1 695 600 968 2019-01-28| Beissbarth GmbH

Maintenance | MT ZERO 6 LCD | 119

12.5 Diagnosis

i The diagnostics menu is used for maintenance

carried out by customer service. The user has no

access to any of the menu functions but can call up

the statuses of the elements displayed.

1. Press the <MENU> key.

The first menu level will be called up.

2. Select the "User diagnostics" menu item by

navigating through the options with the aid of the

<–> or <+> key.

3. Press the <MENU> key to confirm.

The user is requested to enter a password.

4. Enter and confirm the password 2857.

" The user diagnostics function is opened.

i If machine malfunctions are reported or noticed

during use, run a self-diagnosis.

12.6.1 Calling up the calibration menu

i Sound and automatic start are active in the following

description.

1. Press the <MENU> key.

2. Select the "Calibration" menu item by navigating

through the options with the aid of the <–> or <+>

key.

3. Press the <MENU> key to confirm.

The user is requested to enter a password.

4. Enter and confirm the password 2857.

" The calibration options are presented.

12.6.2 Calibrating the flange

i Follow the instructions on the monitor.

1. Fit the flange.

i Do not attach a wheel.

i On the mechanical version, do not use a clamping

device.

i On pneumatic versions, install the spacer plate and

secure it on the machine shaft.

2. Calling up the calibration menu

The calibration options are presented.

3. Select the "Flange calibration" menu item by

navigating through the options with the aid of the

<–> or <+> key.

4. Press the <MENU> key to confirm.

The calibration process will start.

5. Close the wheel guard.

The measurement will start.

i Calibration can be exited, at any time without saving

the settings by pressing the <STOP> key.

