T1689 Technical Manual Rev 07 Appendix C: Recommended Torque Settings

MV3000 Air Cooled DELTA Scope

Page 183

12. APPENDIX C: RECOMMENDED TORQUE SETTINGS

12.1 SCOPE

This document details the recommended tightening torque settings for electrical and mechanical connections

to DELTA modules.

The recommended torque settings are applicable to high-tensile steel (Grade 8.8) fasteners fitted with a single

turn spring washer under the nut, and with the threads being zinc plated, passivated and unlubricated, over the

normal operating temperature of these components.

Specifically excluded are:

fasteners with any other material (e.g. brass);

fasteners with any other finish (e.g. raw steel, cadmium plated, lubrication of any sort);

slotted holes in either steel or copper.

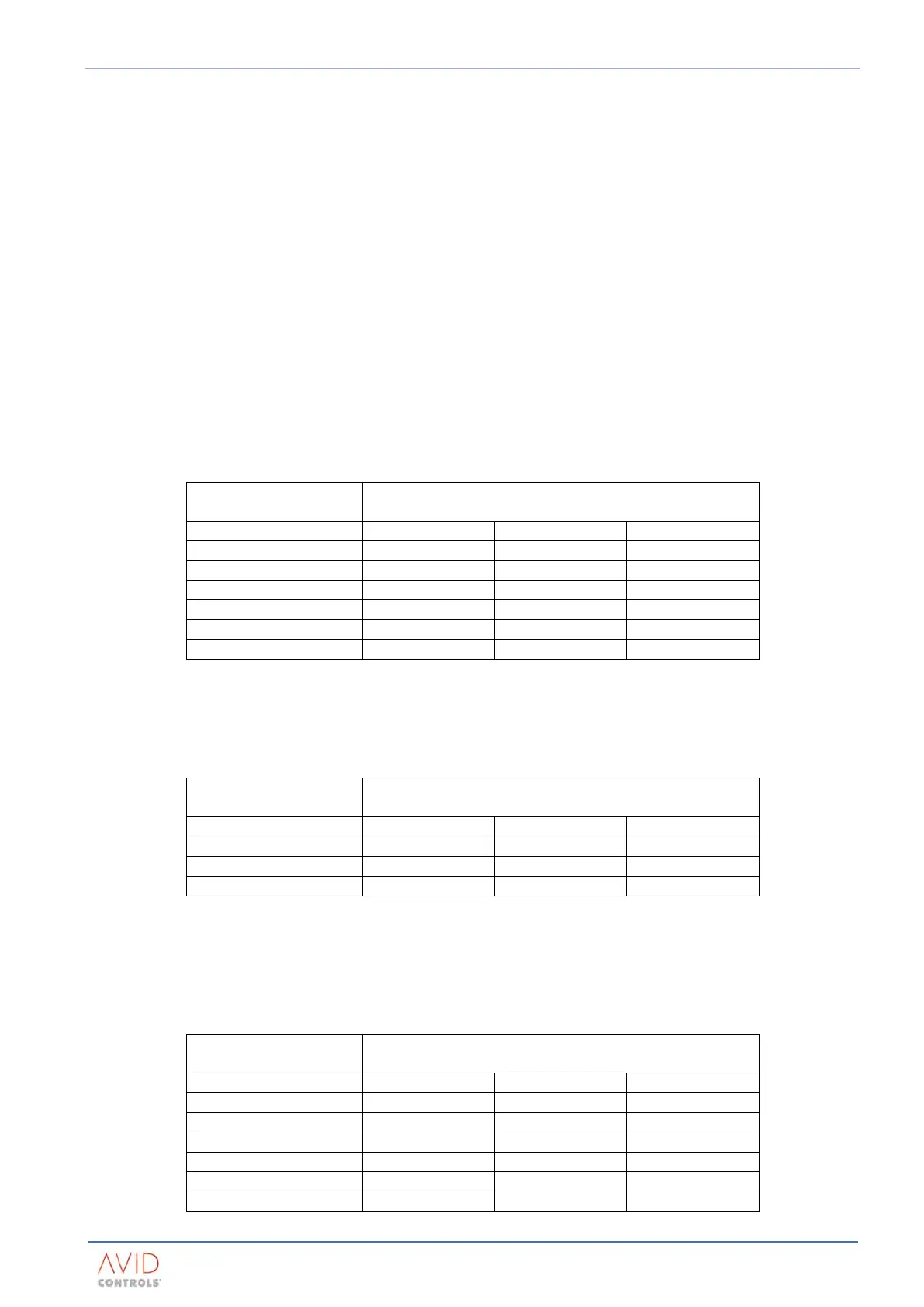

12.2 TORQUE SETTINGS FOR ELECTRICAL CONNECTIONS

The figures included in Table 12–1 are for electrical connections of copper conductor crimps to device

terminals and to all copperwork except busbars, for which figures are included in Table 12–2.

