1 695 600 968 2019-01-28| Beissbarth GmbH

Maintenance | MT ZERO 6 LCD | 123

12.6.6 External laser indicator calibration

i The calibration plate is required for the calibration.

i The laser will only switch on if the wheel comes to a

stop at the position for attaching the clip-on balance

weight.

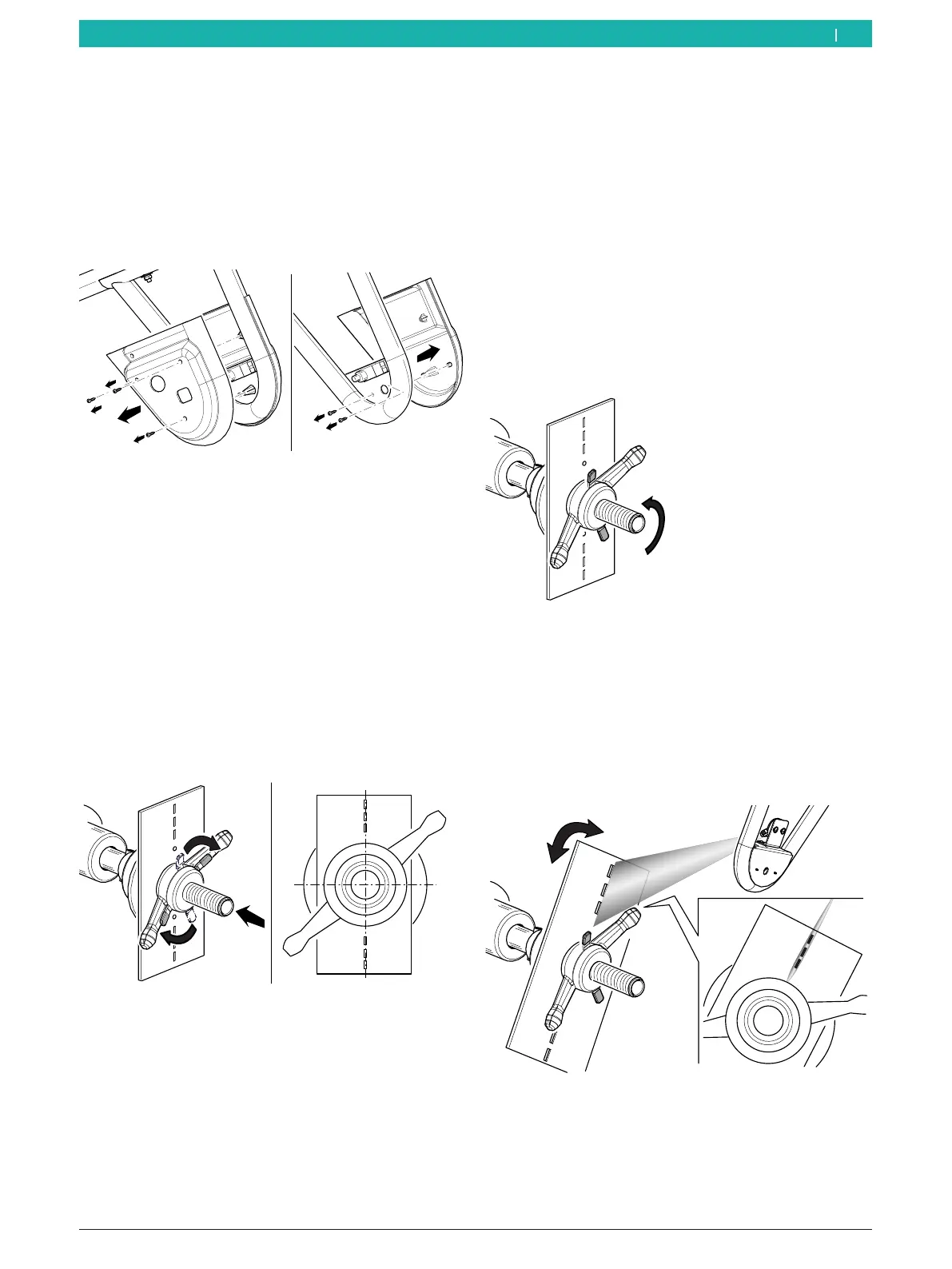

¶ Remove the cover of the sonar probe.

651127-85_BM

Fig. 106: Removing the cover of the sonar probe

The following describes 2 different procedures: one

for the mechanical version and one for the pneumatic

version.

Mechanical version

1. Remove any dirt on the flange with a wire brush.

2. Place the calibration plate included in the scope of

delivery against the flange's surface.

3. Lock the calibration plate by using a quick-clamping

ring and by inserting a small cone.

! Make sure the calibration plate is centered relative

to the flange shaft.

