4. Hydraulic Theory

4.2.2 Water On/Off Valve

This valve is actuated through a coil using unregulated +24 VDC.

When the power is off, the valve is closed preventing water from

entering the Instrument. When power is on, the on/off valve

operation is controlled by the supply manifold level sensor signal.

During heat cleaning, the valve is closed. This valve can be

monitored using the DS1 “Flow Control” LED on the I/O

Hydraulics Power board (see Section 5, Electronic Theory).

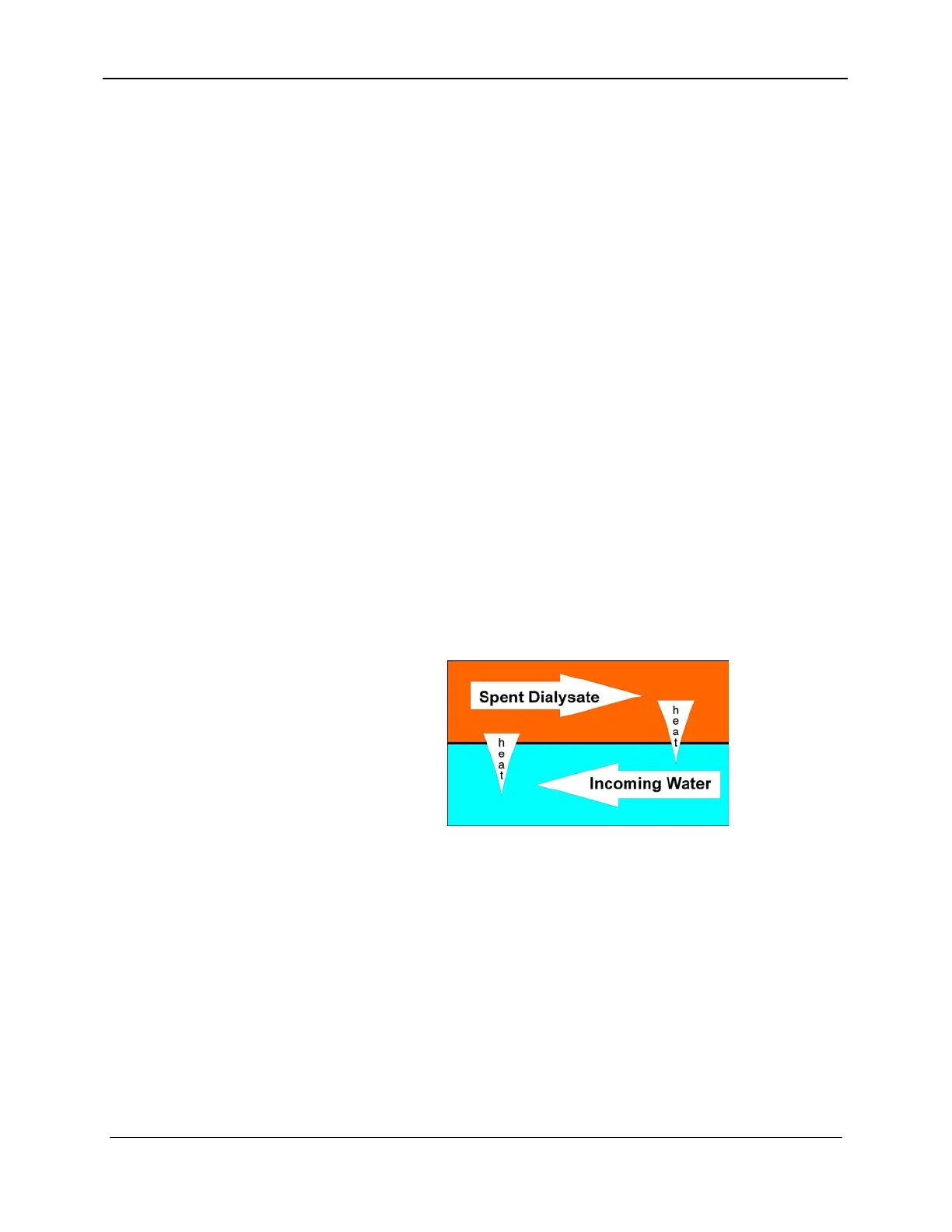

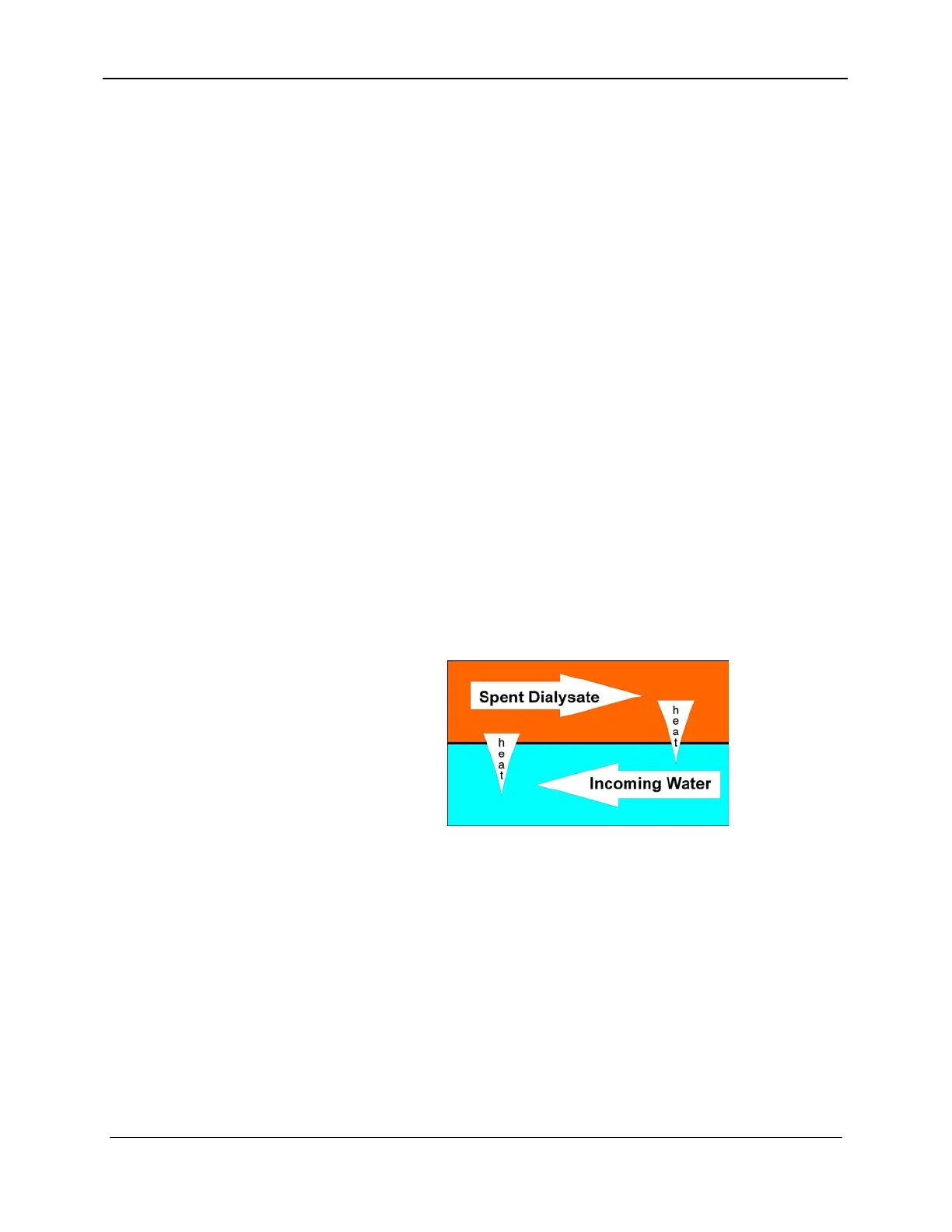

4.2.3 Heat Exchanger

Incoming water flows through a hydraulic channel on one side of a

stainless steel plate. On the other side of the plate, the spent

dialysate flows in a countercurrent direction in an identical

hydraulic channel before draining out of the Instrument.

Heat is transferred from the spent dialysate to the incoming water

through the plate. This heat transfer preheats the incoming water,

shortening dialysate warm up time. By reducing the time the

heater is on, the heat exchanger saves energy.

The heat exchanger allows the Instrument to be used with a wider

range of incoming water temperatures since this preheating of the

incoming water reduces these variations.

Figure 4-4. Heat Exchanger

4.2.4 Heater, Thermistor, Safety Thermostat

The water is heated to the desired temperature by a heater. On the

output of the heater is a thermistor. The thermistor resistance

changes in inverse proportion to temperature changes. The

thermistor sends a signal to the UF-Proportioning Power board,

which then turns the heater on or off to maintain or increase the

temperature.

Next to the heater is a resettable thermostat, which prevents the

heater from exceeding a temperature of approximately 107°C

157-1278-893 4-5

January 2004

Loading...

Loading...