ZA-V BAG0087.11

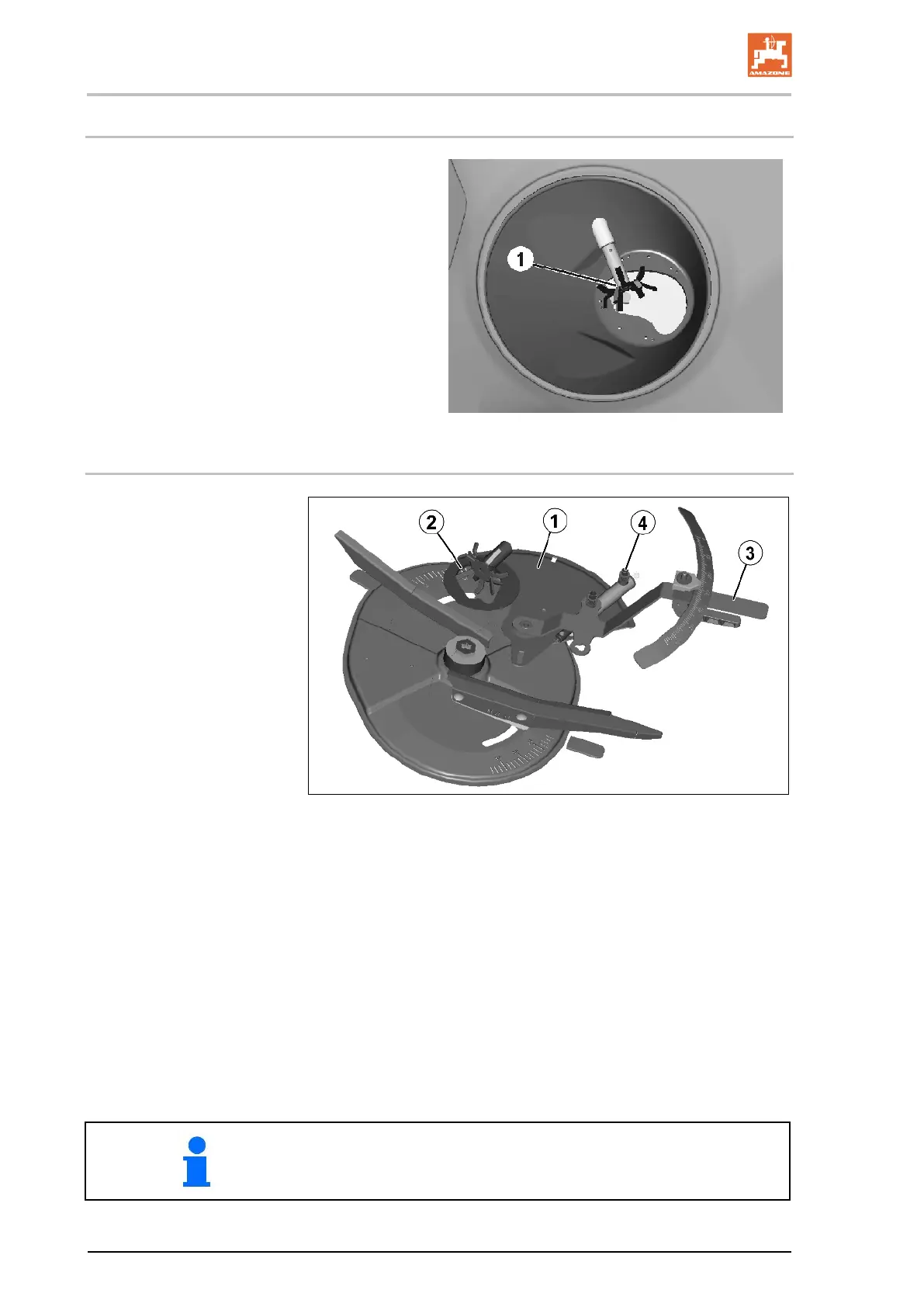

5.4 Agitator

The spiral agitators (Fig. 14/1) in the hopper tips

ensure uniform fertiliser flow to the spreading

discs. The slow-rotating, spiral-

of the agitator carry the fertiliser evenly to the

corresponding outlet opening.

The PTO shaft is responsible for the drive. The

speed reduction is attained by means of a free-

wheel.