en

12.4.4 Changing the oil in the oil mist lubricator

1. Remove the compressed-air connection.

2. Unscrew the container on the oil mist lubricator.

3. Drain and dispose of the oil.

4. Top up with fresh oil.

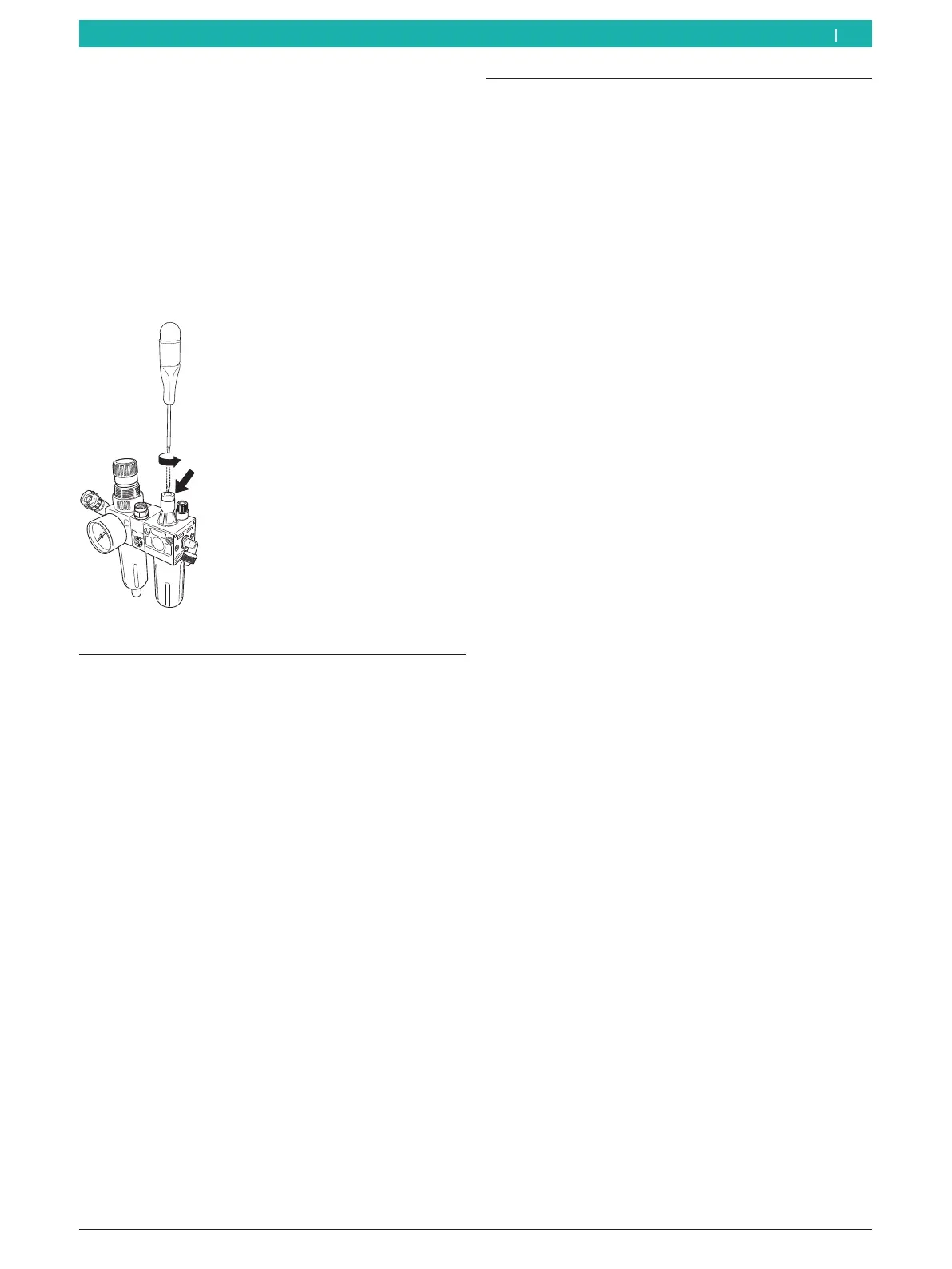

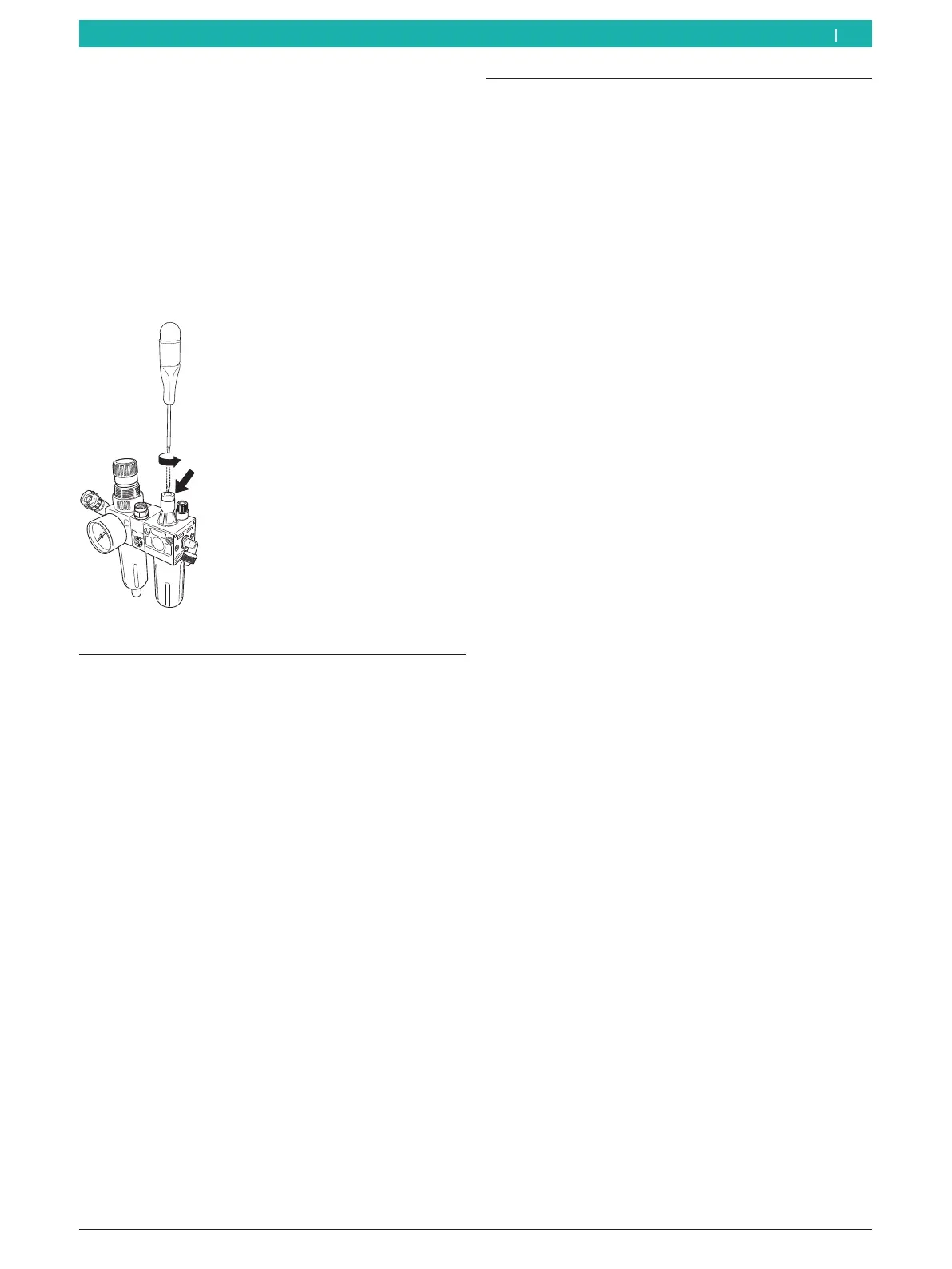

12.4.5 Setting the lubricating oil flow

1. Unscrew the container on the oil mist lubricator.

2. Use a screwdriver to set the screw indicated by the

arrow in such a way that 1 drop of oil emerges for

every 3 opening and closing operations of the flange.

652047-12_Mi

12.6 Calibration

i As part of service and upkeep (every six months), on

flange replacement or in the event of measurement

inaccuracies, it is advisable to calibrate the

MT ZERO 6 LCD in the following sequence:

1. Calibrate the flange.

2. Calibrate the electronic rim-distance gauge and the

sonar probe.

3. Use a wheel and a balance weight for calibration.

4. Perform a reference measurement.

5. Calibrate the external laser indicator.

Loading...

Loading...