1 695 600 968 2019-01-28| Beissbarth GmbH

Operation | MT ZERO 6 LCD | 101

8.8.2 ALU2 (PAX2) and ALU3

Fig. 74: Example of a data collection screen for ALU2 programs

Distance, rim diameter and rim width

After the automatic selection of the balancing program,

all input boxes will be automatically filled in.

i To change the values recorded for the various

menu items, press the <RIM DISTANCE>, <RIM

DIAMETER> or <RIM WIDTH> key and scroll through

the numerical values to the desired value with the

aid of the <+> or <-> key.

8.9 Manual rim data measurement

i If the rim distance and rim diameter cannot be

measured electronically, the rim data can also be

entered manually.

i Following deactivation of the electronic rim-distance

gauge, take the following steps to enter the rim

distance and rim diameter.

¶ Press the <RIM DISTANCE>, <RIM DIAMETER> or

<RIM WIDTH> key.

The data collection screen is displayed.

8.9.1 Standard, ALU1 (PAX1), ALU4, ALU5 and all

static balancing programsxxx

Distance

1. Select balancing program.

2. Position the rim-distance gauge on the rim and read

off the value at position "K" on the millimeter scale.

651127-69_Im

20

30

40

50

07 06

80

90

100

10

k

Fig. 75: Determining the distance between the rim and the

MT ZERO 6 LCD

3. Press the <RIM DISTANCE> key to change the value.

4. Use the <+> or <-> key to enter the recorded value.

Rim diameter

i The rim diameter can be determined (read off)

at the rim itself or measured with the measuring

compass.

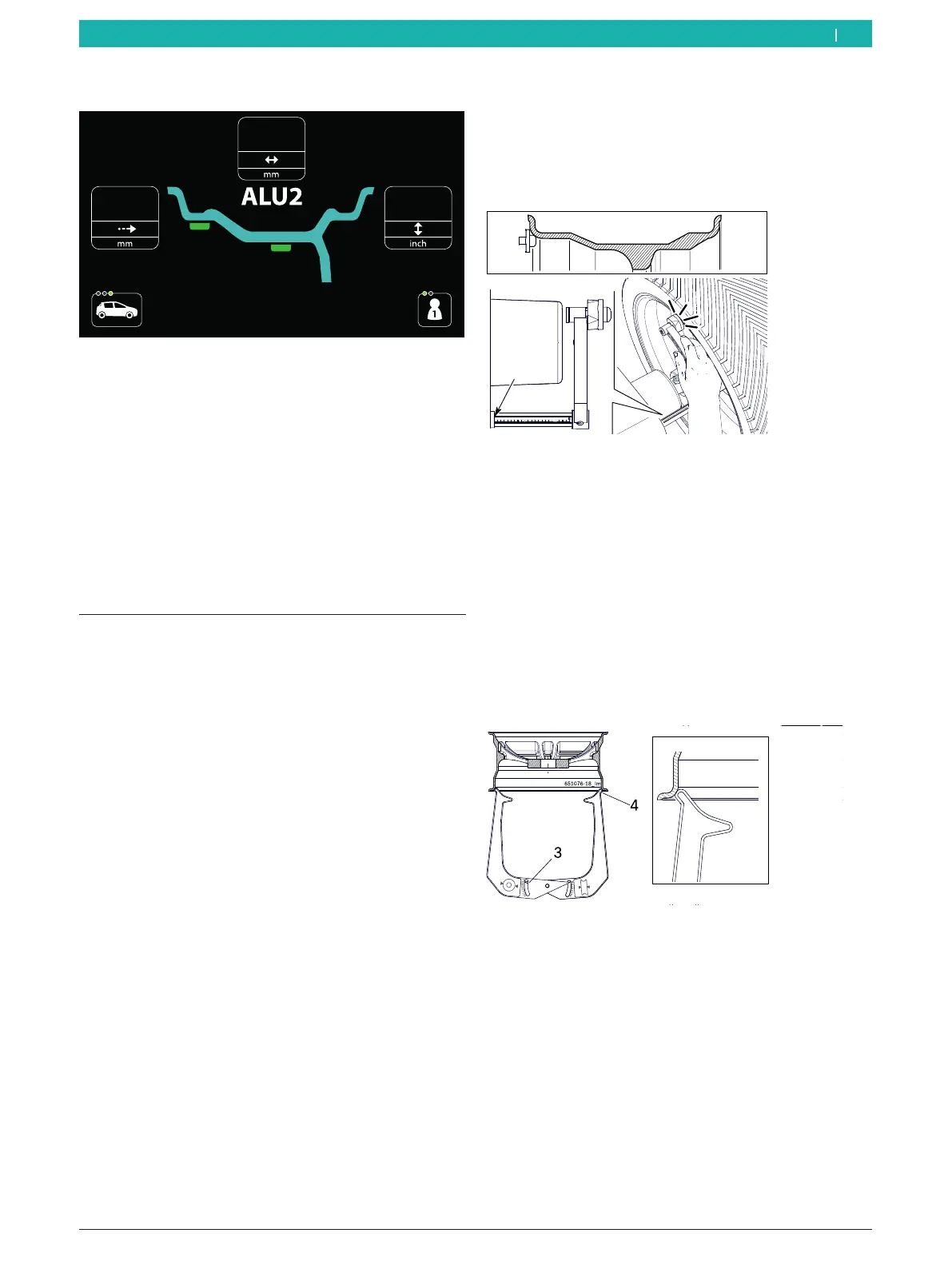

1. Position the measuring compass as shown in the

figure.

Fig. 76: Determining rim data with the measuring compass

3 Rim diameter scale

4 Outer tip for rim diameter Server

2. Read off the rim diameter.

3. Press the <RIM DIAMETER> key to change the value.

4. Use the <+> or <-> key to enter the recorded value.

en

Loading...

Loading...