235

20 08 CONTESSA

CHASSIS INFORMATION — 10

NOTE:

Due to the precise tolerances of diesel

injection systems, it is extremely

important that fuel be kept clean and

free of dirt or water. Dirt or water in the

system can cause severe damage to both

the fuel pump and the fuel injectors.

Fuel additives for lubricity are not

recommended. There are numerous

diesel fuel additives to help remove

moisture from fuel, prevent microbe

growth and to prevent gelling during

cold weather. Before adding any type

of fuel additive or extender, consult the

Manufacturer’s Owner’s Manual.

Fuel Tank

Pick-up and return lines are placed at opposite

ends of the tank to inhibit fuel aeration. The

engine pickup tube is cut at a 45° angle to allow

optimum ow to the engine. The generator and

Aqua-Hot intake tubes are set to approximately

¼ of a tank. This will prevent depleting the fuel

supply while dry camping.

NOTE:

Fill the fuel tank during storage

to reduce the amount of potential

condensation. After storage, check

the vent tube for blockage. It is not

uncommon for insects to plug the vent

tube. If pressure or vacuum exists when

the fuel cap is removed, the vent tube

may be blocked. The end of the vent

tube is located on the curbside of the

fuel tank, near the bottom.

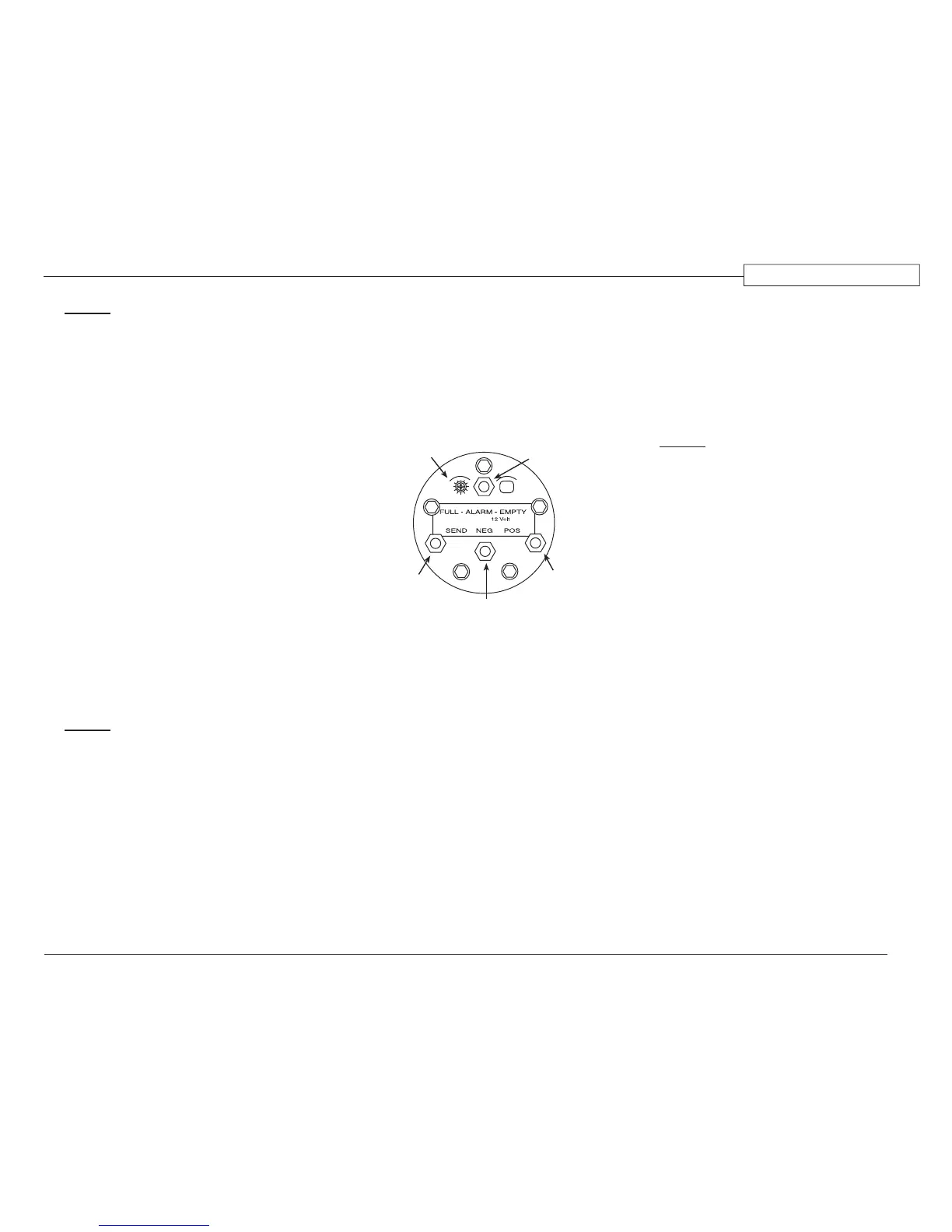

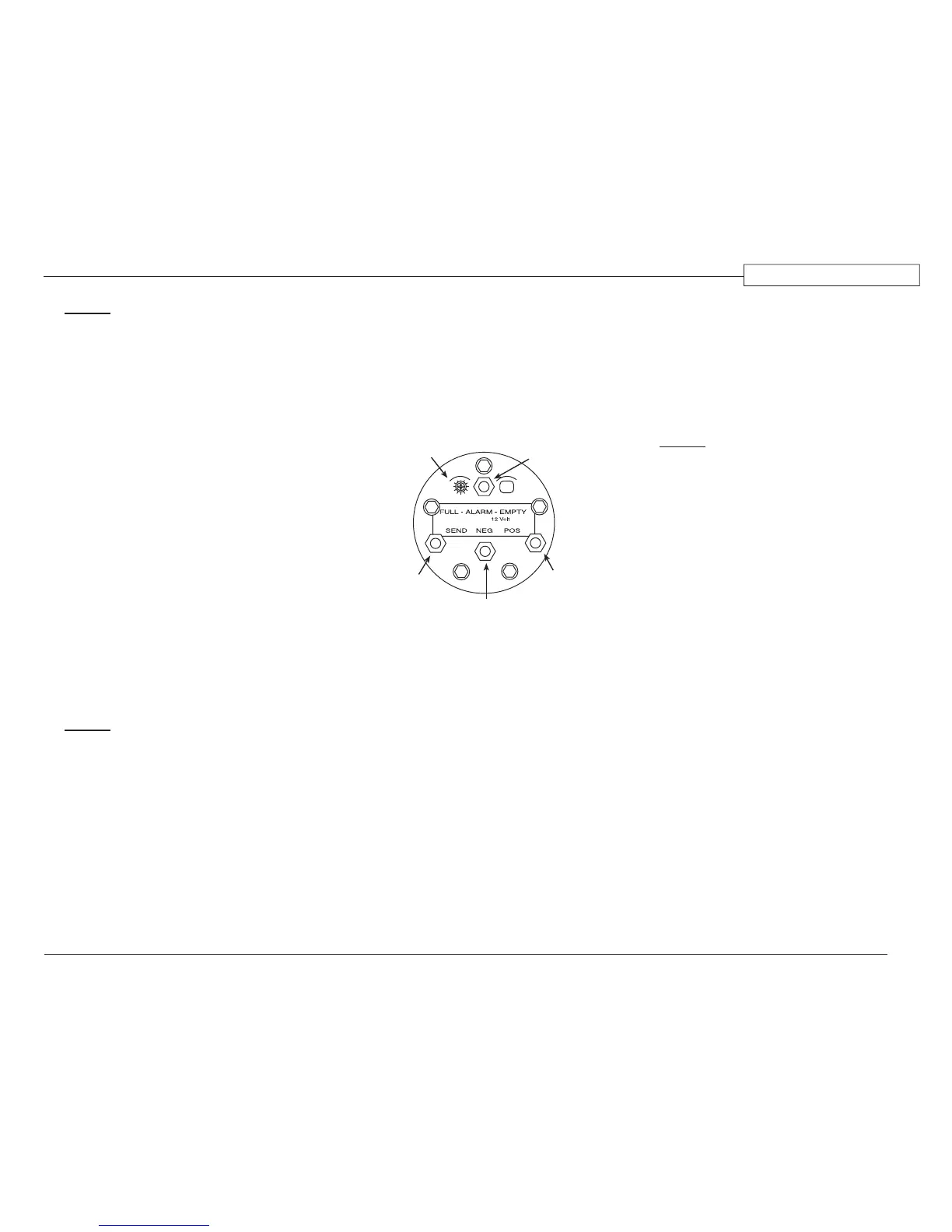

Fuel Sender

The Centroid fuel sender has no moving parts

and works by measuring between inner and

outer tubes in the tank. Electronics in the head

of the sender convert the capacitance to current

to drive the fuel gauge.

Connections:

Positive (POS) and Negative (NEG) -

Battery voltage to run the electronics in

the sender head.

Send - Connects to the fuel gauge on the

dash.

Adjustments:

Empty - Adjusts for length of sender.

