1 695 600 968 2019-01-28| Beissbarth GmbH

Initial commissioning | MT ZERO 6 LCD | 81

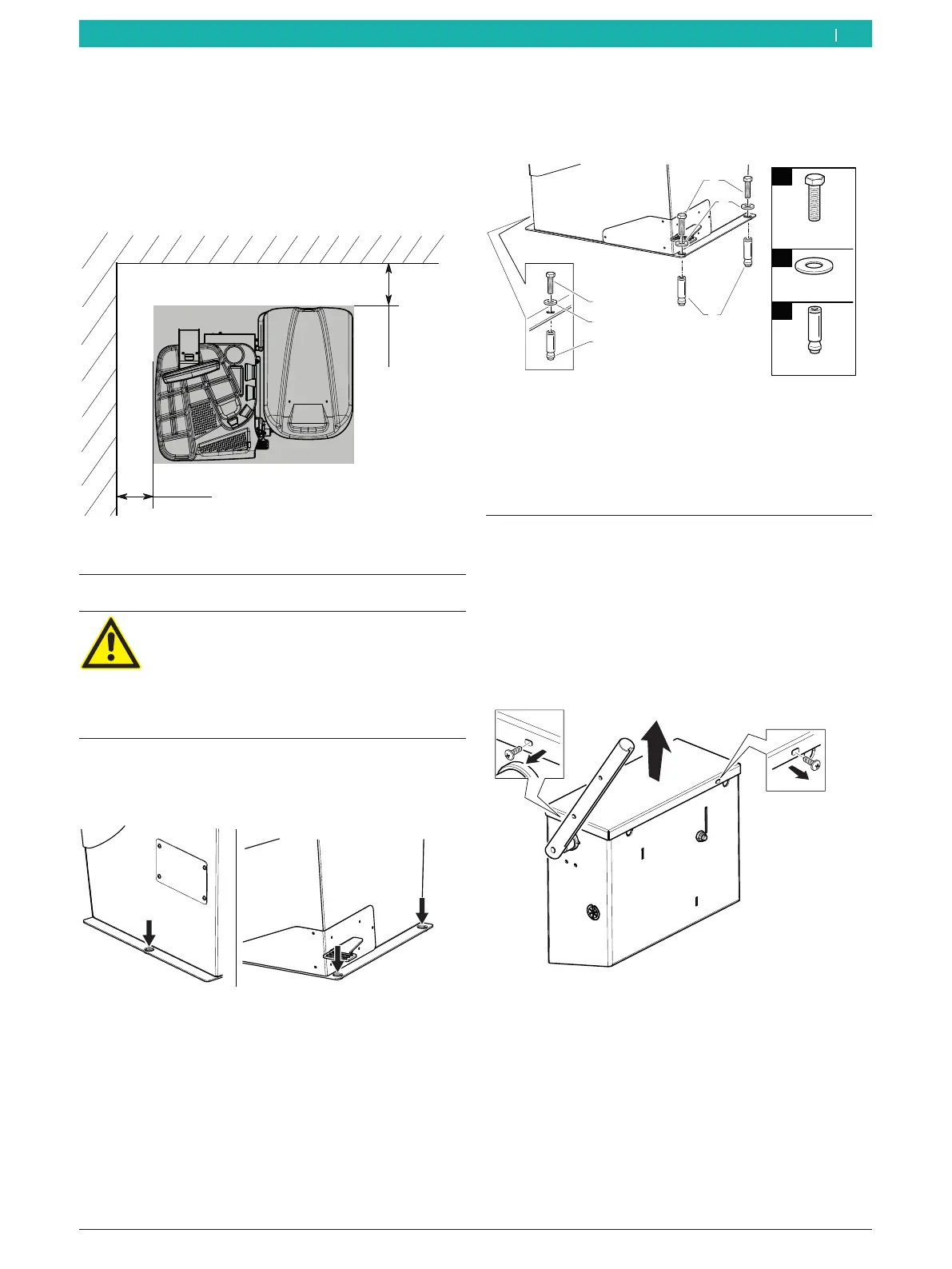

3. The wheel balancing machine must be secured to

the ground at a minimum of 3 places with screws

and dowels.

1

2

M8x70

8,5x24x4

n°3

n°3

3

Ø8

n°3

651127-11_BM

1

2

3

1

2

3

Fig. 12: Securing the MT ZERO 6 LCD

4. Insert the dowels provided, insert the washers

in between, and fully tighten them with a torque

wrench at a tightening torque of 25Nm.

5. Set up the machine in the intended area, paying

attention to the specified safe distances.

i For safe and ergonomic operation of the wheel

balancing machine, it is advisable to set it up at a

distance of 500mm from the nearest wall.

