T1689 Technical Manual Rev 07 Drive (CDM) Design

MV3000 Air Cooled DELTA Overview of Components Required

Page 79

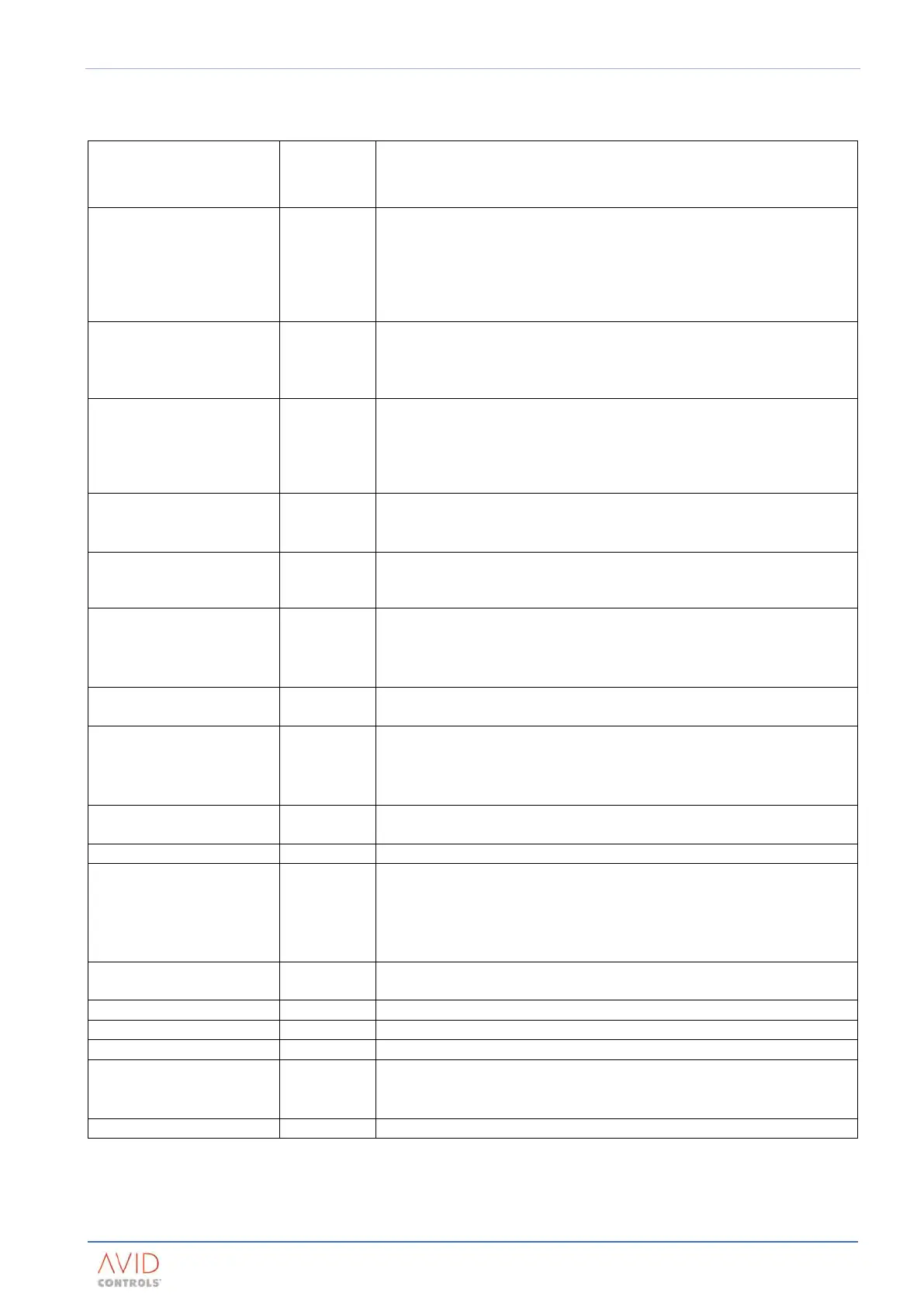

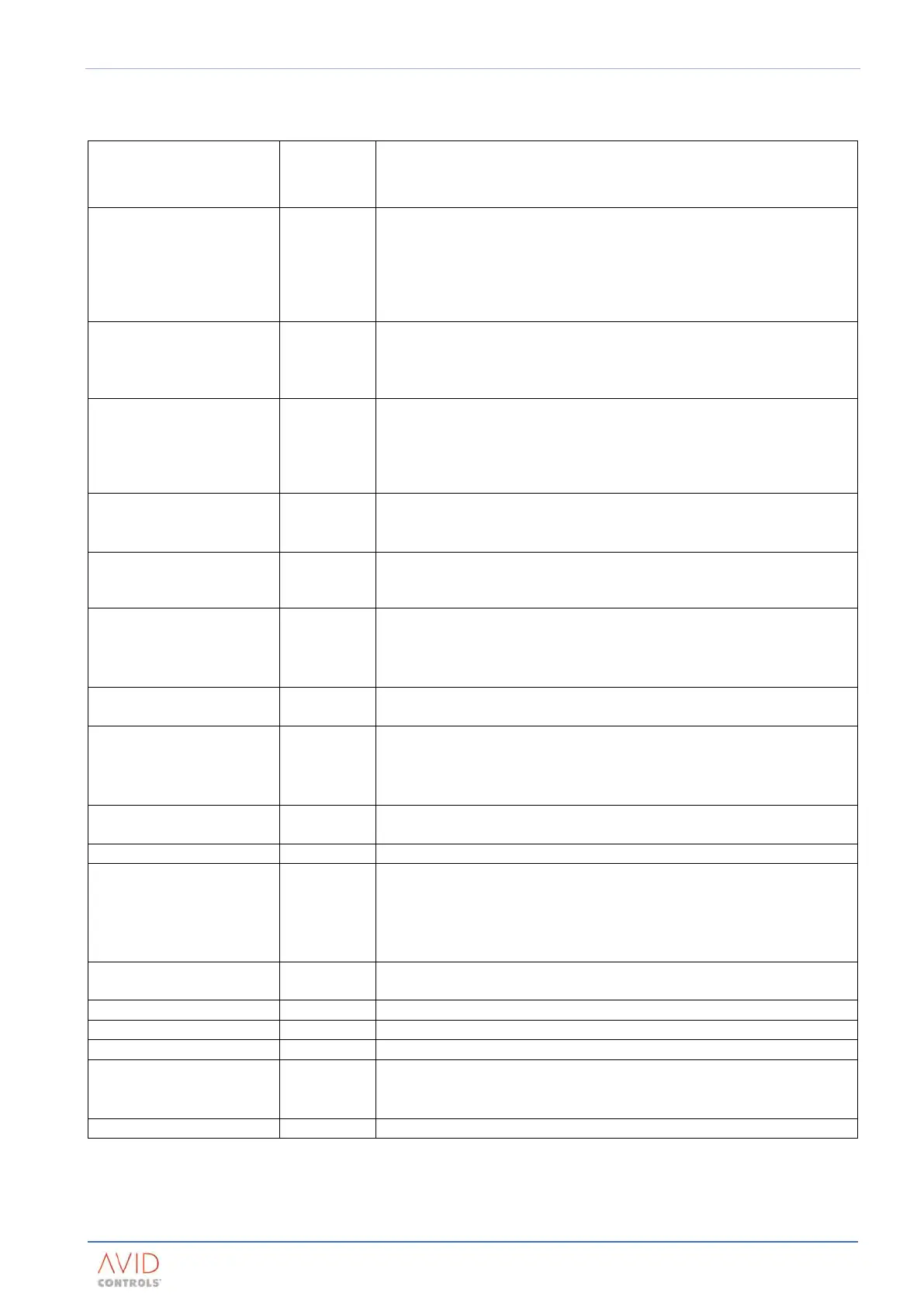

3.4.2 Items To Be Supplied By The CDM Designer / Builder

The following parts are also typically necessary to assemble the CDM:

Enclosure(s) All versions

To include gland plates, baying brackets, panel earth continuity,

apertures for cables/vents etc.

(Rittal TS8 enclosures are recommended)

Internal Panels and

Brackets

All versions

• control components;

• auxiliary components.

Mounting frame interface brackets (if Rittal TS8 enclosure is not used).

Additional panels for earthed ribbon cable highway.

Power Connections All versions

Bus ways (busbars)

Customer terminals

Control All versions

Auxiliary supplies

Internal discrete wiring

Control supplies (In addition to SMPS if required)

Terminal blocks (In addition to I/O panel if required)

Filters All versions

• PWM filter;

Cooling system All versions

Air cooling system, see Section 3.7.8

(including enclosure ventilation fans etc.)

Wound Components

(other than sharing

reactors)

All versions

• AFE main reactor;

• Filter reactors;

• Control supply transformers.

Control cables All versions

All cables and wiring other than the ribbon cables supplied with the

DELTA components, or separately supplied by GE Power Conversion.

Fuses / circuit breakers /

isolators

All versions

To provide protection for:

• AC power;

• DC power;

DC link Pre-charge circuit

Required for drives that do not use DELTA Rectifier modules.

Fixings / labels / crimps All versions

• All screws, bolts and washers that are not provided with the

DELTA products;

• User connection identification;

•

All crimps for power and control wiring.

24 V d.c. power supply All versions

To maintain communication with the controller in the absence of the

main power supply. (optional)

To protect against low temperature and/or condensation.

To protect the equipment against transient conditions

Temperature monitoring /

protection

All versions

• Enclosure ambient;

To test and commission the CDM

Loading...

Loading...