1 695 600 968 2019-01-28| Beissbarth GmbH

118 | MT ZERO 6 LCD | Maintenance

12. Maintenance

12.1 Cleaning and maintenance

! Before cleaning and maintenance, switch off the

MT ZERO 6 LCD and disconnect the mains plug.

! Do not use any solvent-based cleaning agents. Use

alcohol or similar cleaning agents to clean plastic

parts.

12.2 Service intervals

To ensure proper operation and performance of the

MT ZERO 6 LCD, carry out the following work in the

specified intervals:

Maintenance

Once a week

Semi-annually

Annually

Clean off the moving mechanical parts, use spray

oil or kerosene to clean them thoroughly, and

lubricate them with lubricating oil or a suitable

grease.

x

Remove condensate.

x

Check the oil level in the oil mist lubricator.

x

Calibrate the flange.

x

Calibrate the electronic rim distance gauge.

x

Calibrate the sonar system.

x

Calibrate the MT ZERO 6 LCD.

x

Perform reference measurement.

x

Calibrate the external laser.

x

Change the oil in the oil mist lubricator.

x

i The calibration process is described in the

"Calibration" section.

12.3 Spare and wearing parts

The manufacturer cannot accept any liability for

damage arising from the use of non-genuine spare

parts.

Designation Order no.

Spacer plate 1 695 653 212

Centering cone, 42–64.5mm 1 695 632 500

Centering cone, 54–79.5mm 1 695 652 862

Centering cone, 74–111.5mm 1 695 605 600

Centering cone, 120–174mm 1 695 606 300

Balance weight holder 1 695 606 500

Manual vernier caliper 1 695 629 400

Measuring compass 1 695 602 700

Balance weight 1 695 654 377

Balance weight, calibrated 1 695 654 376

Designation Order no.

Electrical-voltage label 1 695 100 789

Laser safety label 1 695 654 484

Laser source label 1 695 600 941

Tab. 4: Spare and wearing parts

en

12.4 Maintenance work

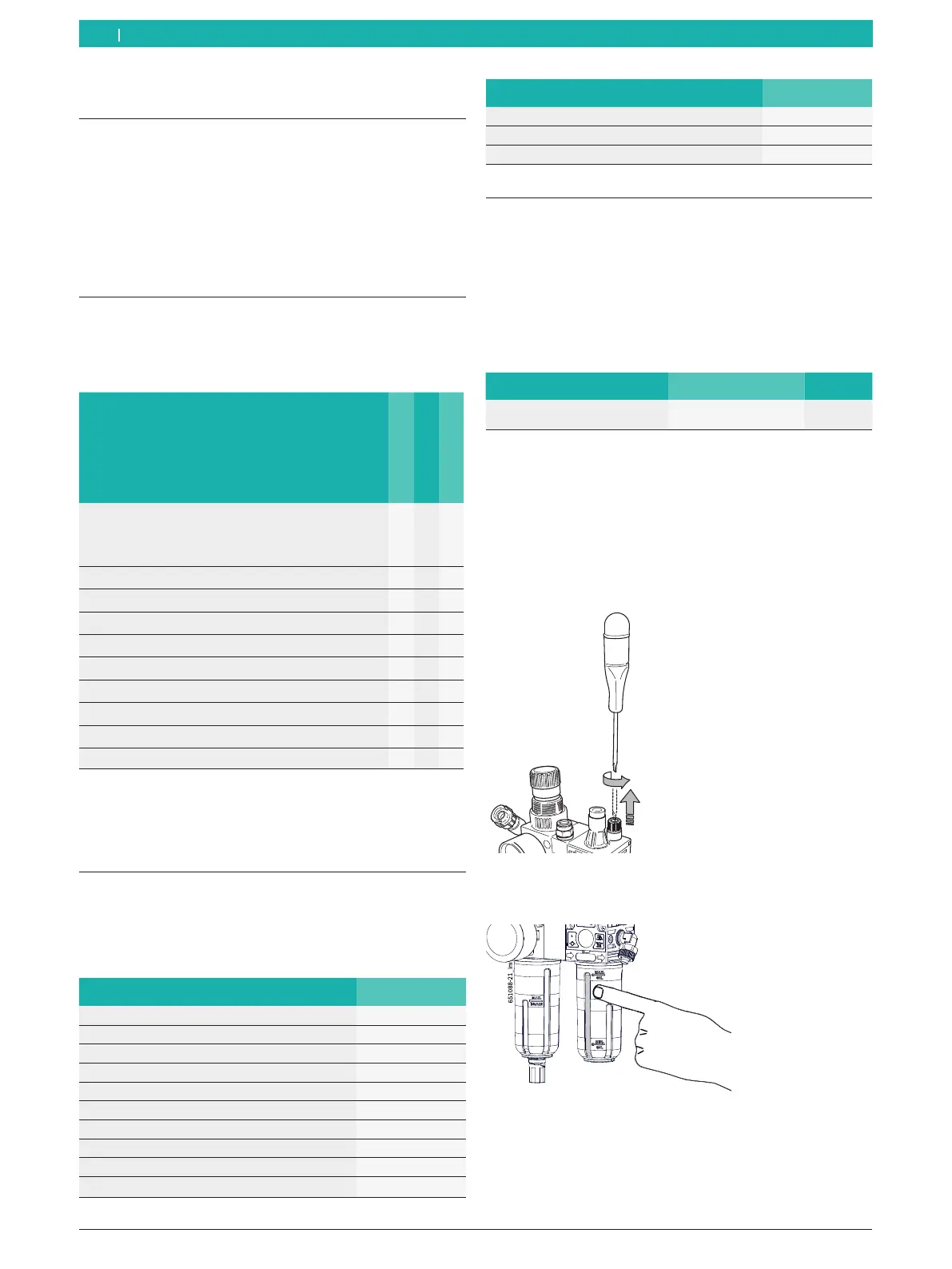

12.4.1 Removing condensate

1. Turn the red knob at the bottom of the water

separator counterclockwise.

