2.

Check for cracks and other damage.

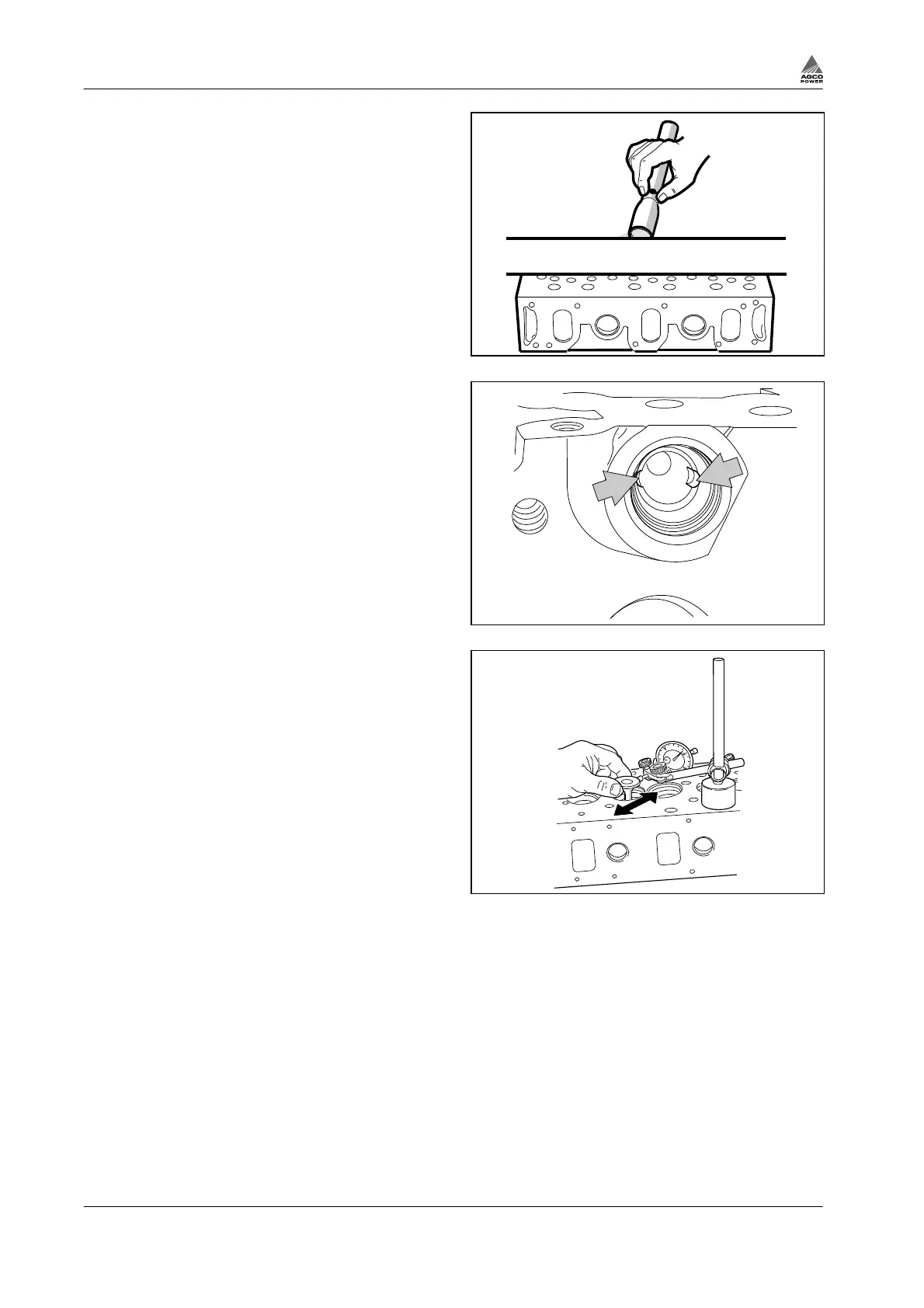

3.

Check the flatness of the cylinder head

against a straight edge.

• An uneven or warped surface need to be

surface ground.

• The height of the cylinder head, after

grinding, can not be less than 109.50 mm.

• The valve disc depth from the cylinder

head surface must be 0.60 mm for the

exhaust valves and 0.80 mm for the inlet

valves.