Fastener Size

Carbon Steel (8.8)

Table 12–1. – Torque Settings for Electrical Connections

12.3 TORQUE SETTINGS FOR BUSBAR JOINTS

The figures in Table 12–2 are for all busbar joints on copperwork.

Fastener Size

Carbon Steel (8.8)

Table 12–2. – Torque Settings for Busbar Joints

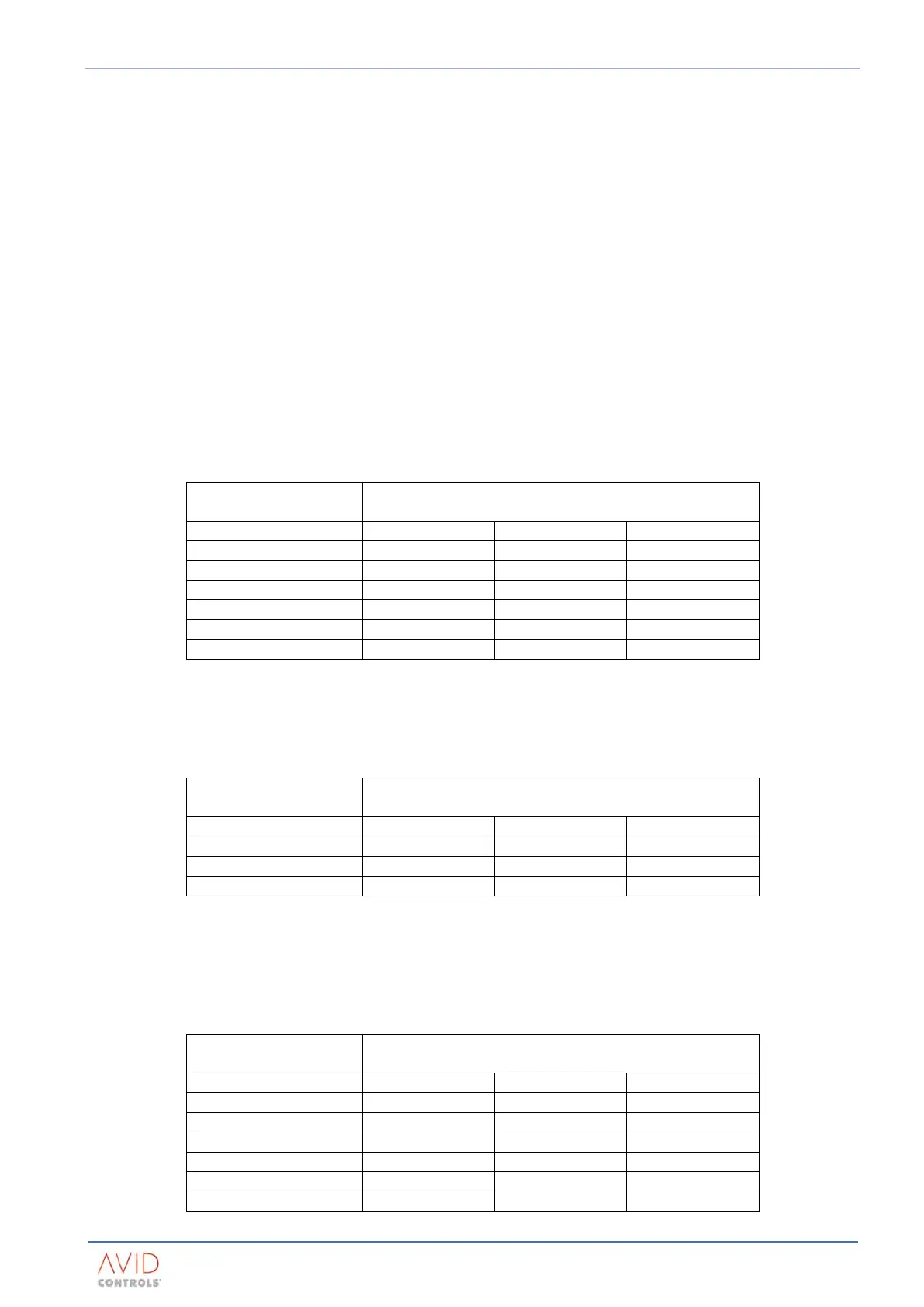

12.4 TORQUE SETTINGS FOR MECHANICAL CONNECTIONS

The figures in Table 12–3 are for the assembly and mounting of steel parts where specific electrical connection,

other than continuity, is not involved.

Fastener Size

Carbon Steel (8.8)

Table 12–3. – Torque Settings for Mechanical Connections

Loading...

Loading...