2. Remove the accumulated condensate.

3. Turn back the red knob on the water separator.

12.4.2 Recommended oil mist lubricator lubricants

Item/component Lubricant Standard

Pneumatic system ESSO FEBIS K32 ISO32

Tab. 5: Lubricant table

! The manufacturer does not accept any liability for

damage arising from the use of different lubricants.

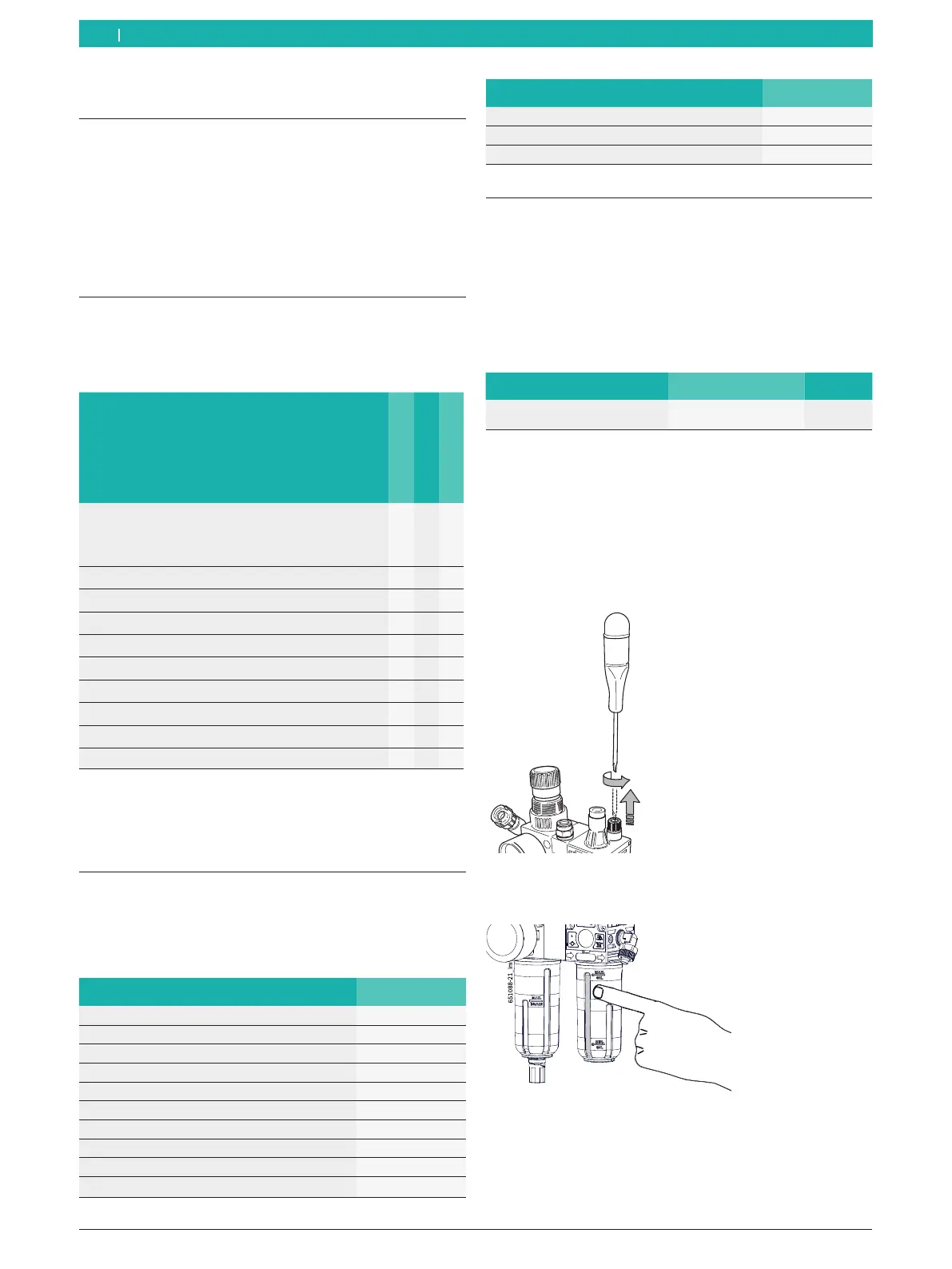

12.4.3 Topping up the oil in the oil mist lubricator

1. Remove the compressed-air connection.

2. Unscrew the container on the oil mist lubricator.

3. Top up the oil mist lubricator with fresh oil to the

maximum level.

Loading...

Loading...