Fig. 18

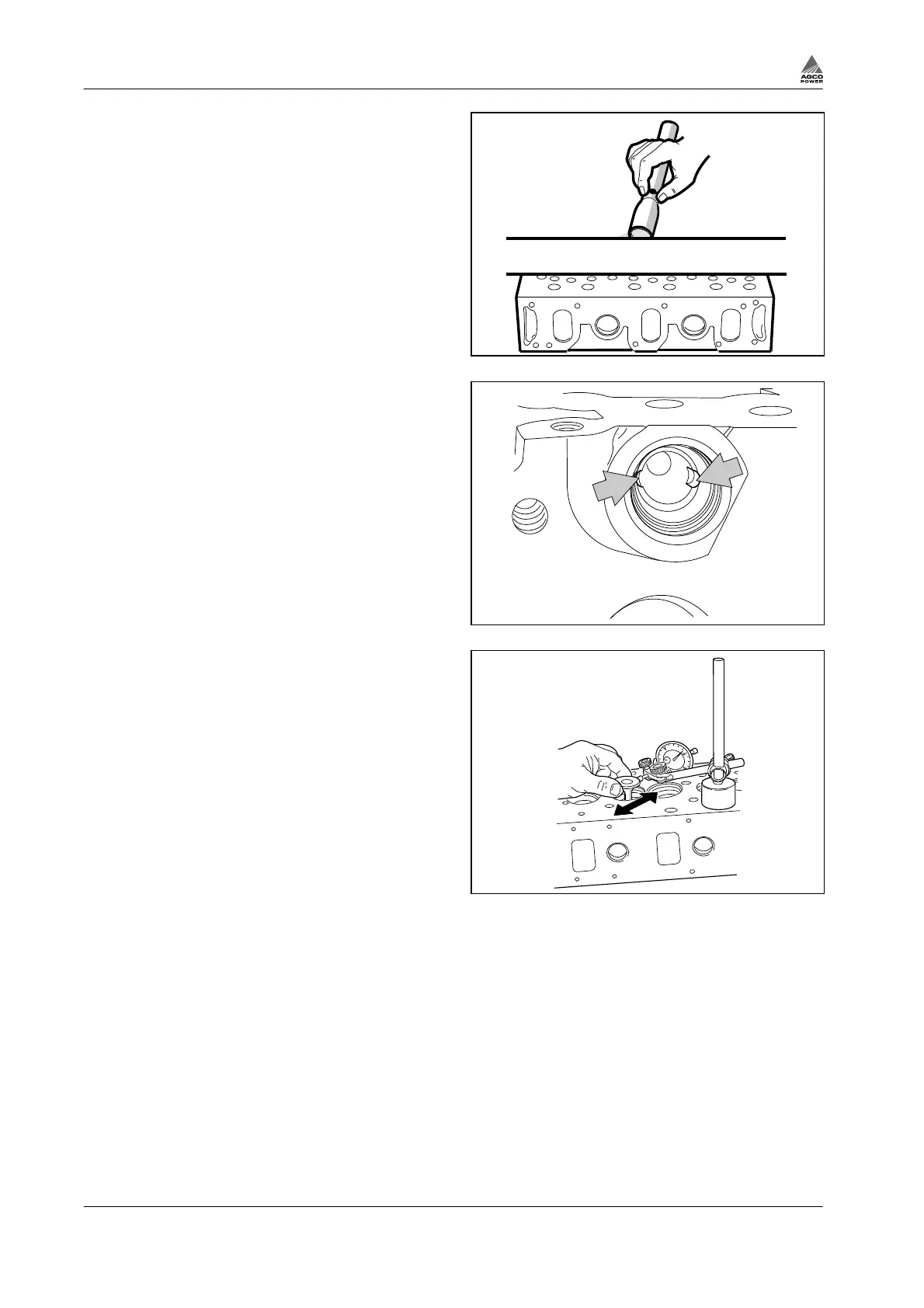

4.

Straighten and clean the injector location

seat in the cylinder head with cutter 9120

85400.

5.

Check that the location for the side feed pipe

is clean, especially the grooves for the guide

balls.

Fig. 19

6.

Measure the clearance between the valve

stem and the valve guide with a dial gauge.

a) Lift the valve so that the valve head is 15

mm from the face of the cylinder head,

and measure the clearance.

The clearance must not be greater than

0.30 mm for the inlet valves and 0.35 mm

for the exhaust valves.

b) Use a new valve when measuring, in

order to find out the valve guide wear.

Fig. 20

3. Maintenance

3-16 4th Generation Engines

8370 79492

Loading...

Loading...