12

6

651127-88_BM

Fig. 107: Attaching the calibration plate

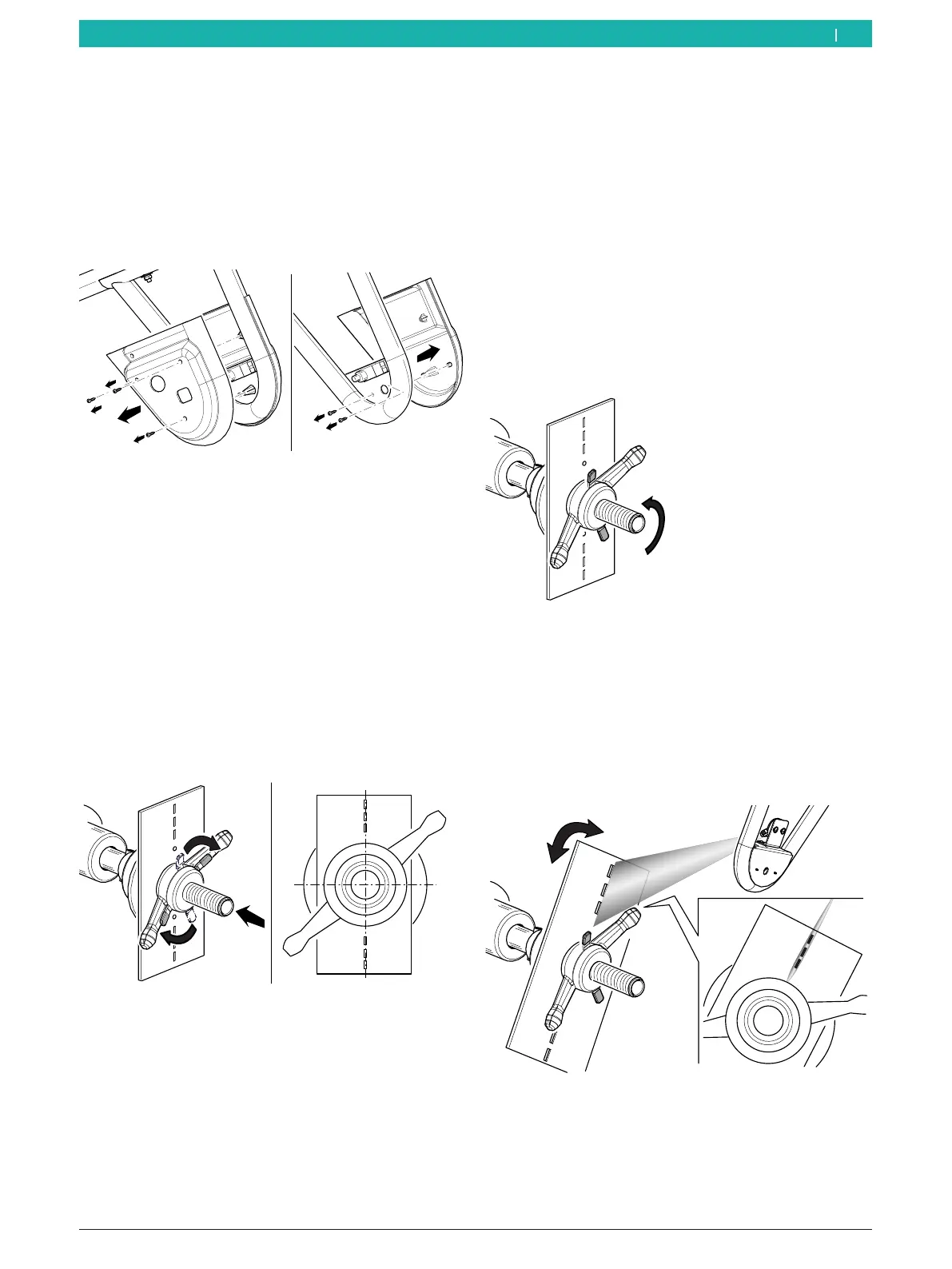

4. Close the wheel guard.

The measurement will start. Wait until the pro-

cess is completed.

After the start, the laser beam will be activated.

i Some machine versions require the wheel to be

positioned manually according to the instructions

shown on the monitor.

i During the calibration of the device, the laser beam

will be directed at the holes in the calibration plate.

5. Lift the wheel guard fully.

6. Release the quick-clamping ring to be able to turn

the calibration plate.

651127-89_BM

Fig. 108: Releasing the clamping ring

i Once the shaft rotates, the laser will be deactivated.

If necessary, reposition the shaft by hand.

7. Turn the calibration plate, and hold it in place when

it is centered across from the shaft until the beam

intersects with the holes.

651127-90_BM

Fig. 109: Laser beam being emitted

en

Loading...

Loading...