500 mm

500 mm

651115-08_BM

Fig. 10: Safe distances

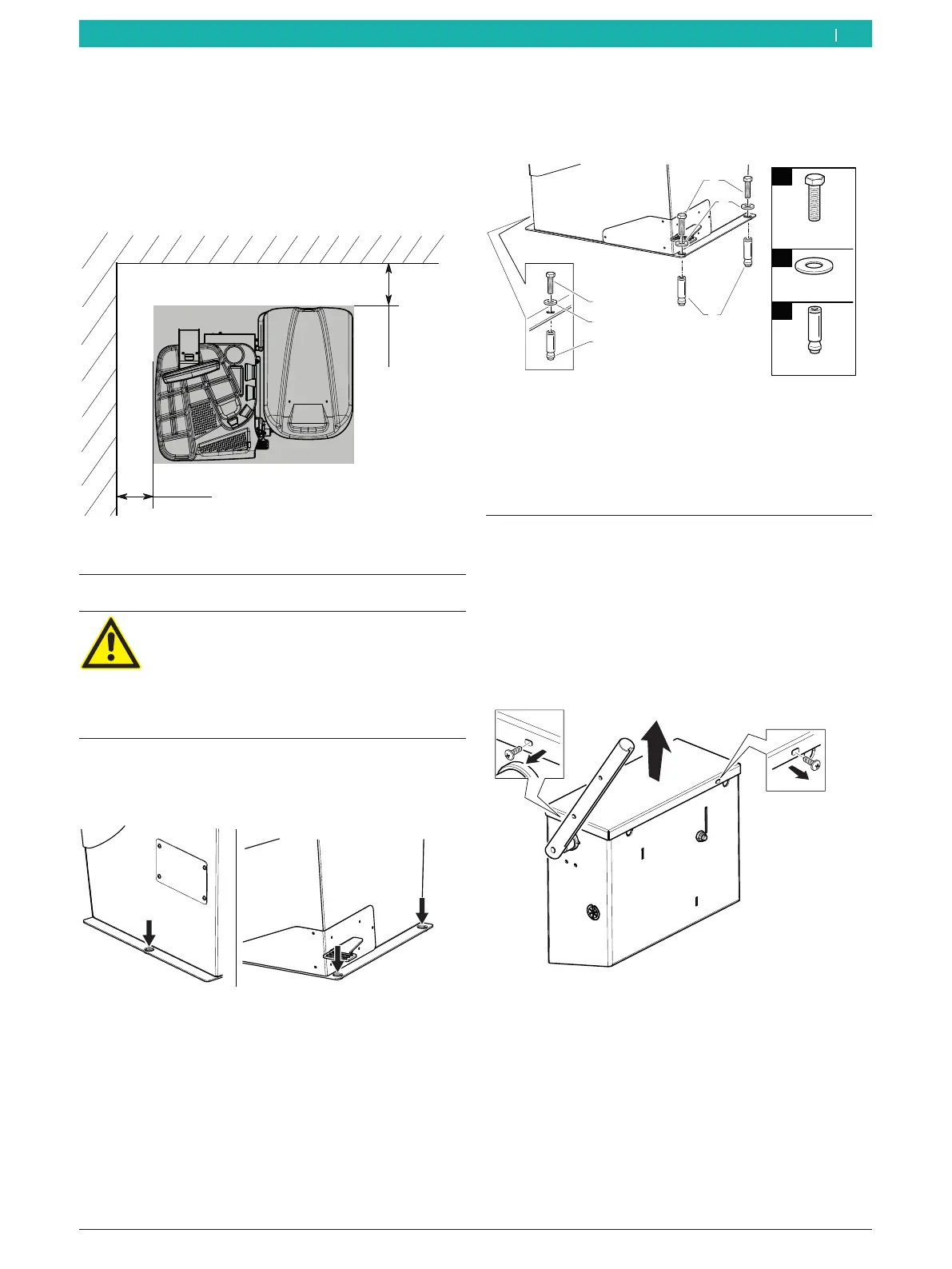

4.3 Floor mounting

Warning – danger of tipping!

Considerable forces are involved in the wheel

balancing process.

¶ Before using the machine, it is essential

to fasten it to the ground according to the

manufacturer's specifications.

1. Place the MT ZERO 6 LCD on the ground at the

intended final location. Use the bore holes in the

base of the machine for orientation.

651127-10_BM

Fig. 11: Overview of mounting holes

2. Position a power drill with a 14-mm bit, and drill

holes 65mm deep.

! We recommend cleaning the hole carefully before

inserting the dowel.

4.4 Installing the wheel guard moving

unit

i The screws for securing the unit are already

attached to the MT ZERO 6 LCD.

1. Remove the screws for securing the cover of the

unit's casing.

2. Remove the cover.

651127-12_BM

Fig. 13: Removing the cover

en

Loading...

Loading...