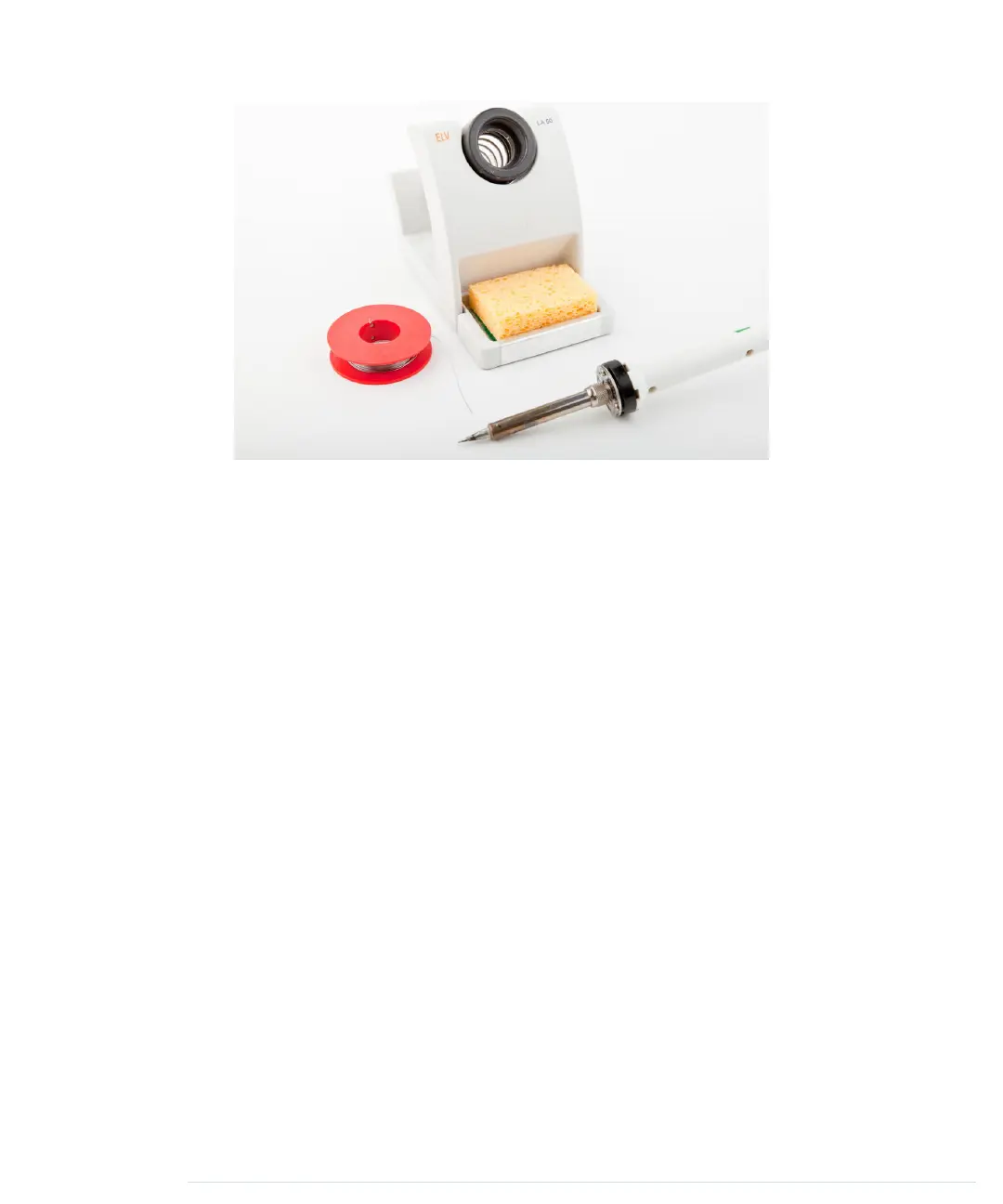

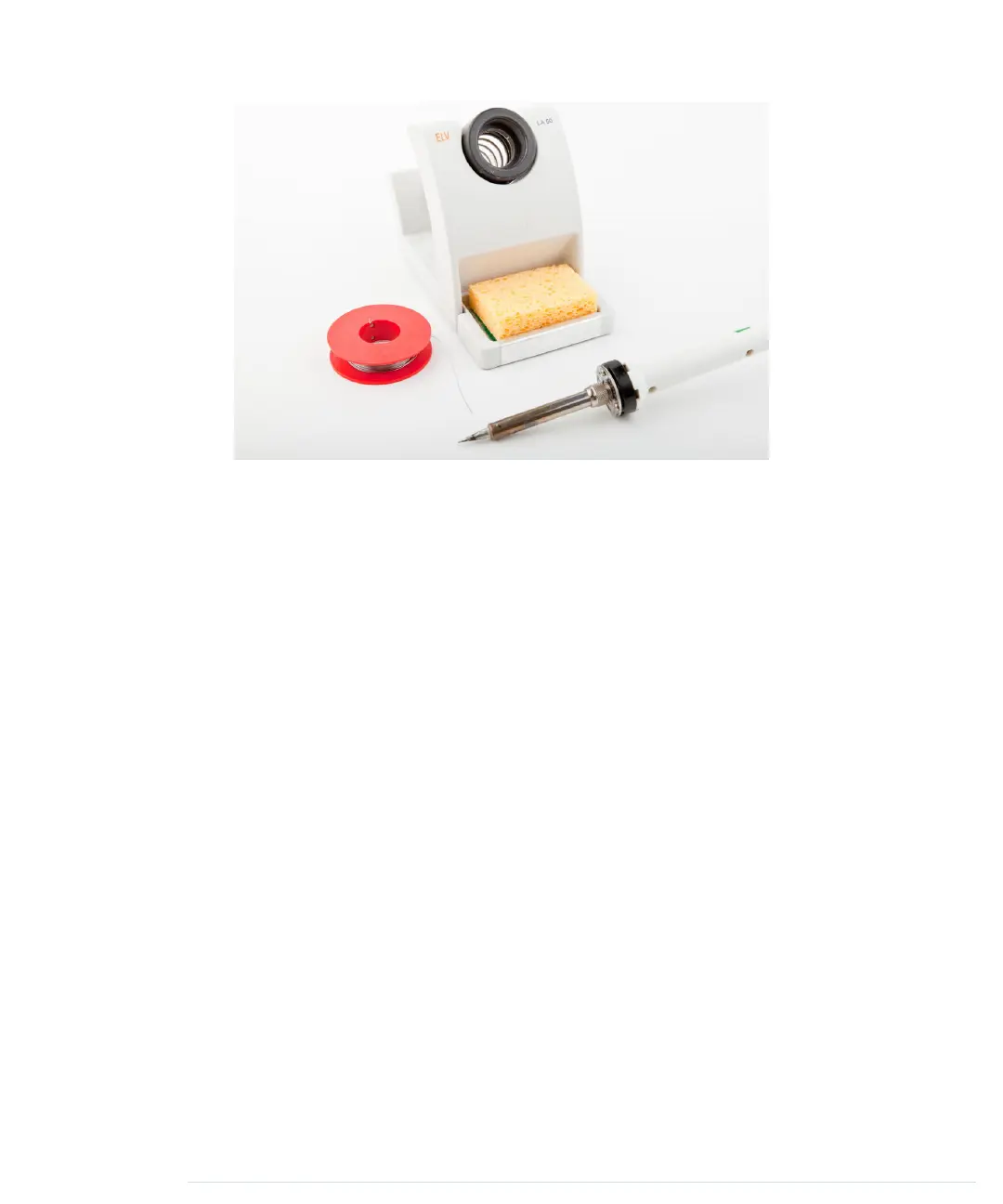

• A 25–30W soldering iron with a tip (preferably 1/16-inch) and a soldering

stand.

• A standard 60/40 solder (rosin-core) spool for electronics work. It should

have a 0.031-inch diameter.

• A sponge.

Before you start to solder, prepare your work area. Make sure you can easily

access all your tools and that you have something to protect your work area

from drops of solder. Wearing safety glasses is always a good idea! Even

seemingly simple and harmless activities such as cutting wires can be very

dangerous! Also make sure that your room has good ventilation, because the

solder fumes aren’t good for your health.

Bring all parts into the correct position: attach the pin header to the breakout

board, and make sure you can’t accidentally move it while soldering.

People get very creative when it comes to locking parts into a certain position.

But you have to be careful—don’t use flammable materials to bring parts

together. You also shouldn’t use parts that distribute heat very well, especially

if they’re in touch with other parts. Duct tape might work in some cases, but

be careful with it, too.

Try to find a piece of wood or something similar that has the right height: the

height of the pin headers. Then you can put the breakout board on top of it

and attach the pin headers. If you’re planning to solder more often and build

some electronics projects, you should always look for these little tools that

make your life easier.

Appendix 1. Electronics and Soldering Basics • 244

report erratum • discuss

www.it-ebooks.info

Loading...

Loading...