14

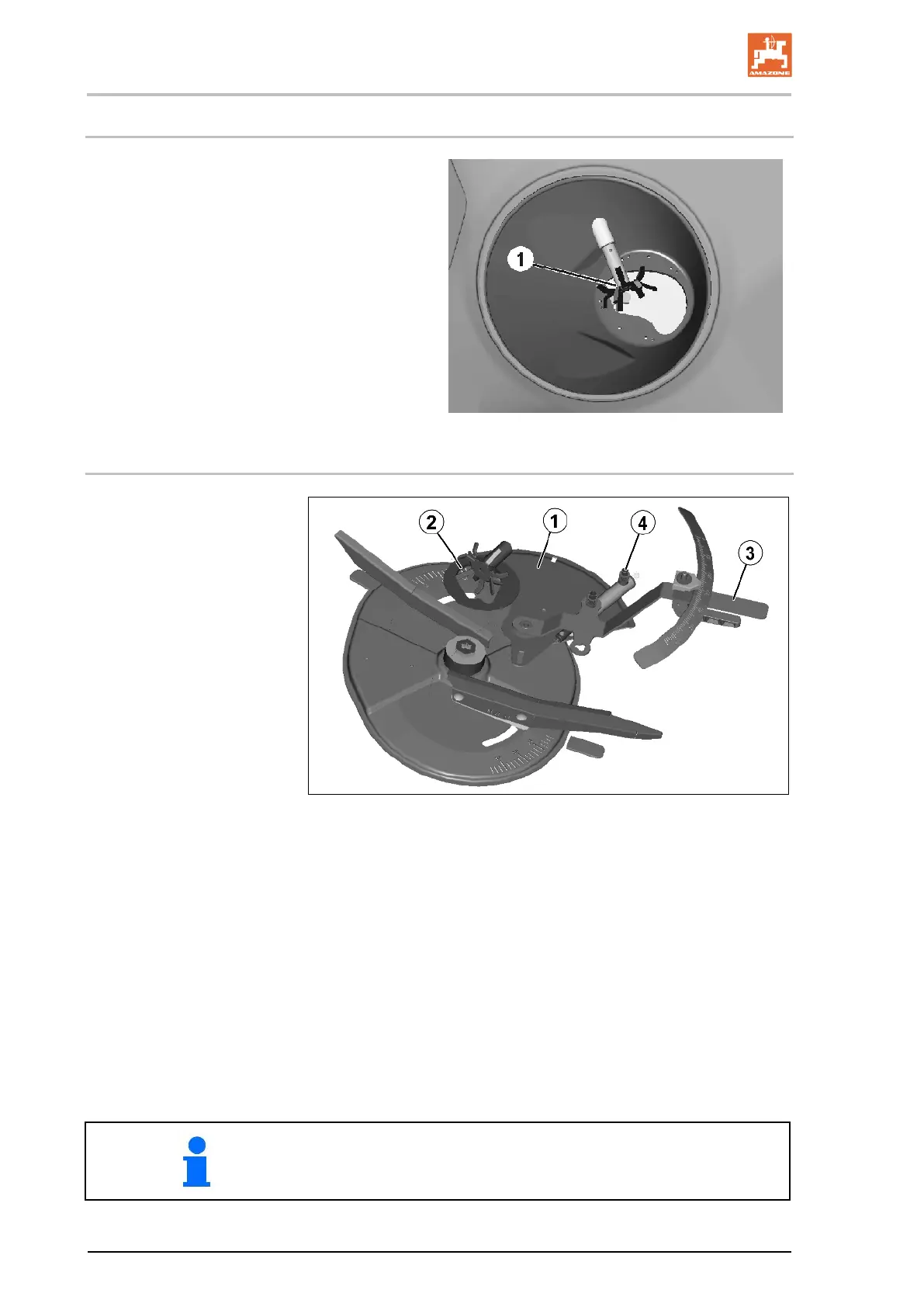

5.5 Dosing slider

Fig. 15

electronically with the control terminal.

In this case, dosing sliders (Fig. 15/2) operated by setting mo-

tors (Fig. 15/1) release a range of different diameters at the out-

let openings (Fig. 15/3).

The electrically shut metering shutter closes the outlet opening

in the tank.

• Manually using the setting lever (Fig. 15

/3) by adjusting different

opening widths of the outlet opening (Fig. 15/2). The required

shutter position in each case is determined either according to

the setting chart or using the sliding ruler.

The metering shutter is actuated hydraulically to open and close

the outlet opening (Fig. 15/4).

As the spreading properties of the fertiliser are subject to considera-

ble fluctuations, it is recommended that a spread rate check be car-

ried out for the selected slider position.

Loading...

Loading...