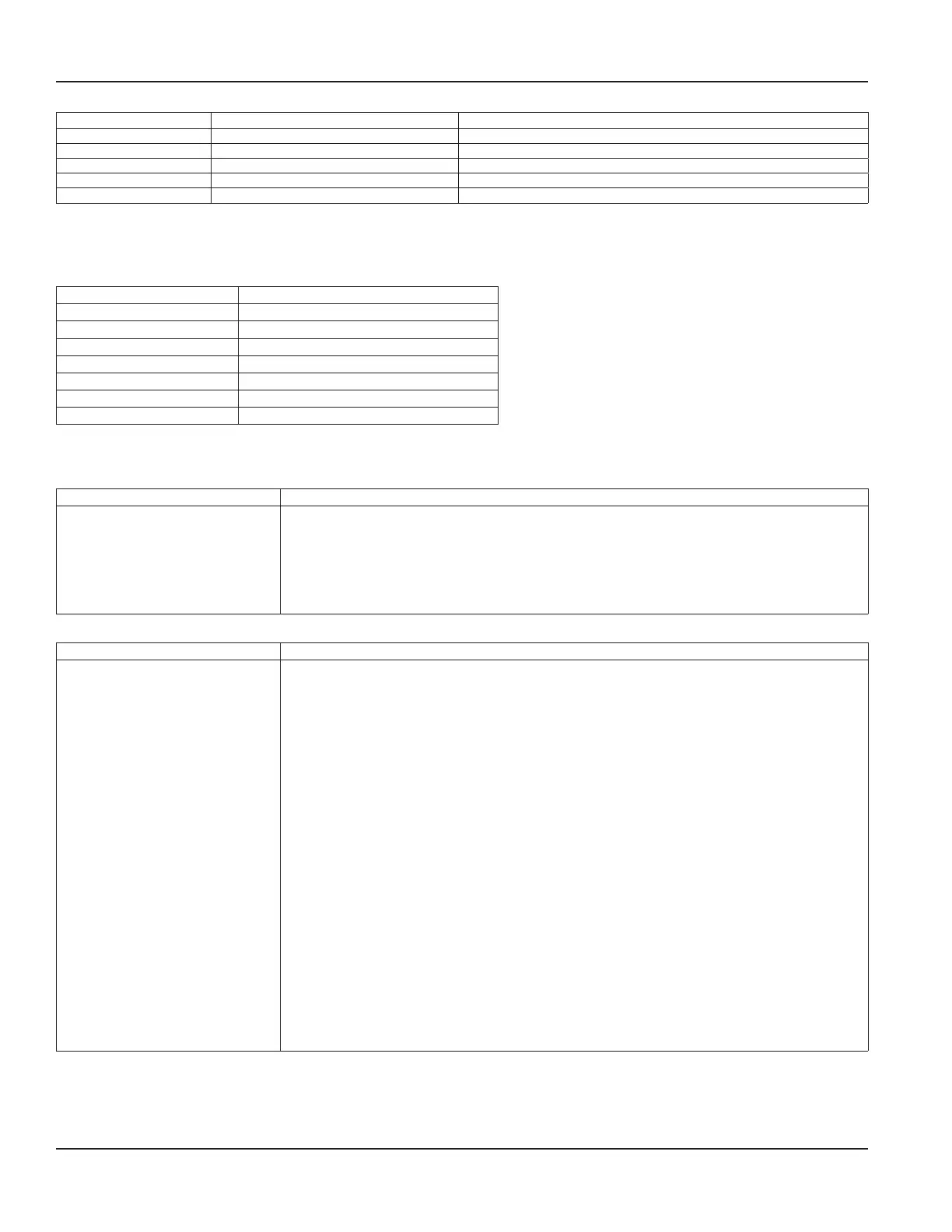

Code Description Correction

S95 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Output #1.

S96 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Output #2.

S97 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Output #3.

S98 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Aux Output #1.

S99 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Aux Output #2.