It is set at the factory, covered with a

sealant and should not be changed.

Full - Used to correct for slight

differences between fuel meters. This

is factory calibrated and does not need

adjustment.

The correct adjustment technique, with a full

tank of fuel, is to start with the full adjustment

screw turned completely clockwise. This should

cause the reading to be above full. Rotate

counterclockwise slowly until the full mark on

the gauge is reached. The intent is to always

adjust downscale rather than upscale.

NOTE:

The adjustment must be made within

30 seconds of turning on power. If the

adjustment is not finished in time,

turn the power off and back on to

get another 30 seconds of adjustment

time. The sensor responds too slowly

after 30 seconds (damped output) to

allow adjustment.

Troubleshooting:

Electronic Output: The sender has a

transistorized output to prevent an

ohmmeter from getting a correct reading of

output resistance.

Fuel Only: The sender will not work

correctly in conducting uids such as water

(it will read empty all the time in water).

If there is a constant empty reading, there

may be water in the bottom of the fuel tank.

Contact Centroid: Many of the returned

Centroid units function properly on the

bench. If there are incorrect readings,

contact Centroid (telephone: 800-423-3574,

or preferably, fax: 386-423-3709) with

the symptoms. A short, “ll in the blanks”

troubleshooting test is provided to test the

sender. It is easier to nd the problem that

way than after the sender has been removed

from the system, since the problem is not

necessarily with the sender.

090318

RED:

To Gauge

WHITE:

Ground

YELLOW:

Ignition

Full

Adjust

BLUE:

Low Fuel

Indicator

Centroid Fuel Sender

Loading...

Loading...