig. 48

5.

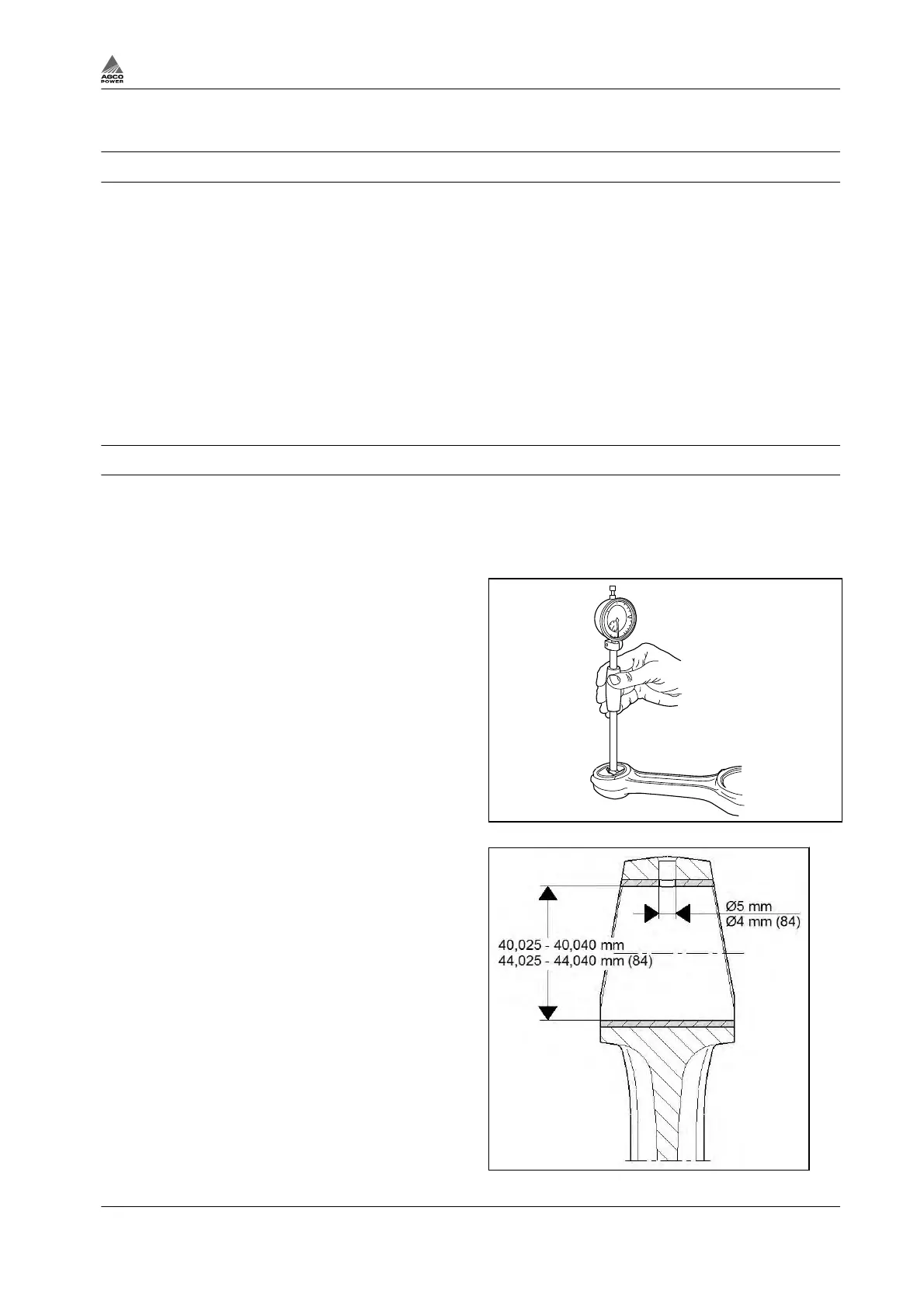

Make sure that the oil hole in the piston pin

bushing coincides with the respective hole in

the connecting rod by size and location.

a) 33-74 engines: Cut and ream the piston

pin bushing to obtain correct shape and

diameter.

b) 84-98 engines: Ream the piston pin

bushing to obtain correct diameter.

NOTE: The connecting rod can, if needed, be

fitted with a 0.5 mm oversize bushing.

Fig. 49

3. Maintenance

4th Generation Engines 3-31

8370 79492

Loading...

Loading...