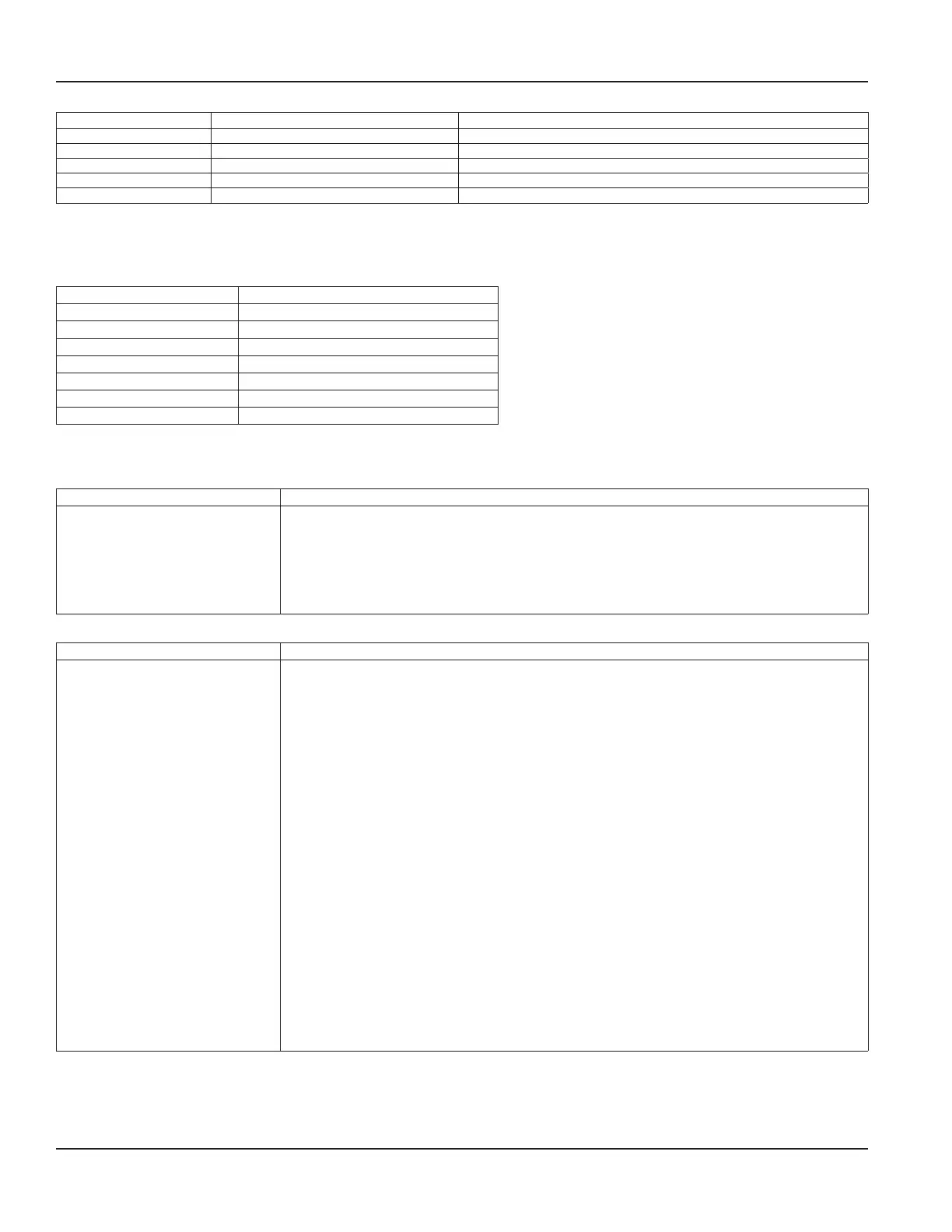

Informational Events Codes

Information events are only displayed in the ALARM HISTORY and not on the Home Screen.

Code Description

I01 POWER ON Power on or rebooted.

I11 ZERO Meter zeroed.

I12 FACTORY CALIBRATION Calibration changed from Field to Factory.

I13 FIELD CALIBRATION Calibration changed from Factory to Field.

I21 FIRMWARE CHANGED Firmware updated.

I31 FLOW TOTAL RESET Flow total reset to zero.

I41 NO SD CARD Micro SD card not installed.

Symptoms

Symptom: Transmitter does not power up.

Possible Causes Recommended Action

• No power or inadequate power

• Blown fuse (AC Model only)

• Display ribbon cable not seated

properly

• Measure voltage at the power terminals and check that the voltage matches the labels by the

power terminals.

• Check the fuse near the power terminals. If fuse is blown, verify the voltage and polarity is

correct and reset the fuse.

• Inspect ribbon cable connections. LED’s on power board will light up with no LCD display.

• Replace the transmitter if the above actions do not resolve the issue.

Symptom: Flow reading appears to be incorrect.

Possible Causes Recommended Action

• Incorrect positioning of

transducers

• Poor contact between

transducers and pipe

• Poor placement of transducers

• Low signal strength

• Process loop issues

• Incorrect pipe settings

• Meter not calibrated

• Display not set up correctly

Refer to the Transducer Mounting Configuration section for details on proper installation.

At the transducer:

• Verify that the spacing of the transducers is set correctly. On most transducers, a scribe mark on

the side of the transducers indicates the point of measurement—NOT from the end points of

the transducers.

• Verify that the transducers are aligned correctly. For Z-Mount, verify the transducers are 180°

from each other.

• Make sure there is a good contact between the transducers and pipe and a thin coat of acoustic

coupling is applied. For integral mount, check for over-tightening of the transducers.

Process loop and general location:

• Make sure the transducers are on the sides of the pipe and NOT on the top of the pipe.

• Check that the transducers are NOT located at the highest point in the loop where air may

accumulate.

• Check that the transducers are NOT on a downward flowing pipe unless adequate downstream

head pressure is present to overcome partial filling or cavitation.

• Check that the transducers have adequate straight pipe upstream and downstream.

• Check process loop for entrained air or particulates which will impact the flow readings.

• Pipes may develop scale, product build-up or corrosion over time. As a result, the effective wall

thickness may be different than a new pipe and wall thickness or liner parameters may need to

be adjusted.

At the transmitter:

• Verify that pipe parameters match the installation.

Troubleshooting

Page 46 October 2019TTM-UM-02222-EN-04

Loading...

Loading...